Upgrade from SC3 lathe

Upgrade from SC3 lathe

Home › Forums › Workshop Tools and Tooling › Upgrade from SC3 lathe

- This topic has 65 replies, 24 voices, and was last updated 13 February 2019 at 15:39 by

not done it yet.

-

AuthorPosts

-

14 November 2018 at 21:54 #380657

Chris Trice

Participant@christrice43267Posted by SillyOldDuffer on 14/11/2018 20:49:26:

I think you agreed entirely with Neil's logic when you said "An Emco rep was present for commissioning and performed the same verification as done at factory". I take your point that the rep found nothing wrong, but if the lathe was guaranteed rock solid why was it necessary for him to be there in Namibia at all? I'd say his role was exactly in line with "checking the gibs etc."

That assumes all customers are capable of checking a lathe and making corrections to the same degree as an Emco representative. Had he not been in attendance, the lathe would've still met the higher standards. I'd suggest he was there to check that no large impacts had occurred to the machine rather than it needing further tweaking over and above the work done at the factory. One of the outstanding points about Emco lathes that put them high on the list of quality lathes is (and I quote lathes.co.uk), "Built to a strict standard of accuracy – DIN 8606…". This is not true of cheaper lathes. Another point independent of manufacturing accuracy is the actual quality of materials used. The swiss excel at this where as there are numerous stories of poor quality grub screws and allen screws needing replacing on cheaper lathes and something I've also noticed is that a lot of my far eastern/Indian accessories I've bought are definitely more prone to rust. You do generally get what you pay for.

14 November 2018 at 22:23 #380663 Michael GilliganParticipant@michaelgilligan61133Posted by Chris Trice on 14/11/2018 21:54:49:One of the outstanding points about Emco lathes that put them high on the list of quality lathes is (and I quote lathes.co.uk), "Built to a strict standard of accuracy – DIN 8606…".

Michael GilliganParticipant@michaelgilligan61133Posted by Chris Trice on 14/11/2018 21:54:49:One of the outstanding points about Emco lathes that put them high on the list of quality lathes is (and I quote lathes.co.uk), "Built to a strict standard of accuracy – DIN 8606…"..

I have no opinion to contribute to this discussion, but I will offer one fact for consideration:

The title of DIN 8606 **LINK**

https://standards.globalspec.com/std/232647/din-8606

MichaelG.

Edited By Michael Gilligan on 14/11/2018 22:24:23

15 November 2018 at 09:15 #380712Ketan Swali

Participant@ketanswali79440Arc is happy with the sales of the SIEG SC4. We have come across limited issues, and we are hopeful that most of the customers we have supplied are happy with their purchase. We are grateful for their custom.

For those who are new to the hobby, Neil Wyatt started a beginners series on lathe work, using a SIEG SC4 in October 2017 – MEW Issue 260, which has been running in alternate issues till date. Similarly Jason Ballamy started a beginners series on milling in November 2017 – MEW Issue 261, using a SIEG SX2.7, which again is also currently running in alternate issues.

As far as ARC is concerned, these series are a long term investment into the hobby. They are helping new people to find their way through the basics, regardless of which machines they can afford, or choose to buy.

I have a great level of respect for most machine manufacturers… be they EMCO or any other, of which ever country of origin.

Ketan at ARC.

15 November 2018 at 10:24 #380724Joseph Noci 1

Participant@josephnoci1This has unfortunately gone so far of topic, but I guess that is my fault. I apologise to Ian Thompson 2 for this. I do need to respond to some points though..

DAVE:

- I think you agreed entirely with Neil's logic when you said "An Emco rep was present for commissioning and performed the same verification as done at factory". I take your point that the rep found nothing wrong, but if the lathe was guaranteed rock solid why was it necessary for him to be there in Namibia at all? I'd say his role was exactly in line with "checking the gibs etc."

No, I did NOT agree:

– He arrived with NO MEANS of setting anything – He arrived with measurement equipment – nearly 150kg worth, and a formal EMCO set of test sheets, which he filled in with each measurement test. Why are you all harping on 'that he came to set things up'??? He is from the EMCO R&D dept, and did not get his hands dirty. How better can I explain this?? The filled in sheets were then placed by him in the original file sent with the machine, with a note signed by him that the machine conforms to the original tests and specs as when it left the factory. His role was NOT to 'check gibs, etc' – his role was to validate compliance with DIN-8606!

