A few months along, and I thought I'd tidy this up in case anyone's still interested….

I decided on a weight counterbalance system, as I couldn't easily see how to get a gas strut into the space, and also wasn't too keen on the possibility that it suddenly fails. Springs were interesting, but again more challenging due to the space constraints.

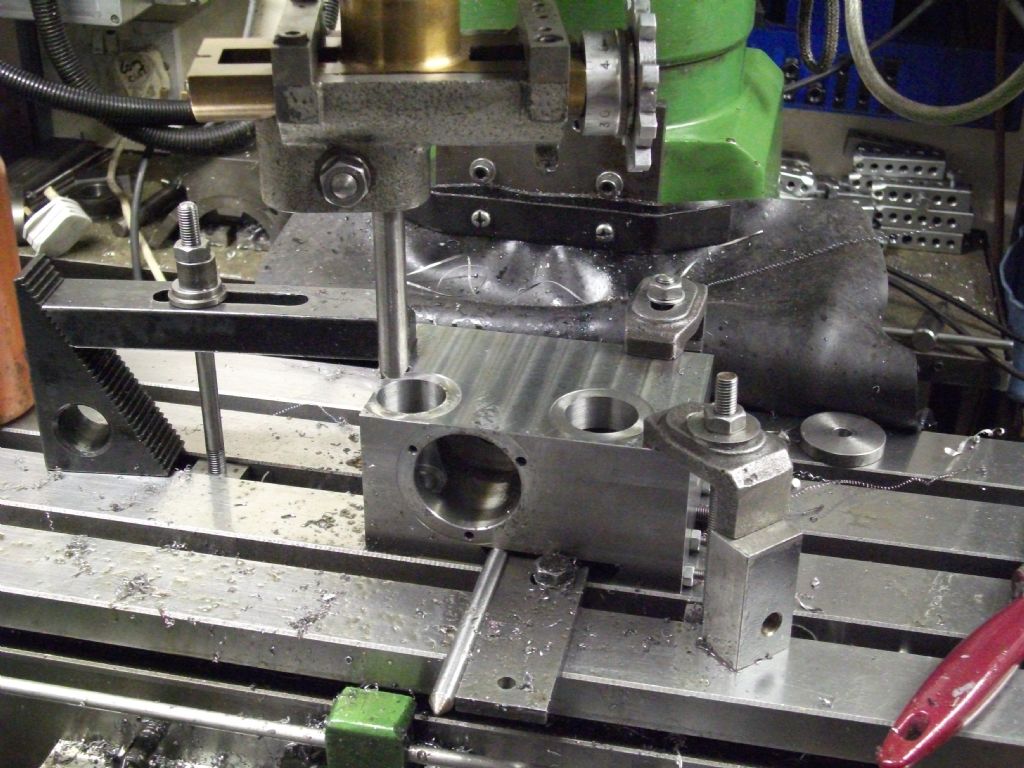

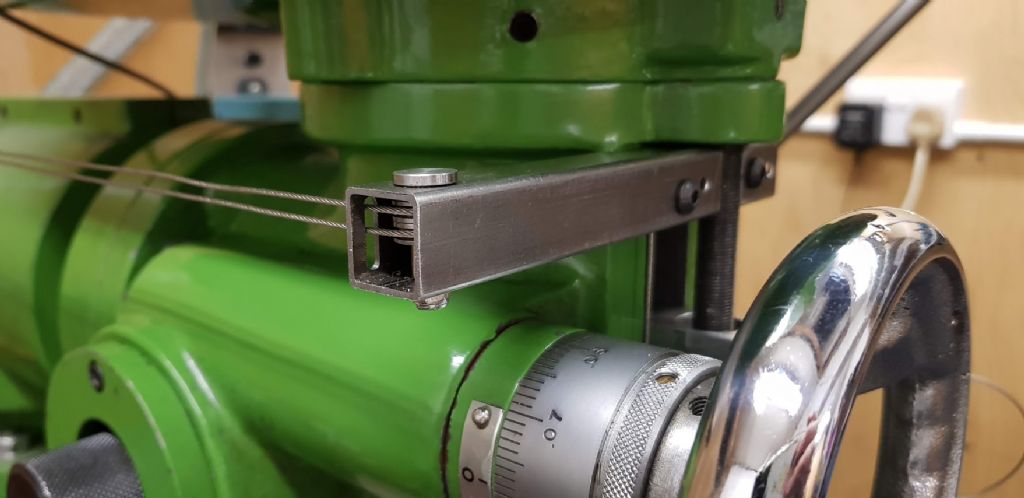

I've adapted the existing quill guide block to carry a bar that's pulled up on each side by two 1mm stainless steel ropes that are tensioned by weights at the back of the machine.

