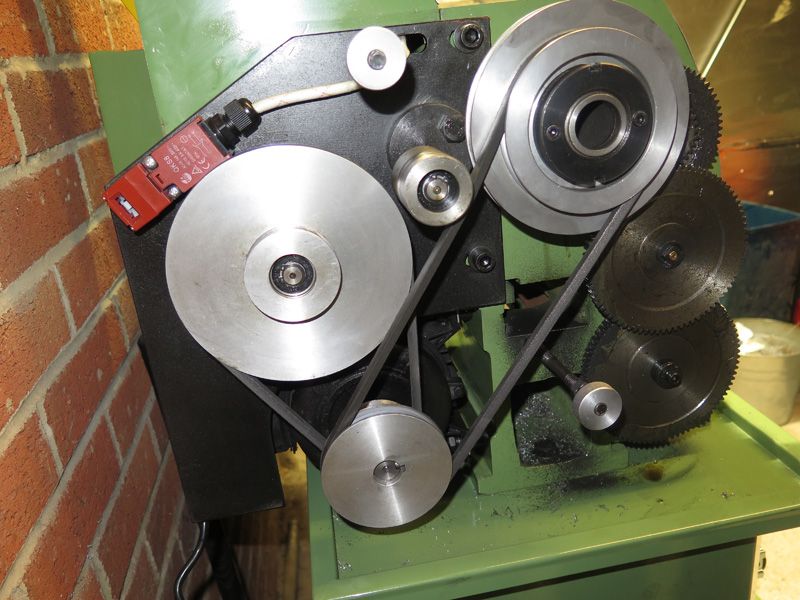

With the WM250 V-F out of its twelve month warranty but still under two years old from new I am reluctant to spend yet another £277 (or maybe more) on another repair which may or may not work.

You seem to be falling for the old myth of the 12 month warranty. That was scrapped many years ago, although the retailers often want you to forget that. In the modern world, it's only in North America that that 12 month warranty still has currency. Here in the UK, AFAIK we have something up to 6 years, depending on the product. I certainly wouldn't expect to be repairing / replacing a machine tool after 12 months.

You should be more robust with Warco. If necessary, contact the local trading standards for advice. Warco should be talking about how they will repair or replace the faulty parts. Certainly sounds like a manufacturing or design fault which they are liable for, unless they can show you have abused or modified the product.

You should also post here to let us know how you get on. If they don't offer decent after sales support and / or products that are reliable, we should all be warned.

Murray

mechman48.