OBVIOUSLY he came to check things! If the machine had slid across the deck on board ship and got knocked about, he would detect this and they may then have sent a team out to fix things – BUT that is not how the machine left the factory. Fixing damage was not his mandate or job – he came to PROVE the Quality Compliance!

Most of 'your' hobby lathes need setting up still, after supposedly being done at the factory – knock and drops notwithstanding.

NEIL:

- What I said was "It benefits from a little setting up but that's true of every lathe

Well, the straw man stands – I am being pedantic but it is NOT true of EVERY (small) lathe!

Some lathes are built to a standard, some pricey, but not all exhorbitant, and although the reference to 'a price of a small car' may be true, it has no place here.

And some lathes are built down to a price – take your pick.

CHRIS:

- Had he not been in attendance, the lathe would've still met the higher standards. I'd suggest he was there to check that no large impacts had occurred to the machine rather than it needing further tweaking over and above the work done at the factory. One of the outstanding points about Emco lathes that put them high on the list of quality lathes is (and I quote lathes.co.uk), "Built to a strict standard of accuracy – DIN 8606…". This is not true of cheaper lathes.

Chris sees the light! I think that says it all! Built to a standard! To what build standard is your typical Chinese lathe built? Is there a factory test sheet? If so does it cover anything more than just spindle runout ?? I would not expect a cheap Chinese machine to be made to anything like a DIN 8606 standard, but surely some industry accepted standards would benefit both supplier and client?

Seems I have rubbed the members up the wrong way, but I do believe it incorrect to lump all small lathes in the common statement..You do the manufacturer a dis-service as well as forum members – you could rather refer to the benefits of costlier machines versus the 'home setup and fettling' of cheaper machines, and let the reader make his choice.

Ian Thompson, again I apologise, and if it suits the members – mods delete my comments from Ian's post so you can all get to the business of advising Ian on the best lathe..

Joe

15 November 2018 at 14:12 #380754SillyOldDuffer

Moderator@sillyolddufferPosted by Joseph Noci 1 on 15/11/2018 10:24:32:This has unfortunately gone so far of topic, but I guess that is my fault. I apologise to Ian Thompson 2 for this. I do need to respond to some points though..

DAVE:

- I think you agreed entirely with Neil's logic when you said "An Emco rep was present for commissioning and performed the same verification as done at factory". I take your point that the rep found nothing wrong, but if the lathe was guaranteed rock solid why was it necessary for him to be there in Namibia at all? I'd say his role was exactly in line with "checking the gibs etc."

No, I did NOT agree:

– He arrived with NO MEANS of setting anything – He arrived with measurement equipment – nearly 150kg worth, and a formal EMCO set of test sheets, which he filled in with each measurement test. Why are you all harping on 'that he came to set things up'??? He is from the EMCO R&D dept, and did not get his hands dirty. How better can I explain this?? The filled in sheets were then placed by him in the original file sent with the machine, with a note signed by him that the machine conforms to the original tests and specs as when it left the factory. His role was NOT to 'check gibs, etc' – his role was to validate compliance with DIN-8606!

OBVIOUSLY he came to check things! If the machine had slid across the deck on board ship and got knocked about, he would detect this and they may then have sent a team out to fix things – BUT that is not how the machine left the factory. Fixing damage was not his mandate or job – he came to PROVE the Quality Compliance!

Most of 'your' hobby lathes need setting up still, after supposedly being done at the factory – knock and drops notwithstanding.

…

Joe

Joe, what you are describing is an Inspection, which is only part of the service provided by EMCO. Their Customer Service wording includes –

Machine installation:

Your machine is professionally assembled and commissioned by EMCO applications engineers…(My underlining.)

Granted a small lathe would have been 'professionally assembled' in the factory, but your machine also came with an installation and commissioning service. If after installation inspection had detected a problem, then commissioning would have stopped while EMCO did whatever was necessary to fix it. Commissioning is more than ticking off items from a DIN standard, it manages the possibility of failure as well. We don't know what EMCO do when a fault is found because your installation went well.

