I've dithered around this one as well. Like Jed my measuring kit is only good to 0.01mm at very best; usually I work in the 0.02mm region, better only if it really matters. Is it worth me owning a Gauge Set, and if so what sort?

Fairly easy to dismiss are the Grade 0 and Grade 1 sets. Expensive and only worth the money if you are a tool-room or metrologist. In this range of accuracy, special care, calibration certificates, clean-rooms and temperature control may be essential. One thing to own a box of Grade 0 gauges, quite another to to use it properly!

Another type I can dismiss are the fancy Grade 2 sets made of ceramic or carbide. These are made to resist wear and tear in busy environments where they are frequently used. I'm not busy.

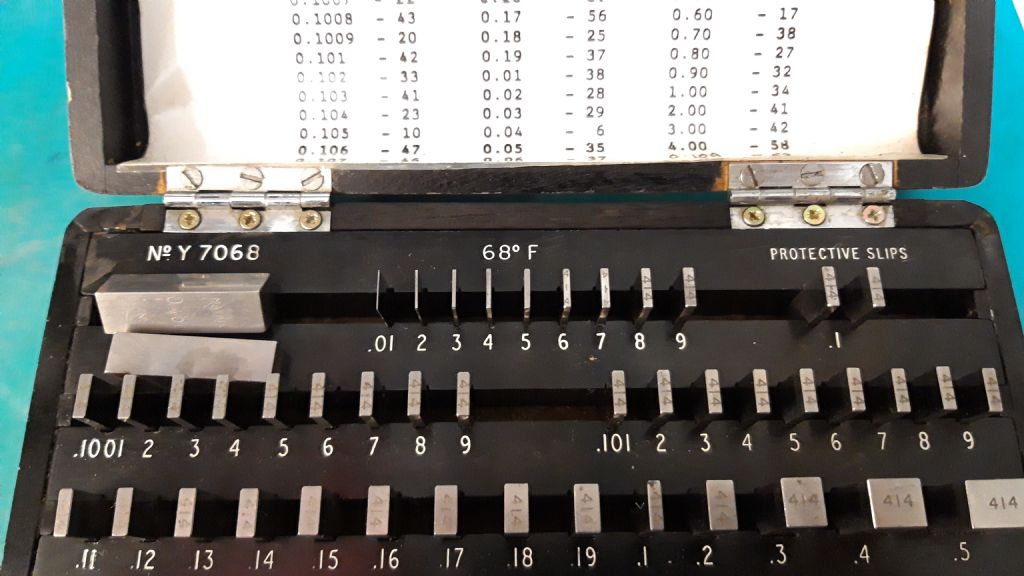

A new set has the advantage of guaranteed accuracy. The slips aren't worn, scratched, dirty or dinged on their edges. This means any combination of slips can be stacked together ( "wrung" ), and still be accurate. Rule of thumb for calibrating a measuring tool like a micrometer is that the standard should be about 10x more accurate than the micrometer. The graduations on a metric micrometer are typically 0.01mm apart and it's possible to eyeball half that, or even thirds. But if the micrometer is slightly 'out' at 0.01mm already (it probably is, because both instrument and operator are unreliable!), these estimates are unlikely to be trustworthy. By testing the micrometer against a gauge stack in good nick, it's possible to confirm whether or not the micrometer/operator combo are consistent, and more usefully suggest what corrections are needed. Beware, a decent set of gauge blocks may tell you all your tools are carp and/or that you're an incompetent operator! Good news for me, the number of times I've needed to work to this level of accuracy is zero!

You mention using the gauges for setting up on the mill. Perfectly reasonable if that means confirming the accuracy of a set-up, not a good idea if the slips are used for work holding. The latter is abuse sufficient to undermine the accuracy of the set. Much better to use parallels, blocks or whatever, and check them for accuracy by comparison with the gauges. The number of times I've needed to work to a level of accuracy requiring gauge blocks with my milling machine is zero! I'm a hobbyist, not a Swiss Watchmaker.

For me a brand-new set of gauge blocks is over-kill. I'm tempted by a second-hand set though. Most likely, these are available because they failed calibration because one or more blocks in the set is damaged. When 10x resolution is essential, they get dumped immediately by the professionals. But for ordinary workshop use 5x accuracy is often adequate, and 2x would meet my rough needs. This is an eyes wide open decision though. If you genuinely need gauge block accuracy, don't arse about buying unknown second-hand – buy new or insist on an up-to-date certificate! But if the goal is to cross-check relatively low importance workshop measurements, to be more confident in the 0.01mm region, then why not.

If someone gave me a new gauge set for xmas I'd be delighted. It's the sort of present I'd enjoy, but can't justify buying myself! I'd use them to find out the error margins of all my Digital Calipers and Micrometer. To do this properly the full range of the instrument has to be checked. There's no guarantee that an micrometer good to 0.01mm at 5mm will still be true at 20mm. Might get expensive, because none of my instruments are high-end. After finding out just how iffy they really are I might have to replace the whole lot with Mitutoyos or better!

Dave

Edit poxy smiley!

Edited By SillyOldDuffer on 14/12/2019 10:17:52

Robert Atkinson 2.

Robert Atkinson 2.