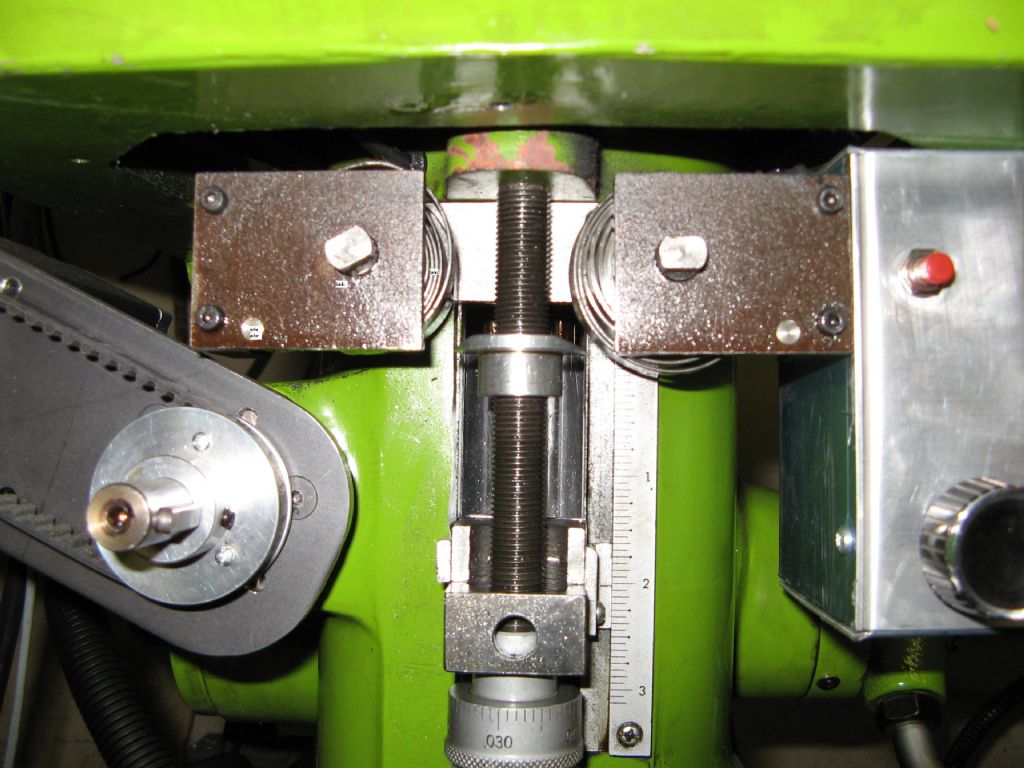

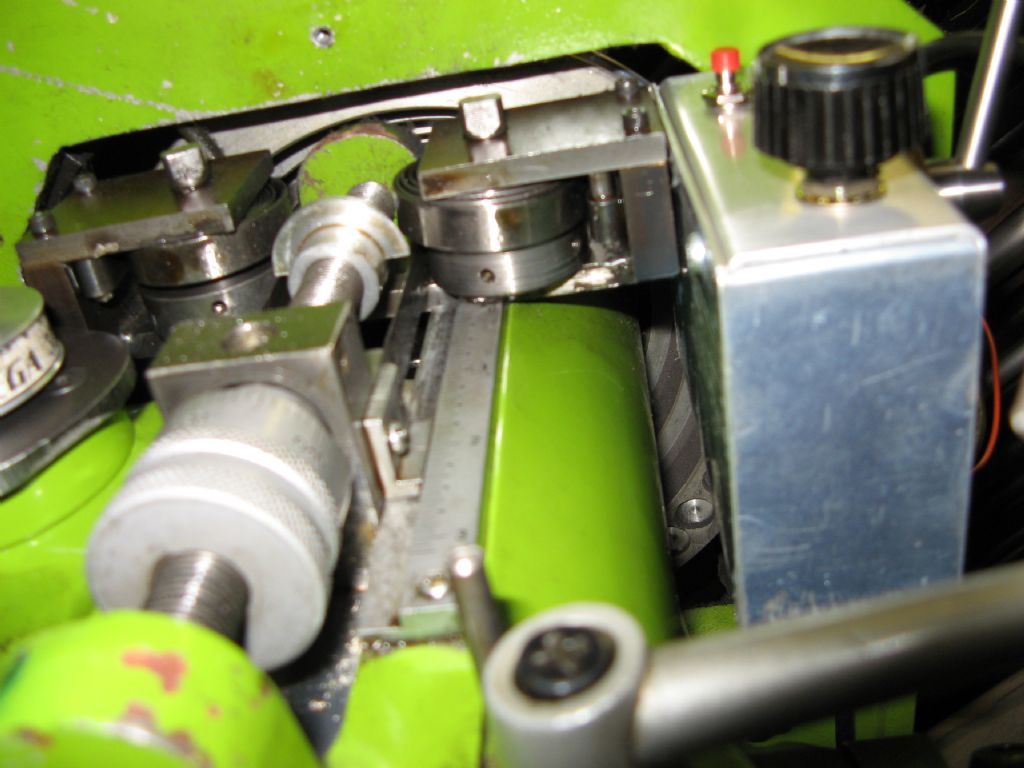

The routing of the cables to the back is dealt with by a series of pulleys in a length of steel box section:

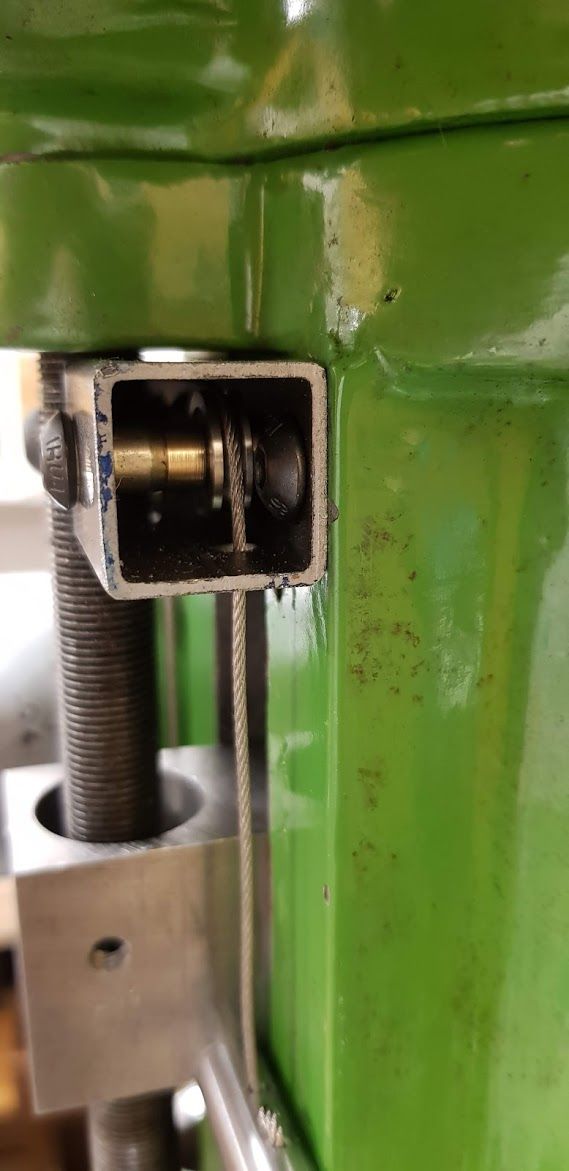

and finally there are ~8kgs of weights hanging on the end pulling on the cable. I printed a spacer bush to keep everything central and nicely symmetrical – much more material efficient than turning up something from the stock I had to hand:

(Some of the pictures were taken before the weights were attached, hence the cables are slack)

So far, it's doing really well – I'm confident that the cable strength is sufficient for the application – each cable only carries around 5kgs, and the manufacturers tell me that even with de-rating, each 1mm cable is comfortably rated at 25kgs. I've used the largest hardware (M5 mostly in pairs) that I could comfortably fit in, so in theory at least nothing is close to breaking.

Finished a week or so ago, I think it's doing the job  I might add some more weight to make the upwards force a little more positive, but the backlash and lumpiness is largely gone!

I might add some more weight to make the upwards force a little more positive, but the backlash and lumpiness is largely gone!

YouraT.

I might add some more weight to make the upwards force a little more positive, but the backlash and lumpiness is largely gone!

I might add some more weight to make the upwards force a little more positive, but the backlash and lumpiness is largely gone!