I think we all understand that an professional Western lathe will have been built and aligned to a higher standard than a Far Eastern hobby lathe and that it is more likely to be perfect 'off-the-shelf'. I hope we also understand that only god is perfect and that even the best regulated businesses cock up occasionally. (Look at NASA and Rolls Royce!)

With any new lathe I suggest the underlying process is exactly the same – on arrival all machines are inspected and any problems sorted out. The difference between a posh EMCO and my Warco is of degree not kind. Your lathe was commissioned by an expensive professional with 150kg worth of measuring equipment and is fully backed by a high-end manufacturer, I did everything myself. Your lathe was expensive, mine considerably less so!

Dave

15 November 2018 at 14:41 #380757Martin Hamilton 1

Participant@martinhamilton1I thought spending more money on a European made lathe was the way to go, this turned out to be a big mistake in my case when a bought a new Wabeco D4000 lathe. I got rid of this lathe @ a great lose just to get some money back, i had it less than 1 year a didn't do that much work on it so was like new when i sold it. This lathe was documented on this forum along with a few others that also had serious issues with the Wabeco D4000. The reason i stayed with a European machine over say a Warco was that i had had an Emco V10P for 20 years 1994 – 2016, this was a 1977 produced Emco V10P to which had served me well up until there was a failure in the headstock gears creating a mess inside the head stock. With limited parts available for the V10P & astronomic prices for the few parts that were still manufactured all be it by another company & not the original Emco factory made it not viable on this 40 year old Emco.

15 November 2018 at 15:52 #380771Joseph Noci 1

Participant@josephnoci1DAVE:

- If after installation inspection had detected a problem, then commissioning would have stopped while EMCO did whatever was necessary to fix it. Commissioning is more than ticking off items from a DIN standard, it manages the possibility of failure as well. We don't know what EMCO do when a fault is found because your installation went well.

Dave, I think that is the point – EMCO have confidence in the quality of the product and the standard to which it is built and so do NOT expect problems and therefore only sent the 'inspector', Dr C Klapf.. – From Dept Small Machines R&D – I am some 12,000km from them, and if they expect issues, they would surely send the right fellow along as well , rather than hold up the client ( me) for another week or two while sending someone out, etc.

I think we are playing word games – there was no 'commissioning' as per your definition – just verification that the lathe STILL meets spec.

We can all go in circles here forever – I am not debating as to my lathe being better than your lathe, by luck or otherwise, but trying to get it through that one cannot simply say all lathes are 'poorly' put together and need work, or that all lathes are easily knocked out of kilter and need work, etc. Again, you do the manufacturer an injustice with such public statements. Yes my lathe was expensive – that is not the point. The point is that you get what you pay for – If you pay for a specified and audited product from a recognised manufacturer that is what you get.

I understand that people are in this hobby for their own reasons and pleasure. I understand that without the cheap lathes the hobby would be crippled. I also understand that the changes in times have made all to accept the reduction in quality, service and standards and to therefore be prepared to put in more personal effort to 'make things work' . BUT that does not apply to ALL lathes! Allow the Lathe-Seeker access to other points of view and other possibilities as well. Should he ( or She) not have the where with all to purchase up, then so be it – but don't tell them there are no better choices out they if they can afford it!

MARTIN:

As I said above, Martin, I think the key lies in the product specification, ie, to what standard is it manufactured. The Wabeco series seems to be manufactured in Germany, but I would guess ( unfounded) that it is similar to a line of Italian 'bench' lathes – manufactured meaning assembled in-house, with some added value, as demanded by the import customs, ie, there has to be a percentage of in-house manufacturing to permit the company to call it 'made-in-Italy' – But these lathes do not comply with any industrial standards and carry a pedigree in name only. I am NOT saying they are poor lathes, or the like – I am saying they fall in the same category as all the other cheap small lathes. The percentage required of in-house manufacturing is small and infrastructure investment is kept low and small as well – else why would they not do it ALL in house and be proud of it??

I did not jump in with eyes closed when I purchased the 14D – I spent a long time – 7 months – digging and researching many lathes and manufacturers – the extra cost brings with it a lathe that bears up to a standard, will maintain that standard for decades, will perform well, and will hold its value till the end of my life at least!

