Info'

Whether you have a WM180/250/280 I would double check the bolts holding the top slide to the crosslide as I have had to do repairs to my 250 V-F just recently. I was checking my compound slide alignment as I wasn't sure how good / accurate the fiducal line on the crosslide was in relation to the zero on the compound slide scale, so setting up a test bar & DTI I wound the compound to one end of its travel, zeroed the DTI & wound the compound back to the other end of its travel. Needless to say it didn't register 'zero'.>>

After a couple of tries I got everything lined up to the test bar '0 – 0' along the compound slide travel,lightly nipped the clamping bolts to hold in place & checked the zero on the scale…no it didn't line up with the fiducal line on the saddle..well it is Chinese & their QC is s**t at the best of times. 'you gets what you pay for' blah, blah! it transpires that the fiducal line is not at 90* to the front edge of the saddle & correspondingly the zero (now set) does not match… am I too pendantic to ask for proper zero setting reference from manufacturers?

So now I nips up the clamping bolts using the supplied open ended spanner… & you know when something doesn't feel right! …just didn't feel like they were tightening as they should… off come the nuts (now having upset my zero setting! lo & behold… threads fxxx***… .oops, stripped… again typical example of Chinese crap metal, I would be loathe to class them in the basic EN1 class… mmmmm! I wonder if they could be EN1B (leaded?) which would make them 'softer' for easier machining..I diversify! I have ended up making BMS T nuts & using 8.8 bolts with a light skim off the head to allow the compound slide to rotate freely, reset the zero again & snugged the new bolts up… much better all round! will still have to centralise the fiducal line on the saddle…..

Honest! … only ever snuged them up with the spanner supplied in the kit, on the rare times I've moved the topslide.

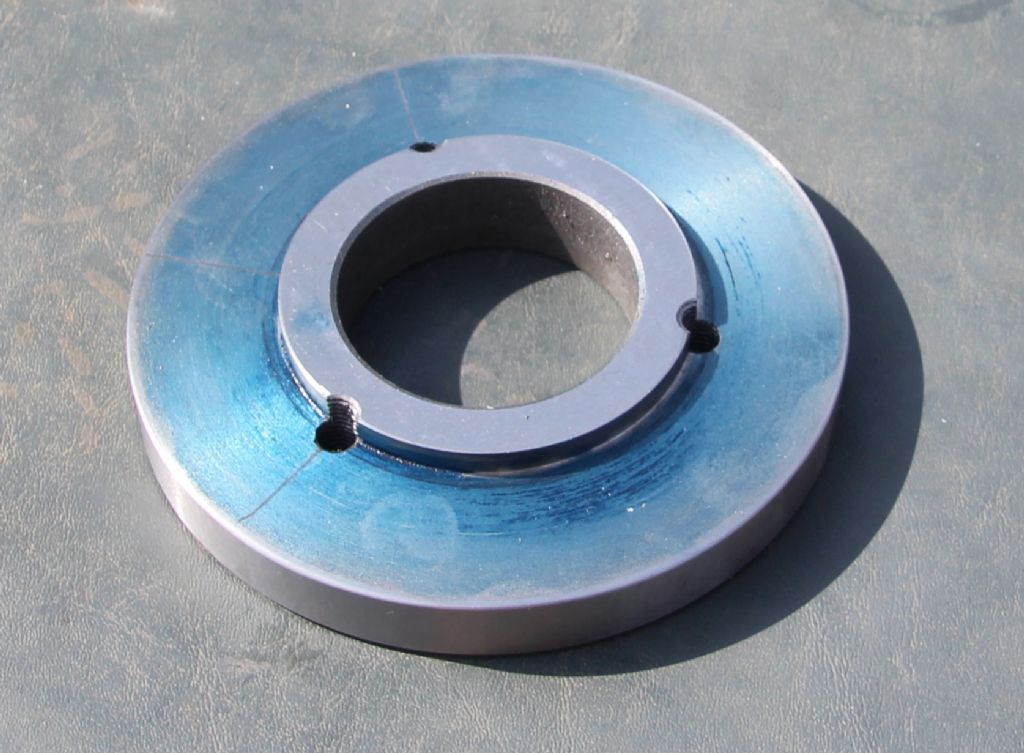

T Nut Machined…(drilled & cut into 2 later)

Neat sliding fit…

Bolt head skimmed …

All snugged up…

Zero set to test bar… fiducal line awry…

Difficult to see but the zero & fiducal line don't match, (toduit list !)

So guys 'n' gals after my diatribe just a point to check on your machine/s, wouldn't like to think of the compound slide coming loose & moving when there's a cut going on due to some crappy bolts, maybe you've had this issue & resolved it? all the better, but for newbies & those upgrading or buying this type of lathe…

Cheers

George

Edited By mechman48 on 19/07/2013 19:58:11

Edited By mechman48 on 19/07/2013 19:58:36

Cabinet Enforcer.