Threading feed table & calculators, do not match.

Threading feed table & calculators, do not match.

- This topic has 40 replies, 14 voices, and was last updated 11 July 2016 at 19:30 by

Dave Smith the 16th.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- quality 3 and 4 jaw chucks

- Boiler hydraulic test 4 hours

- Model Turbines

- Pragotron Slave Clock

- Miniature parts maker in Leicester?

- Pratt Bernard Grip true issues

- Will iron rivets expand to fill oversized hole?

- UK Steel Supplier? 125 x 125 x 50 BMS

- Fobco or a Clarke CMD 1225 milling capabilities? or other recommendations?

- DELL / StarTech [mechanical incompatibilty]

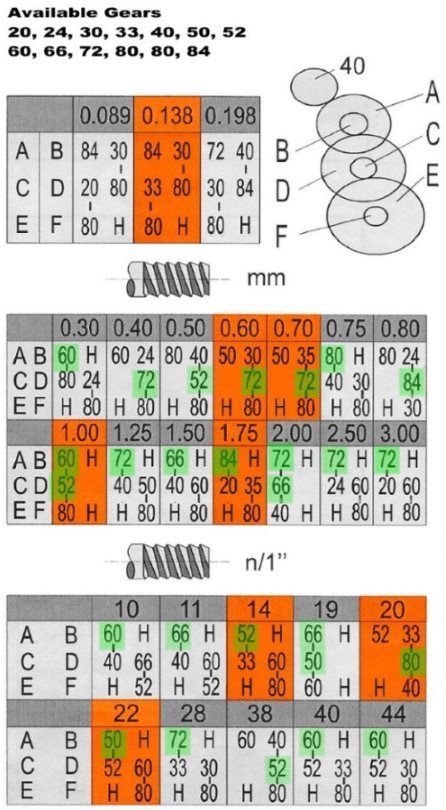

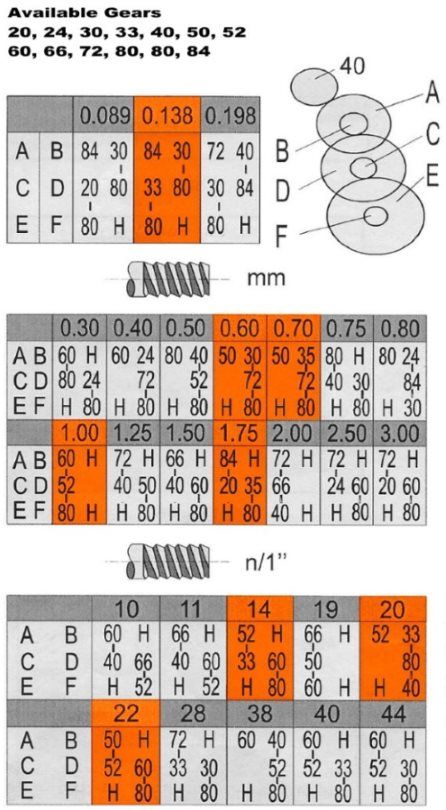

While I'm at it you seem to have a 2mm pitch lead screw. When there is no compound gear in the train the 40T on the spindle is effectively driving the gear on the lead screw and any gears can be used in between.

While I'm at it you seem to have a 2mm pitch lead screw. When there is no compound gear in the train the 40T on the spindle is effectively driving the gear on the lead screw and any gears can be used in between.