I looked at the many Chinese lathes on offer – I went to South Africa and looked at most of the offerings in that line available there – and simply cringed. I did look at the Harrison lathes (Student 2500) – ( 600 Manufacturing agent in SA) but they were even more expensive than the 14D! Looked for Colchester and found they were now actually Harrison..

You probably realise by now I am an EMCO fan – I recently refurbished completely my V10, all leadscrews and nuts, half nuts, all fibre gears, toothed drive pully, etc – I obtained ALL the parts from EMCO in Hallein – The headstock fibre gears cost me 210 Euro..

EMCO Hallein still make in house a number of V10 parts FOR SURE – not everything, but most of what one might require in the lathes life.

It is the FB2 mill that is a problem – they still do the spindle/Quill and the head fibre gears, but nothing else – leadscrews, nuts, etc all done in Poland – I replaced my FB2 leadscrews with those 'new' Polish ones, and then refitted my old ones 2 weeks later…

Joe

Sheeshh…I'm trying hard to stop flogging…

Edited By Joseph Noci 1 on 15/11/2018 15:55:05

15 November 2018 at 18:03 #380793IRT

Participant@irtNo need to apologise Joseph – you carry on.

15 November 2018 at 20:33 #380828 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattJoe,

I am not a fan of the expression 'the exception proves the rule', but given the cost differential, your experience is like a Maclaren F1 owner telling a Mondeo driver he's wrong for saying cars don't come with a training course in their operation. Strictly, he's right but its far beyond the experience of the typical user.

Neil

15 November 2018 at 20:59 #380833Joseph Noci 1

Participant@josephnoci1Posted by Neil Wyatt on 15/11/2018 20:33:01:Joe,

I am not a fan of the expression 'the exception proves the rule', but given the cost differential, your experience is like a Maclaren F1 owner telling a Mondeo driver he's wrong for saying cars don't come with a training course in their operation. Strictly, he's right but its far beyond the experience of the typical user.

Neil

Neil, so are you saying NOT all lathes require 'setting in' , only cheap ones??

Forgive me, but I fail to grasp the applicability of your simile above..its like saying I need to be more skilled to use my expensive lathe than someone on a cheap lathe? Not sure what that has to do with the quality of either car ( or lathe..)

Maybe exception proves the rule, I don't know, but for sure generalisation does not always make a statement fact.

This has turned into some sort of silly contest, so I give up…

Joe

15 November 2018 at 22:15 #380840 Neil WyattModerator@neilwyattPosted by Joseph Noci 1 on 15/11/2018 20:59:43:Posted by Neil Wyatt on 15/11/2018 20:33:01:

Neil WyattModerator@neilwyattPosted by Joseph Noci 1 on 15/11/2018 20:59:43:Posted by Neil Wyatt on 15/11/2018 20:33:01:Joe,

I am not a fan of the expression 'the exception proves the rule', but given the cost differential, your experience is like a Maclaren F1 owner telling a Mondeo driver he's wrong for saying cars don't come with a training course in their operation. Strictly, he's right but its far beyond the experience of the typical user.

Neil

Neil, so are you saying NOT all lathes require 'setting in' , only cheap ones??

Forgive me, but I fail to grasp the applicability of your simile above..its like saying I need to be more skilled to use my expensive lathe than someone on a cheap lathe? Not sure what that has to do with the quality of either car ( or lathe..)

Maybe exception proves the rule, I don't know, but for sure generalisation does not always make a statement fact.

This has turned into some sort of silly contest, so I give up…

Joe

Actually, the most expensive lathes take several days to set up, yours must be in soem sweet spot whiere latehs only need checking, not adjustment

In the interest of global peace and harmony, I'll revise my original statement to:

"It benefits from a little setting up but that's true of almost every lathe – anyone who thinks you can plonk a hobby lathe down on a bench and expect it to give its best without checking the gibs etc. is deluding themselves."

But if you still want to criticise, please critique what I write, not an inaccurate paraphrasing of it.

Neil

15 November 2018 at 22:29 #380843 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133As I mentioned [obliquely] yesterday … The title of DIN 8606 is worthy of note, because it specifically references "Lathes of Normal Accuracy"

I am not sure how they define that term, but I suspect it will be similar to Dr Schlesinger's interpretation.

