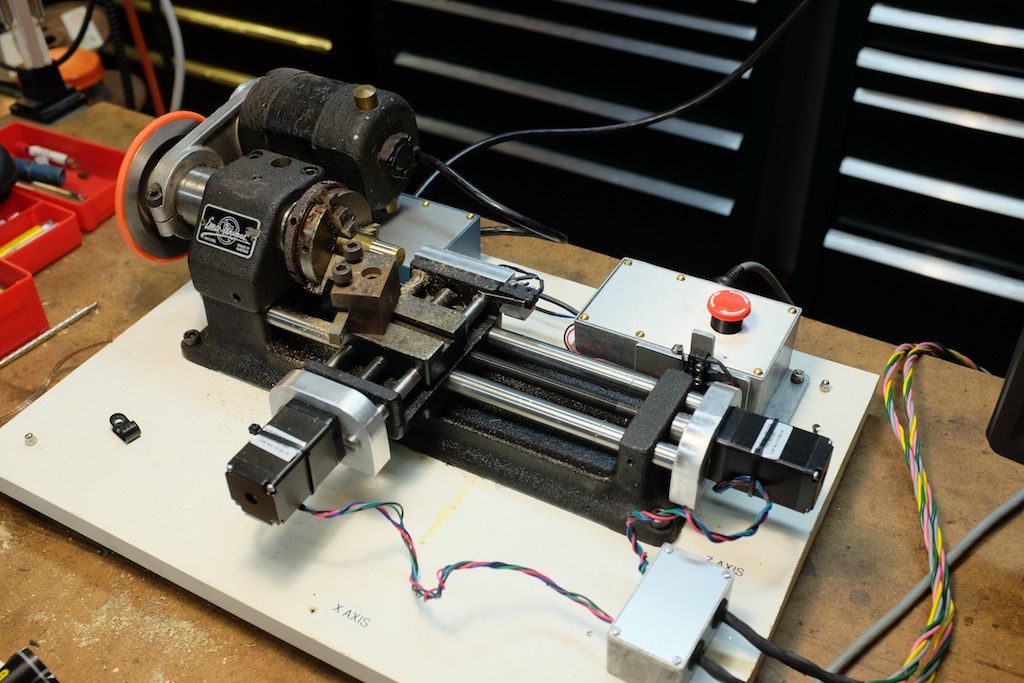

Thanks to all for your interest, in defence of my design which was started some 7 or 8 years ago there were not many designs aimed at the particular problem of providing an electronic gearbox to replace change wheels on a lathe at that time.

I have to tell you that in no way was I expecting to publish an article on this, and it was something that I required for my own use exclusively. My knowledge of programming Arduino's at the time was zero, I specifically had to learn about it for this project.

I certainly did not want a full CNC system which the Electronic Leadscrew Group were producing, I needed a simple effective and cheap as possible solution to the problem otherwise it would have been much easier to purchase a lathe with everything ready and working.

I can understand why the idea of syncing two boards seems to be like 'cutting the lawn with scissors!' however at the time the main concerns I had about using 2 separate boards were that, yes, they might drift…especially as they had resonators fitted and were of Chinese origin, to be honest I was not over confident about their quality.

I decided to to do a few simple experiments to ascertain how much they did actually drift, however with no proper measuring equipment the only recourse of action was to program each board with the Blink program set to 500ms periods and see if they stayed in sychronisation, it confirmed my suspicions, after perhaps a minute or so I definitely detected a change in the blinking phase.

I was also concerned as to whether variations in supply voltage and temperature variations would affect these things, and I was also aware that there would be a difference in frequency of the two oscillators and that perhaps as one increased in frequency the other might be going down.

After much deliberation and not wanting the onerous task of wiring up for one resonator I had to make a decision, would I take the risk of perhaps ruining a piece of turned work I had spent much time and effort on for the sake of a few minutes of re-wiring? or just get on with it and at least be sure that if there were any more unknown gremlins lurking in the shadows then this would lay them to rest.

One member has suggested using a computer to derive the signals for the drivers, which is ok but then you need a monitor and a keyboard as well next to your lathe, yes you could use a laptop, which nowadays are much cheaper than when I started, in fact many things have changed over the time since I started building it and I would have perhaps designed differently in light of hindsight.

I hope this explains some the reasons for the design, and I hope it shows that an old lathe can be given a new life with a little bit of effort which has become easier since the introduction of new boards and a better understanding of using the Arduino's

All the best for Christmas….. Bob.

Michael Gilligan.

Michael Gilligan.