To minimise loading the bearings, make an extractor for the Drawbar.

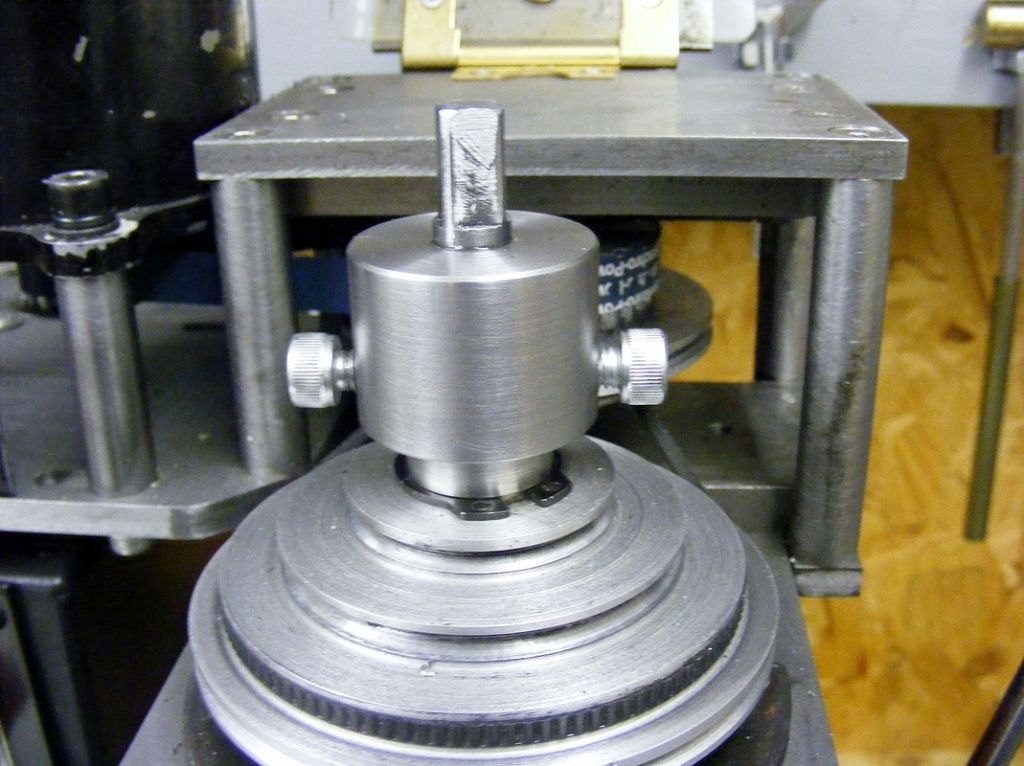

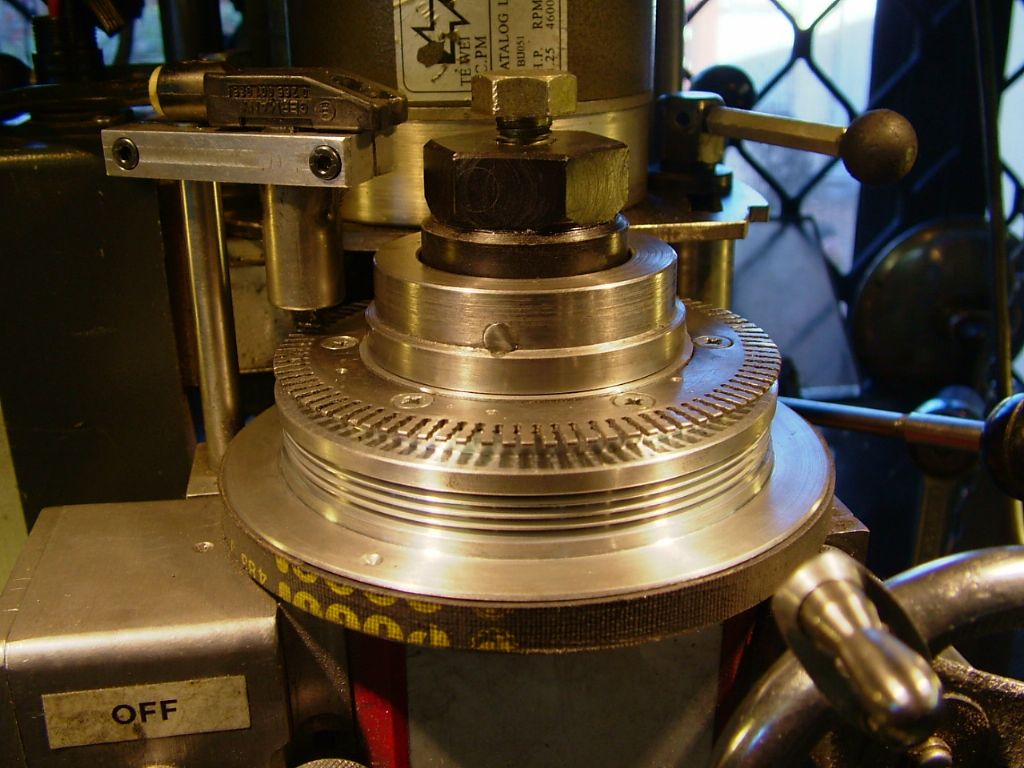

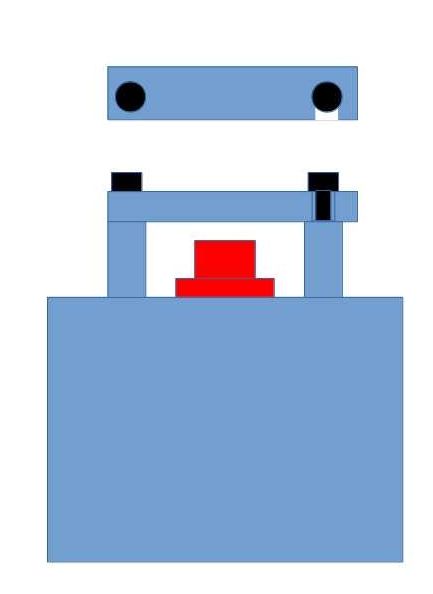

My method was to remove the pulley retaining nut, (On the RF25 Mill/Drill, it is a Left Hand Thread) and turn back the hexagon for a length of 3mm. I then made up a 3mm plate with a central hole that was a running fit on the new plain diameter of the nut, and with two symetrically placed tappings, towards the outer edge. Then made up a similar plate, but with with two clearance holes to match the tappings in the first plate, but with a central tapping. (Threads were 1/4 BSF in my case, but M6 nowadays, I would expect).

Dimensions are not critical, as long as the captive plate provides a large enough area bearing on the underside of the nut, but do not take too much off outside the thread. Midway between the hexagon and the thread O D should be O K.

Place the plate with the large hole over the shaft, and refit the nut with the plain diameter locating in the hole in the plate, and tighten the nut to retain the pulley.