It will most likely refer to lathes suitable for general factory use … which puts them somewhere in the middle-ground between the likes of Schaublin or Hardinge and the 'Hobbyist' machines.

[i.e. perhaps more Mondeo than McLaren]

MichaelG.

16 November 2018 at 01:24 #380858Bill Pudney

Participant@billpudney37759Sorry if I'm about to introduce even more smoke into an already obscure topic. Where I used to work a 5 axis Makino mill was purchased. Cost was something over AUD$1,200,000, that's a lot of money in anyones language and it was about 15 years ago. The machine was set up at the factory in Japan, packed and delivered. On arrival a team of three or four Makino guys unpacked it, moved it to its' location and did all the installation tasks, including setting to work, making sure all the bits moved in the right order etc, this took about four or five days. Then another team of two people arrived who set the machine up, adjusted all the electronics so that the machine would achieve the VERY tight tolerances expected of it. This took another four or five days.

Then the machine was set to work, running two shifts with the third shift running unattended, "lights out", at the end of the second shift the machine was loaded so that it would run until it had finished, then switch itself off.

My point is that machines require setting up in situ, doesn't matter if they are a small benchtop manual lathe, or a big multi axis CNC mill.

cheers

Bill

16 November 2018 at 01:33 #380859Hopper

Participant@hopperPosted by Neil Wyatt on 15/11/2018 20:33:01:Joe,

I am not a fan of the expression 'the exception proves the rule', but …

And there is even more debate about the origin and original meaning of that saying than there is about the merits of Oriental vs Imperial machine tools.

16 November 2018 at 02:55 #380862thaiguzzi

Participant@thaiguzziJeez.

18k for a lathe and they send Bond out to check it's all A OK.

I'd want it to make a cup of tea in the morning for that price.

That's mint reconditioned CVA, Monarch, Hardinge territory.

16 November 2018 at 05:21 #380865Hopper

Participant@hopperI never paid that much for a new car, let alone a lathe. I'd want it to be doing a LOT more than making a cup of tea in teh morning…

16 November 2018 at 06:05 #380866Joseph Noci 1

Participant@josephnoci1Neil, THAT is all I was asking for! I really did not paraphrase but derived from your Mondeo analogy what I thought you implied…Nothing to criticise now at all!

Thank You.

Bill:

That really is smoke – A AUD$1.2M machine has no place in this debate but..if EMCO thought my lathe needed such attention, then no doubt such a team would have been sent in the first place. My eventual choice of this lathe was based on use and track record – there are a number of such lathes in educational institutions in South Africa and I went to see some while researching. My delivery experience mirrored theirs, so my lathe was not in any 'sweet spot' – simply a good machine made to a standard..

I would suggest it is obvious that the bigger the machine the more setup required – weight, length of beds, CofG etc all have far greater effect on levels, twist and such like. The floor preparation also begins to play a larger role – If people are insinuating that my lathe does not fall withing the bounds of a hobby lathe, then your mill is certainly way out!

thaiguzzi:

Actually, I made tea for Bond…

Have you really looked at Hardinge prices lately? A TFB-H with VERIFIED conformance to spec advertises typically from US$5500 to US$9500, with a few outliers. An HLV-H reconditioned but unverified from USD$8000, up to US$33000 for a verified machine. The latter topping my 14D price by a more than a third…And yet is seems you might get an acceptable one for half the price of my lathe?

A new CYCLEMATIC – the Eastern Hardinge copy – goes for $47K in the US.

I know the TFB and HLV are not the typical hobby machines, and yet many hobbyist's have one..

I think the key is that what makes the hobby your hobby is different for everyone. Circumstances may allow spending more on a machine for perhaps ( note, perhaps..) better performance, or enjoyment of the machines use, some enjoy the hobby for its use of machines, for some the machine remains a means to an end only and the less time spent on the machine the better, so money is better spent where it serves best then, etc, etc.

Don't judge and begrudge people their personal hobby choices, direction or particular financial circumstances – That way shows only disdain or jealousy!

Neil – is there a way to remove all this clap-trap from Ian's thread – maybe another thread if you do not wish to just delete the stuff not relevant to Ian's original query intent? It has contaminated Ian's thread excessively I think..

