Posted by HOWARDT on 12/05/2018 13:51:02:

A pin chuck (I think that’s what is called) is good for small diameters, closes to zero. They are on a small diameter. shaft

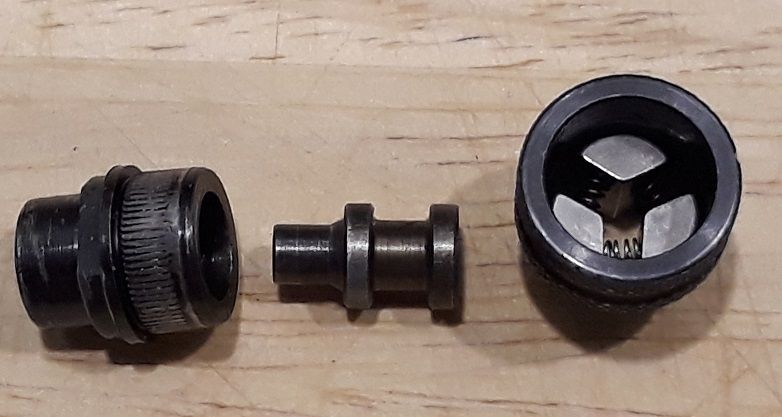

That is correct. Effective I have made it a pin chuck when it uses the full range of collets from Dremel and the other rotary tool people that have copied , making collets that cover from the very small to the 1/8 diameter. One of the things i did discover, was that the new collet nuts were not as well made as the older one that I am now using. The font taper is not that concentric to the threads on the 2 new ones that I brought. The same goes for the repaired drill chuck. The 1st few times I used it, it ran to look at true. Then when I tried it with a different sized (1mm drill) it was wobbly. I rotated the jaws inside body, so as it closed the jaws moved with the outer body, and found a position where it ran true to look at. What a pain. So it seems there is a concentricity issue in the parts of the mini drill chuck itself. My next mission, will be to make a copy of the parts , and just use the jaws and springs, to make a mini drill chuck that runs true over the range. I don't need any bigger than 1/8 inch from it anyway. I will have the keyed chuck arriving in a few weeks time anyway. But do like the convenience of the keyless chuck. My main use is for small holes under 1mm and allows to feel what is happening. The quill on the ZX45 mill just does not have the feel needed for small drills for me anyway.

I deliberately did not make it with a return spring, as I wanted to have the longest travel possible with the height and still using the 13mm capacity drill chuck. I could make a longer one, with a spring return, but then that would mean using a MT4 collet, or using the ER32 or ER40 collet chuck to hold the adaptor.

Neil

Marcus Bowman.