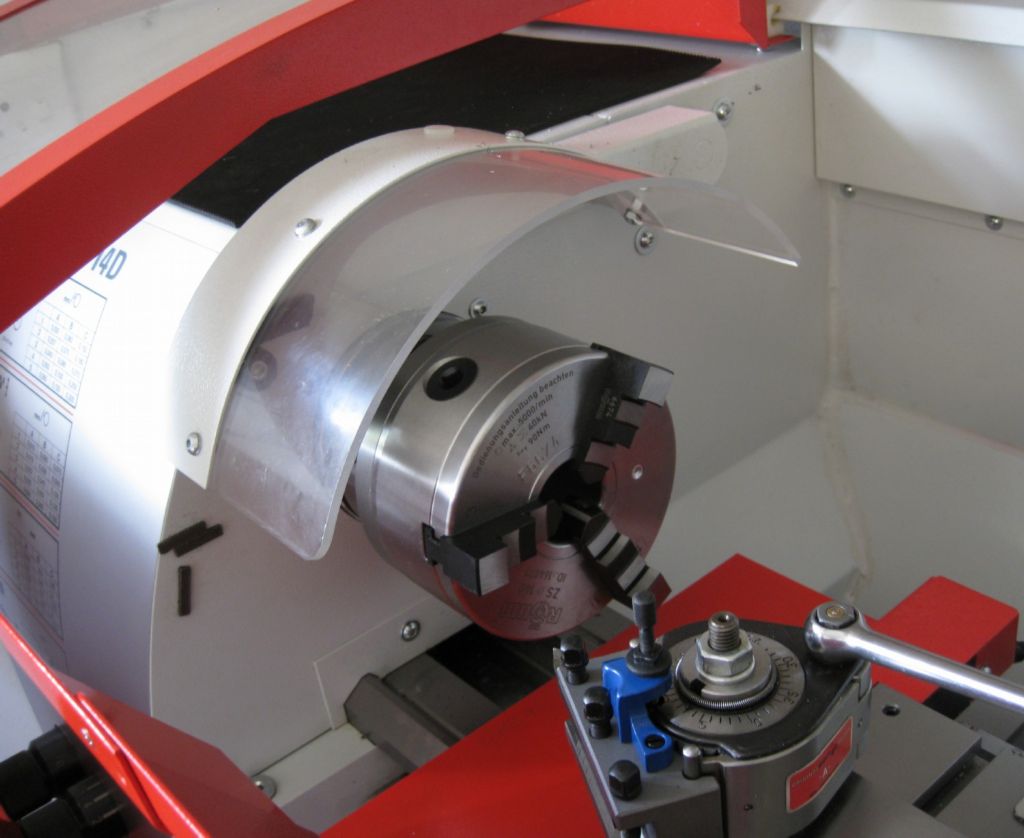

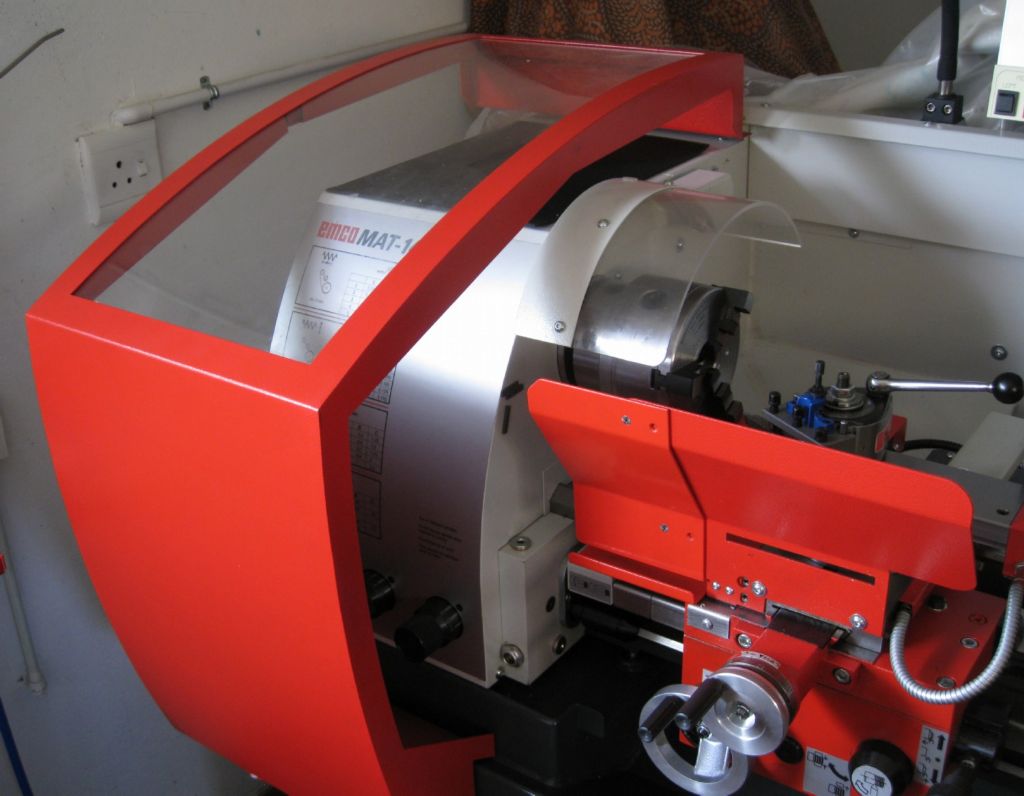

Since we are discussing moditying/removing chuck guards, My BL 12-24 (and probably Warco BH600 and Chester craftsman also) a) fouled the Faceplate and b) with my 4 way back toolpost fitted