Joe

16 November 2018 at 09:11 #380881 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133For what it's worth … I have just checked Emco's page for the 14D **LINK**

https://emco.co.uk/emcomat-14-d/

and I note that it is

- Toolmaker’s precision to DIN8605

… which puts it a step up from the aforementioned DIN8606

MichaelG.

16 November 2018 at 09:30 #380884Tricky

Participant@trickyAs the encomat 14d has a maximum chuck size of 5 1/2" and a maximum faceplate also of 5 1/2" I would find it rather limiting! Not a particular useful lathe for many model engineering tasks.

Richard

16 November 2018 at 09:35 #380886 Michael GilliganParticipant@michaelgilligan61133Posted by Joseph Noci 1 on 14/11/2018 10:12:45:

Michael GilliganParticipant@michaelgilligan61133Posted by Joseph Noci 1 on 14/11/2018 10:12:45:I can post the Emco check sheets if anyone is interested, but the measurements are extensive – Runout on spindle internal, external and flat face ( all less than 0.0018mm!) Runout of test bar in chuck, including longitudinal runout from left to right ( ie, saddle moved from left to right with dial on bar) – less than 0.0022mm!, etc…They also measure the twist in the slide by attaching a DTI, and applying a set load on the slide, first at one end, then the other, and measure DTI deflection…

.

Joe,

I would be very interested to see those Emco check sheets

… if it's more convenient than posting here, could you please eMail them to me.

Thanks

MichaelG.

16 November 2018 at 11:32 #380898Martin Hamilton 1

Participant@martinhamilton1In the case of Wabeco they clearly state production in Germany on state – of – the – art – machine tools. There logo also states Made in Germany.

16 November 2018 at 11:47 #380899Joseph Noci 1

Participant@josephnoci1Tricky:

The 14D chuck size is not a maximum of 5-1/2 inch at all – the standard chuck you can opt to take with the machine is 5-1/2 inch, but thats your choice – It is not a cheesy chuck though – steel body and can run at 5000RPM – since the 14D can run at 4000RPM, thats a good thing.

