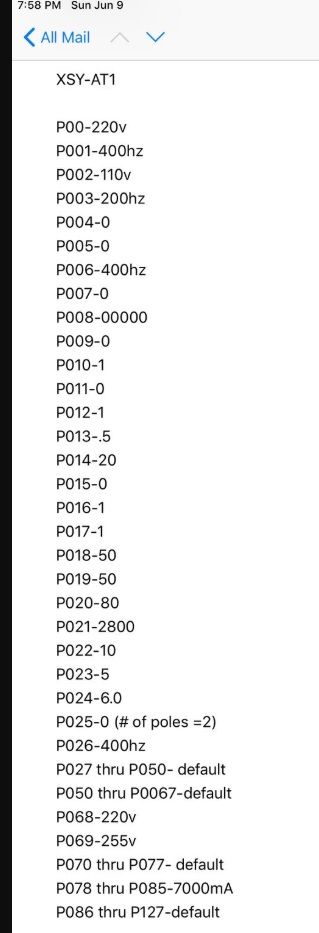

sit down, RTM and think logically….It is pretty simple, If you cant understand it seek help here. See one of my previous posts on a search for AT1 thread.

you should have a parameter P78 main current overload

set that at the calculated normal load current for your motor + 20% or what you feel comfortable with (it is expressed in mA so 6A would be entered as 6000) (the default by the way is 3000 which is why you may be experiencing trouble)

set parameter P24 to 2 seconds

make sure you have set P0 through 10 correctly (not what is the table above which is for high speed spindles)

Have regard to P12 for you application

Review the ramp times P26 P34 P42 (and others if you are using them) I have come across some units Hz/s has been a multiple of 10.

Avoid using the factory reset unless you have been through all of the parameters and written them down – sometimes the defaults are not as stated on the printed sheet and I also suspect there may be some hidden non accessible ones.

Contrary to the received blather on the net, these are excellent high quality units, let down by poor end user manuals, the connections are no more exposed than in the majority of older industrial inverters. The boxes are intended for industrial panel mounted use, but sold onto the hobby market hence the howls of outrage. The Chinese assume that the people purchasing this class of device will be smart enough to enclose the devices or carry out some other form of risk mitigation.

Edited By Martin of Wick on 21/03/2020 09:55:27

Edited By Martin of Wick on 21/03/2020 09:56:58

Edited By Martin of Wick on 21/03/2020 09:58:28

Edited By Martin of Wick on 21/03/2020 10:00:11

Edited By Martin of Wick on 21/03/2020 10:03:46

John Rutzen.