prevented working close up with the Faceplate or ER Collet Chucks.

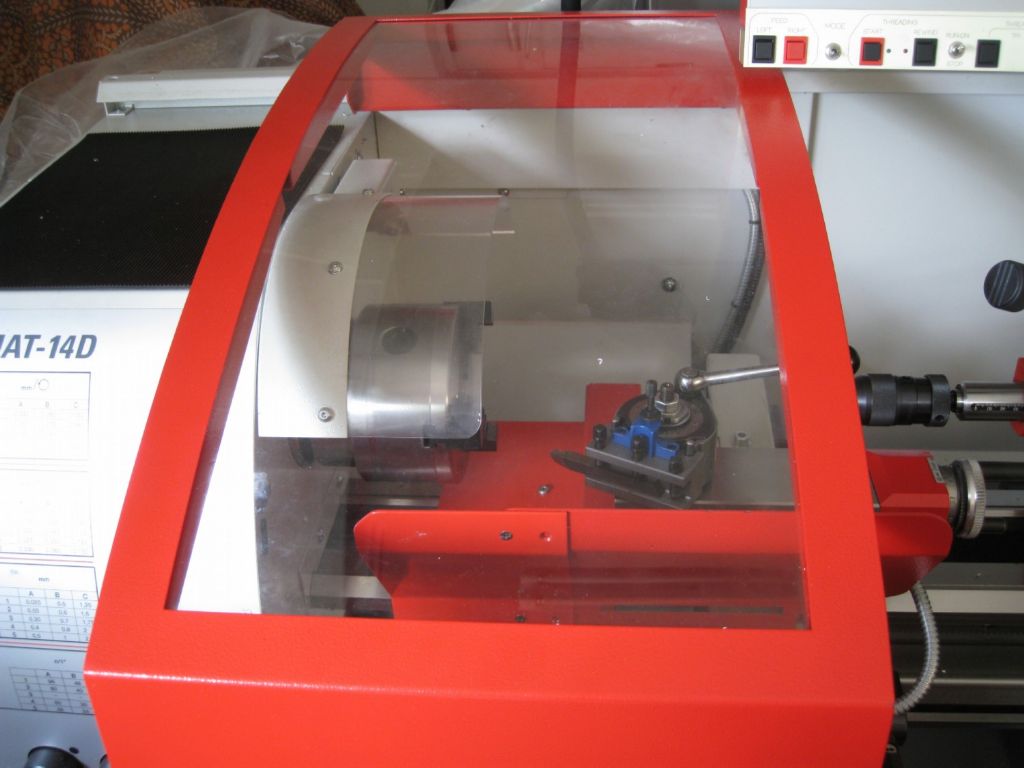

The Faceplate foul was cured by cutting away the area of the Acrylic fouled the Faceplate, to provide slight clearance. The problem of working close up still remained.