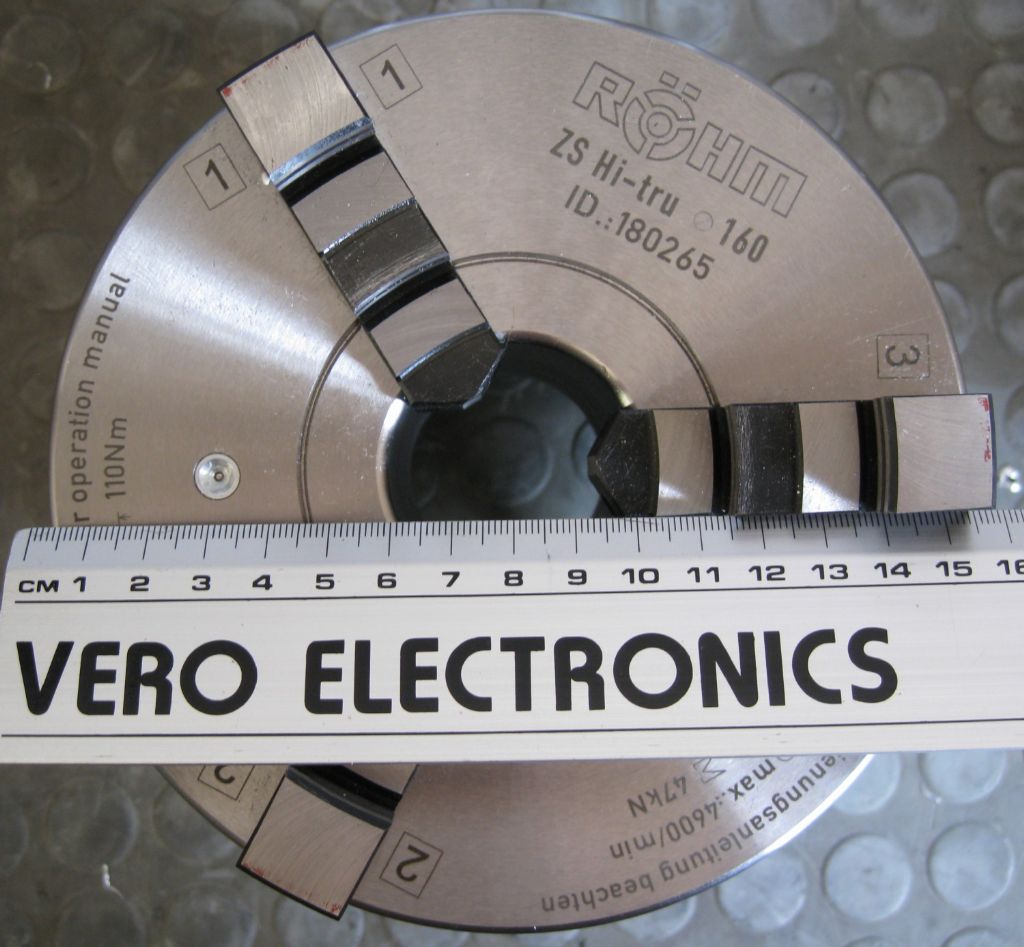

However, the choice of optional EMCO approved chucks given me and which I finally purchased are these:

A bison Steel SET-TRUE style 5C capable of 5800RPM

A ROHM 140mm steel 3jaw – 5000RPM

A ROHM 160mm Steel Set-True 3 jaw – 4600RPM

Bison 160mm Steel 4 jaw 2500RPM

And the Faceplate, or Mounting plate – 254mm, cast.

These chucks are comparable to or even bigger than the chucks supplied with, or even as options on the C4, the Warco WM280 and even the Warco WM290, which has great center height and between centres than the 14D.

The faceplate you mention of 'only' 5-1/2 inch is the precision faceplate – a cross between a 4 jaw chuck and a versatile backplate – all steel..and can run at 3000RPM.

I presume you are building big loco's or such so any hobbyist lathe would be to small for you..What folk on these forums have accomplished with lathes a 1/4 the size of mine, would amaze you…

I do small but fairly high accuracy work, so RPM is important to me, and the time saved with the machine's accuracy, instead of perpetual faffing to re-center, etc is worth all the money the machine cost.

As I said, people get their hobby kicks there own way, and my lathe helps give me mine!

Joe

edits – 'there' and 'their'…

Edited By Joseph Noci 1 on 16/11/2018 11:49:00

16 November 2018 at 13:54 #380913 Neil WyattModerator@neilwyatt16 November 2018 at 14:05 #380914

Neil WyattModerator@neilwyatt16 November 2018 at 14:05 #380914 JasonBModerator@jasonb

JasonBModerator@jasonbI think it is just the wording on Emco's site that may put people off when they see the small sizes listed as you could easily think it won't swing larger.

100mm 3-jaw is about right on a 200mm swing machine coupled with a 150-160 lightweight 4-jaw and is what I used to run on my Emcomat 8.6. Now I have the larger WM280 which is the same size as Joseph's I have 125mm 3-jaw and 5C, a lightweight/slim 160 4-jaw and 254mm faceplate.

The one reason you may want to go up a chuck size is to make the most of a big bore spindle as the larger chuck will also have a larger through hole.

J

PS you would have thought they would throw in a fixed steady at that price

Edited By JasonB on 16/11/2018 14:07:18

16 November 2018 at 14:56 #380917Joseph Noci 1

Participant@josephnoci1Jason:

I don't think EMCO throws anything in for nothing…!

No steady, fixed or travelling, although I did purchase both, if only for completeness. I have both for the Maximat V10, and have only ever used the fixed steady once in nearly 40 years!

The sizes shown in the 14D brochure are the standard ones supplied with the machine – They will retain those and offset the cost against other approved choices.

All those chucks were a significant part of the 18K EURO – nearly 7K. So the Lathe price is actually a lot less..

But a very neat gadget I did purchase is the ER collet tailstock turret – I use that so very regularly that I wonder how I did without it before. It does take some care though – not snagging your hand or side of the head on that porcupine to the left of you…

Joe

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Workshop Tools and Tooling › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

3 phase converter

Started by:

glynboy12 in: Beginners questions

- 3

- 10

-

13 August 2025 at 14:25

Robert Atkinson 2

Robert Atkinson 2

-

How does this power pack work?

