Hi All,

So I am in the process of finishing a Stephenson's reversing gear set (from Stuart) for my D10.

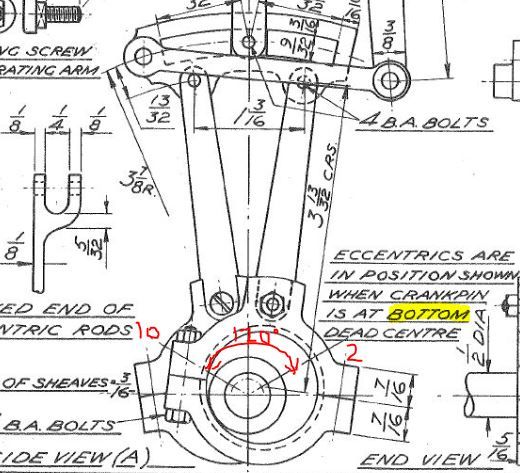

Generally speaking I thinking my machining is pretty accurate and I have the eccentrics pinned at 120 degrees apart per the instruction. I did this by marking the first eccentric out using trigonometry, drilling, then placing this against the second eccentric (flipped over)to drill that one.

Anyway – when it comes to setting up the timing, I have adjusted the eccentric strap to expansion link rods such that I get equal travel in both the forward and reverse settings…..next I have set the eccentrics such that the valve timing is correct when say in the forward direction – that is – just before TDC, the top port starts to open to cushion the piston travel and likewise at BDC it is also correct (ish/valve may need filing slightly to get it totally accurate)…..anyway, now when I switch to reverse and turn the crank over in the opposite direction, the timing looks to be way off….like about 60-70 degrees off! Why?

I can only conclude that the eccentrics are not set correctly. I can understand a couple of degrees in accuracy, but so much?!?! I have seen the principle of sliding eccentrics such that you can fine tune, but is this practical on a D10 given the size? Am I going to have to make new eccentrics as my existing ones are nicely pinned together with red Loctite. Maybe heat can separate them?

Any other advice?

Thanks

Matt

JasonB.

JasonB.