The solution was to make the guard easily removeable. This involved removing the guard, and the shaft carrying the cam that operated the microswitch. To enable the machine to run, it was wedged, as a temporary expedient, with a washer.

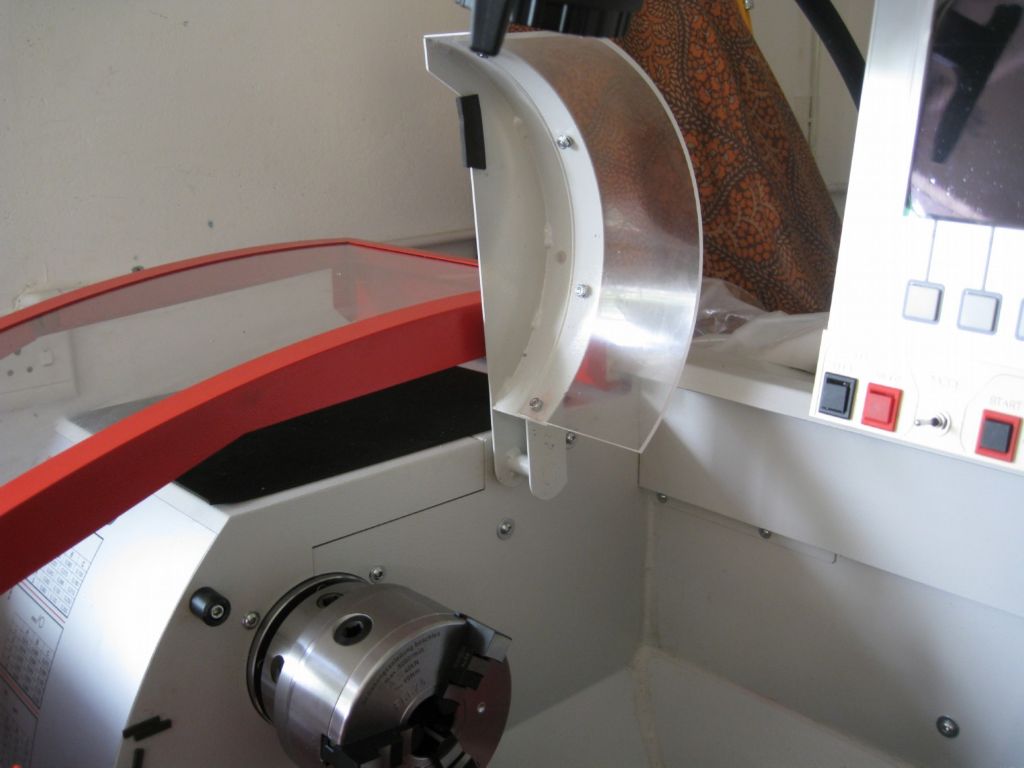

Once the guard was off the shaft, the shaft was parted off halfway along the section protruding from the housing. A sleeve was turned up, long enough to cover both parts of the shaft, and bored to be an easy sliding fit over the shaft.

The sleeve was drilled and tapped, at one end, to take the guard, and at the other, to clamp into the cam end of the shaft . Having refitted the shortened shaft, it was dimpled the provide a location for the screw that clamped the sleeve to the operating end of the shaft.

Now, if there is a need to work close up to the Headstock; for that time; the guard is closed, (so that the machine can run) and the clamping screw slackened, so that the sleeve carrying the guard can be removed. Once the work is completed, the sleeve and guard are slipped over the shaft again, and the clamp screw tightened into the dimple. "Normal service is then resumed"

Howard

FMES.