Started by:

ell81 in: Beginners questions

- 12

- 17

-

13 August 2025 at 14:24

ell81

-

3 phase supply (again)

1

2

Started by:

colin hamilton in: General Questions

- 14

- 38

-

13 August 2025 at 14:09

Robert Atkinson 2

Robert Atkinson 2

-

MYFORD SUPER 7 CRATE

Started by:

Jeff Barnett in: Help and Assistance! (Offered or Wanted)

- 7

- 8

-

13 August 2025 at 13:30

noel shelley

-

What Did You Do Today 2025

1

2

…

8

9

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 35

- 220

-

13 August 2025 at 13:23

bernard towers

-

External Thread Cutting

Started by:

peak4

in: The Tea Room

peak4

in: The Tea Room

- 3

- 3

-

13 August 2025 at 13:16

Michael Gilligan

Michael Gilligan

-

Maxitrak Atkinson Lorry

Started by:

Richard Simpson

in: Miscellaneous models

Richard Simpson

in: Miscellaneous models

- 4

- 9

-

13 August 2025 at 12:15

Richard Simpson

Richard Simpson

-

Where to buy Model Steam Engines

Started by:

David Deaville in: General Questions

- 7

- 7

-

13 August 2025 at 11:31

JA

JA

-

Backplate

Started by:

Steve355 in: General Questions

- 9

- 12

-

13 August 2025 at 11:19

cogdobbler

cogdobbler

-

Hex Wrench

Started by:

Vic

in: Workshop Tools and Tooling

Vic

in: Workshop Tools and Tooling

- 14

- 25

-

13 August 2025 at 10:43

Nicholas Farr

Nicholas Farr

-

QCTP for chester lathe

Started by:

Chris12 in: Beginners questions

- 8

- 17

-

13 August 2025 at 09:50

dk0

-

Stuart Restoration

1

2

Started by:

Richard Simpson

in: Stationary engines

Richard Simpson

in: Stationary engines

- 20

- 48

-

12 August 2025 at 22:39

Howard Lewis

-

What are these?

Started by:

ell81 in: Beginners questions

- 6

- 7

-

12 August 2025 at 22:07

Howard Lewis

-

Cheap DRO

Started by:

Steve355 in: General Questions

- 10

- 16

-

12 August 2025 at 22:01

dk0

-

Things you’d forgotten you had – Volstro Head

Started by:

Peter Neill 1 in: Workshop Tools and Tooling

- 5

- 7

-

12 August 2025 at 21:03

Pete

-

smokeless cutting oil

1

2

Started by:

Chris12 in: General Questions

- 16

- 31

-

12 August 2025 at 21:02

Chris12

-

Thermal imaging

Started by:

John MC in: The Tea Room

- 5

- 12

-

12 August 2025 at 15:07

Robert Atkinson 2

Robert Atkinson 2

-

Who’s to be trusted ?

1

2

Started by:

Michael Gilligan

in: Electronics in the Workshop

Michael Gilligan

in: Electronics in the Workshop

- 16

- 27

-

12 August 2025 at 13:49

Michael Gilligan

Michael Gilligan

-

How to annotate a group photo

Started by:

Greensands in: The Tea Room

- 9

- 10

-

12 August 2025 at 13:20

blowlamp

-

EW Stringer Lathe Spindle Thread

Started by:

James A in: Workshop Tools and Tooling

- 8

- 23

-

12 August 2025 at 12:57

BB12

-

TurboCAD Snaps and Dimensioning?

1

2

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 9

- 37

-

12 August 2025 at 08:55

Zephyrin

-

Rotary table Chuck mounting.

Started by:

John Gray 7 in: General Questions

- 9

- 11

-

11 August 2025 at 18:43

old mart

-

Mounting chuck directly to rotary table.

Started by:

old mart in: Hints And Tips for model engineers

- 5

- 9

-

11 August 2025 at 18:14

old mart

-

Mini selfcentering stady rest

Started by:

dk0 in: Workshop Tools and Tooling

- 8

- 22

-

11 August 2025 at 16:49

dk0

-

Odd RAF Specialist Tool?

Started by:

Martin King 2 in: Help and Assistance! (Offered or Wanted)

- 13

- 20

-

11 August 2025 at 11:24

Robert Atkinson 2

Robert Atkinson 2

-

3 phase converter

-