Hi

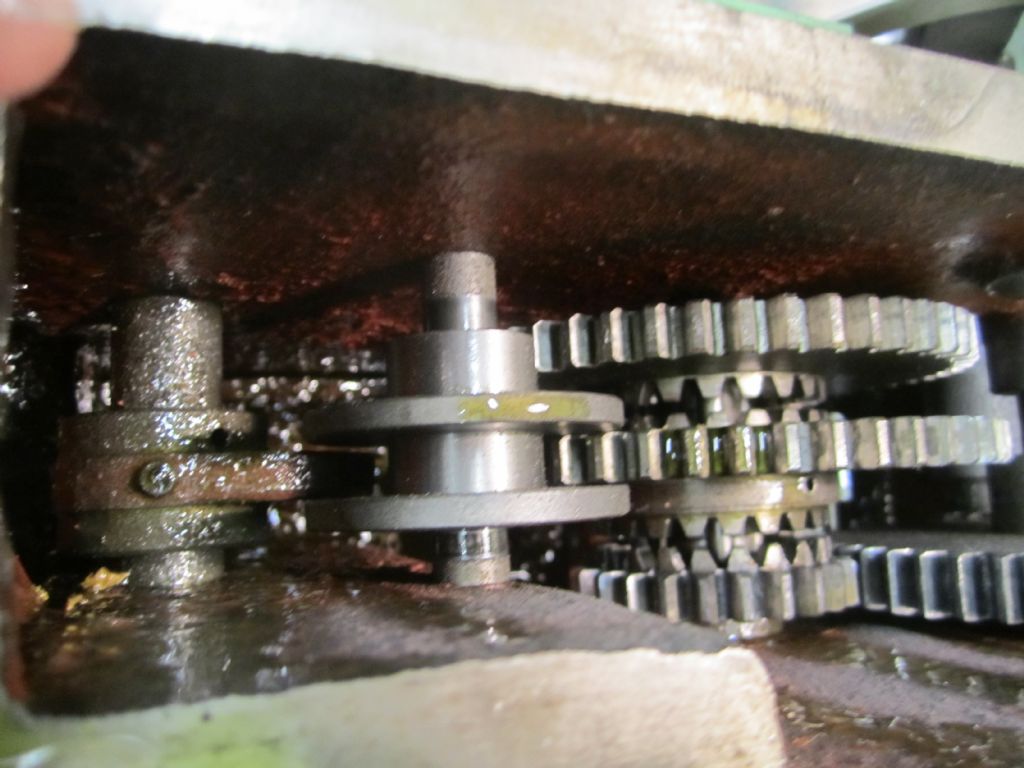

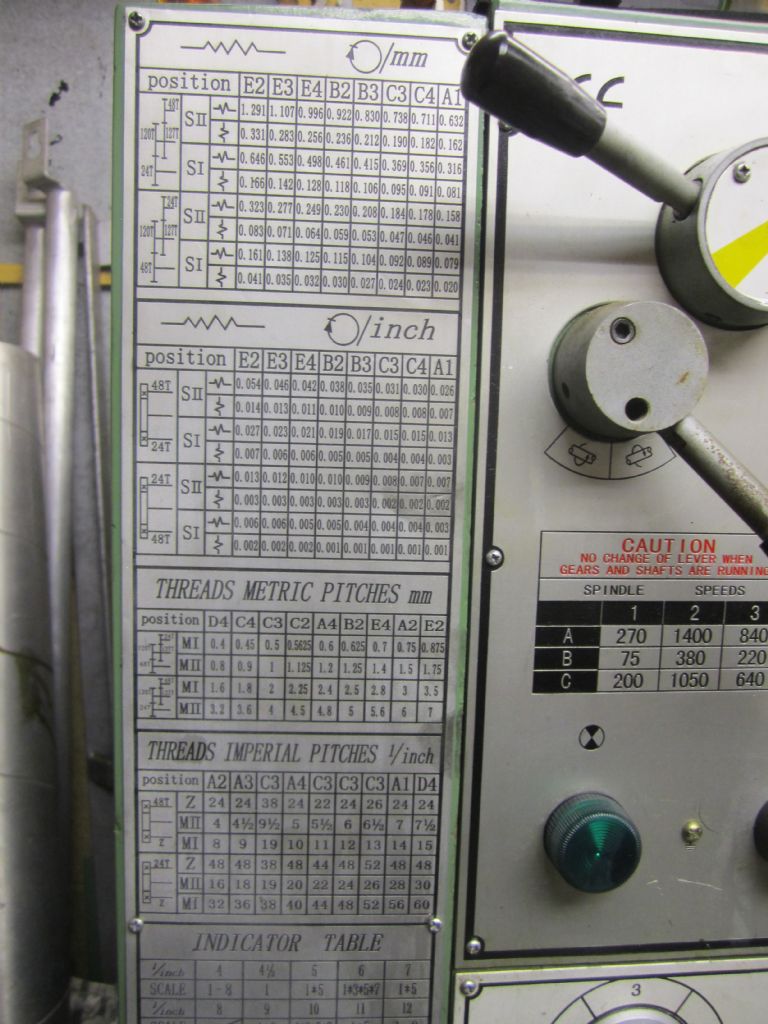

First of all I notice that you have a 127 gear listed in the change gears and this gives you a direct conversion for cutting in either metric or imperial pitches (5 x 25.4 = 127) so there is, unlike some smaller machines including mine, no approximation on thread pitches.

To cut a thread, using the longer method, back the saddle to the right until the tool is clear of the work piece. Set the depth of the first pass cut using the cross slide and if you can lock the cross slide; again make sure that for each pass you advance the cross slide thereby moving the tool into the cut so as to eliminate the backlash.

With the half nuts disengaged and the thread indicator engaged move the saddle, by hand, until a particular index marker on the thread indicator aligns with the datum mark. Close the half nuts if they won't close select another marker and repeat. It may be that you will need to adjust the reference point until this happens. LEAVE THE THREAD INDICATOR ENGAGED FROM NOW ON.

Start the lathe and the saddle should start to traverse taking the tool to the work piece. The thread indicator should not rotate at this stage. At the end of the cut stop the machine, withdraw the tool, remembering the cut depth on that pass, disengage that half nuts and wind the carriage/saddle back to its approximate starting position. During this the thread indicator dial will rotate.

Move the carriage until the same marker on the thread indicator dial aligns with the datum mark, ensure the tool is beyond the end of the work piece. Wind the tool in to a depth that is the last cut setting plus the next cut depth. Engage the half nuts, these should engage readily and the thread dial indicator should not change. Start the machine and repeat the process until you have the desired cut depth.

You can cut threads in many ways and I have used the above method successfully as it is a useful starting point. If the machine has an easy reverse function then this can be used and the half nuts left engaged all of the time, the saddle is returned to its starting point by stopping and then reversing the motor until it is wound back to its starting position and the process repeated.

Hope this ramble helps a bit will look at the dial gauge table and see if I can help with that but I expect more experienced users on this forum will be posting.

Have fun

Martin

PS

It is useful to have a small recess, just smaller the root diameter of the thread, at the end point of the thread which allows the tool to finish in a free area. Without iy one can easily over run the previous cut/s with disastrous results, don't ask how I know  .

.

PPS

It looks as if you have a lead screw reversing facility on this lathe. Do Not use this to return the carriage/saddle to its original position if you are going to use the continuous engagement of the half nut method as this will destroy the registration of the lead screw to the chuck spindle.

Edited By Martin W on 31/01/2014 12:42:37

Edited By Martin W on 31/01/2014 13:13:23

Martin W.