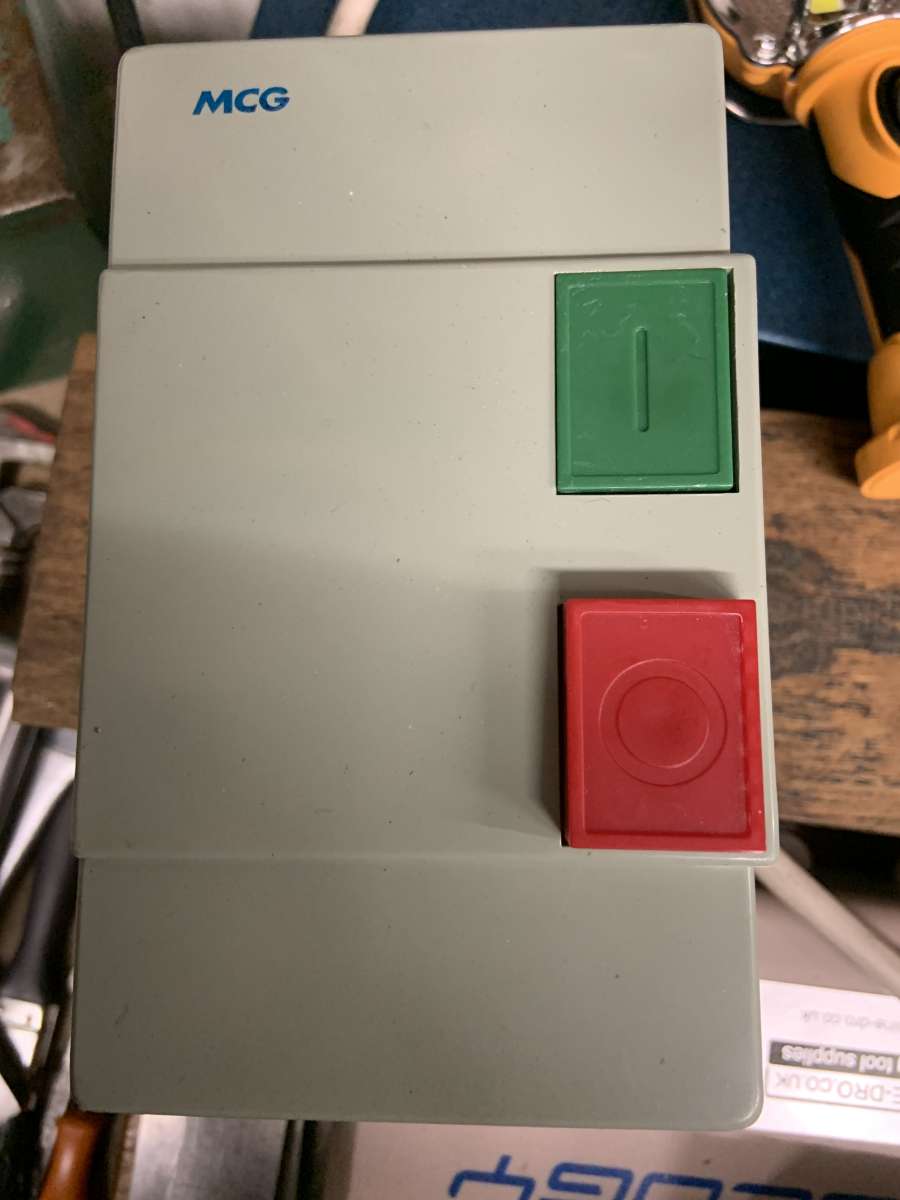

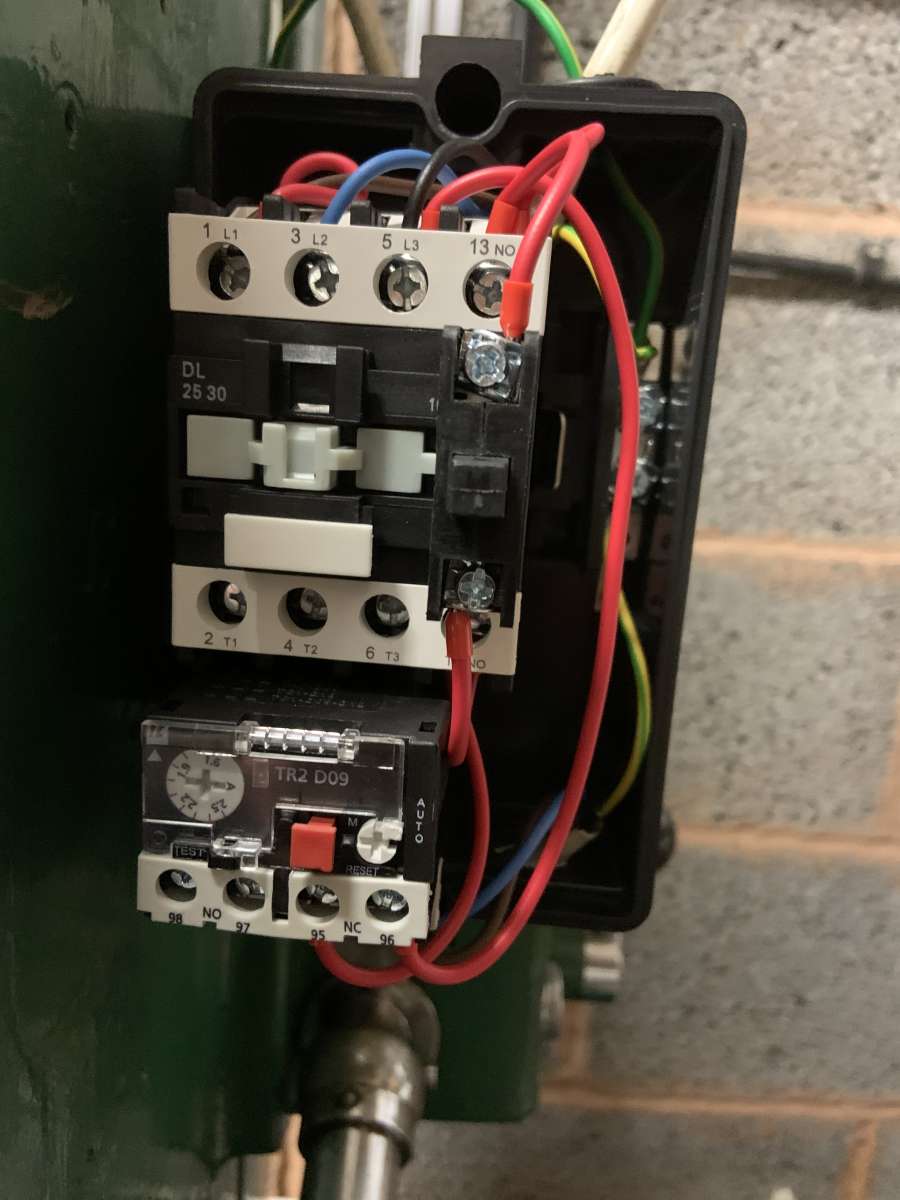

I don’t like the news that starters are burning out. What make and model were they? Their purpose is to protect the motor against high current during the start-up phase, and I would expect the thermal cut-outs to operate without drama if the problem were simple.

First thing to check is that the mill turns freely. If a bearing is binding, or some other drive train fault is loading the machine heavily before it starts, then maybe the motor is already horribly overloaded before being asked to cut metal. Also, how hard was the mill being driven, and for how long? As a 1HP mill isn’t a metal muncher, the operator has to drive it with TLC, and a learner might not recognise a difficult material or blunt cutter etc etc.

When the motor was running, did it turning smoothly, without odd noises or getting hot?

I fear the motor has one or more shorted windings, and this is overloading the electrics and doing nasty things to the converter. I’m not sure what happens to a converter when one phase draws excess current. Maybe that phase’s thermal cut-out operates leaving the motor running on only two phases, which is bad news. I imagine a static converter would misbehave badly with an unbalanced load, and so would a rotary, depending on which phase had failed.

Chris’s suggestion that the resistance of the 3 windings be measured is a good one. With the motor disconnected, all three windings should have the same resistance. A DC resistance check may not be conclusive though, because the short might be quite small, only causing havoc when AC is applied.

The electrician may be on a steep learning curve himself. Not many domestic sparkies have to debug 3-phase motors, and not many industrial sparkies run 3-phase motors off static or rotary converters!

Dave

Paul Radford.