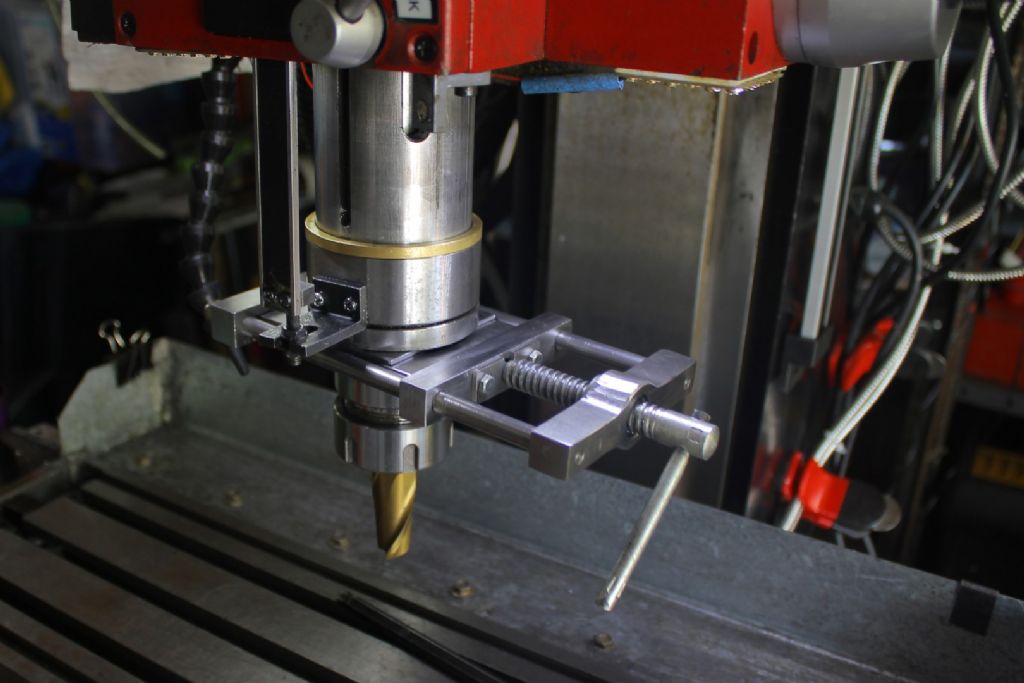

When you want to release the Morse (or other) taper, Slacken the Drawbar by about half a turn. Secure the other plate with two setscrews (With nuts below the upper plate to make the setscrews captive) through the clearance holes into the tappings on the captive plate, (equally), and run a setscrew through the central tapping, and tighten it to apply load to the Drawbar. This should break the taper, without loading the bearings. It it doesn't, an additional light tap with a mallet should produce the desired result.

If 0.5D thread engagement for M6 worries you, either weld nuts below the plate, or if a glutton for punishment, use loose full nuts below the plate instead of tappings.

Once the taper is released remove the two outer setscrews and the upper plate, and put aside, ready for use, next time.

Howard

Vic.

Vic.

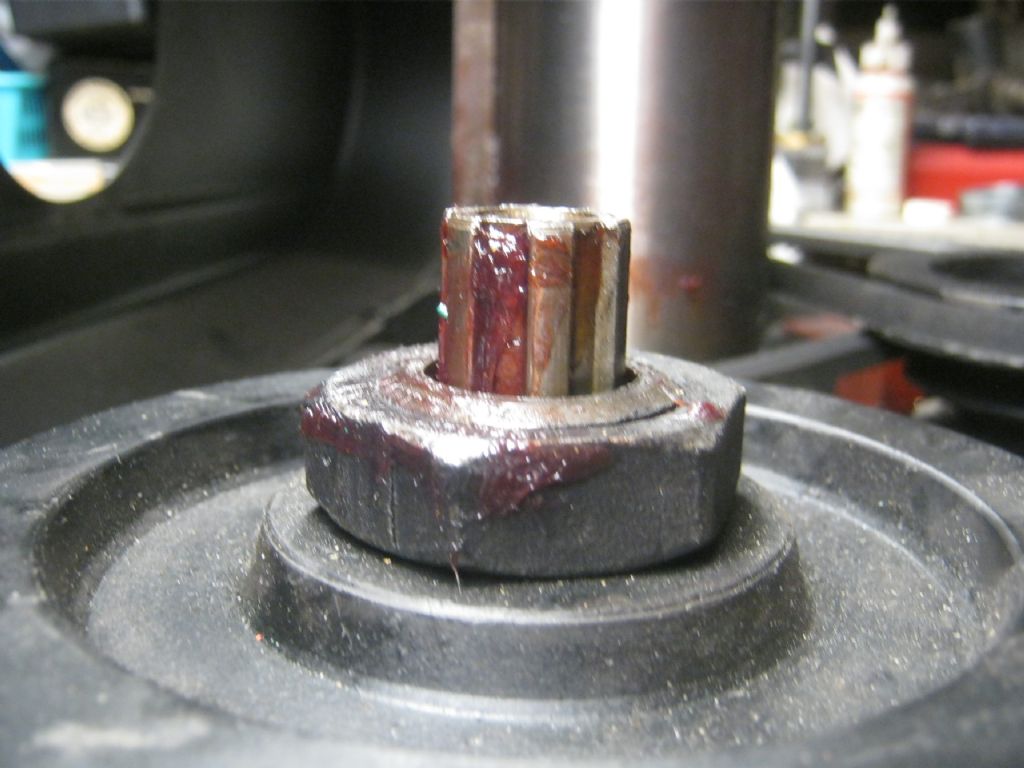

Yes, i has allready learned out it's not neccesary with much torque to keep MT 3 on place..

Yes, i has allready learned out it's not neccesary with much torque to keep MT 3 on place..