I had another clean- there were some traces of dried grease left which I thought were out of the way – they may have been doing a little. I gave it a hard rub with a dry cloth which appeared to polish the Al.

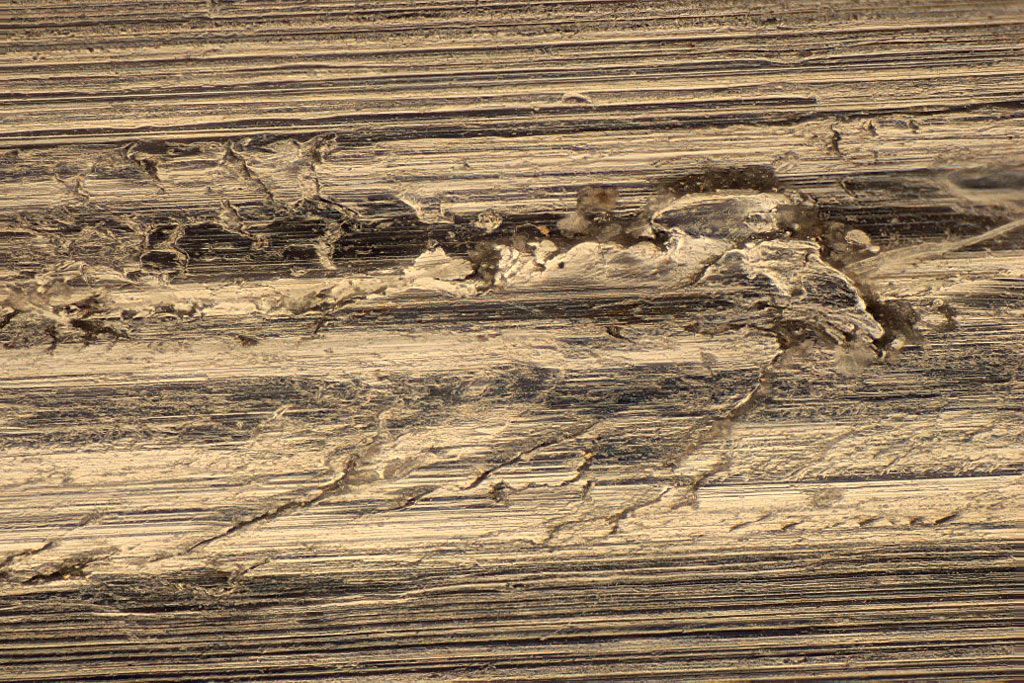

There are the two carriages running on the dovetail. One is tight, the other is tighter. The tighter one started to bind again. I could just about see smething so I took a picture of it:

Ignore the colour, it's "grey". The colour balance is off, but I found when I made it grey the relief didn't show up as well.

Frame width is about 1mm. Focus depth is about 60µm. How galling, eh?

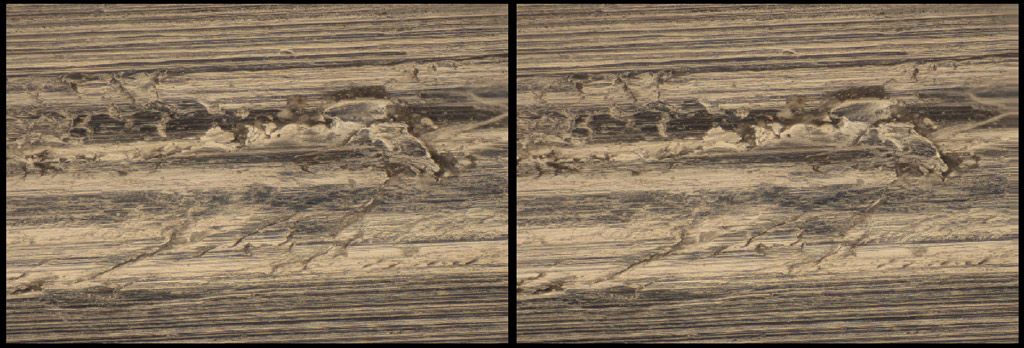

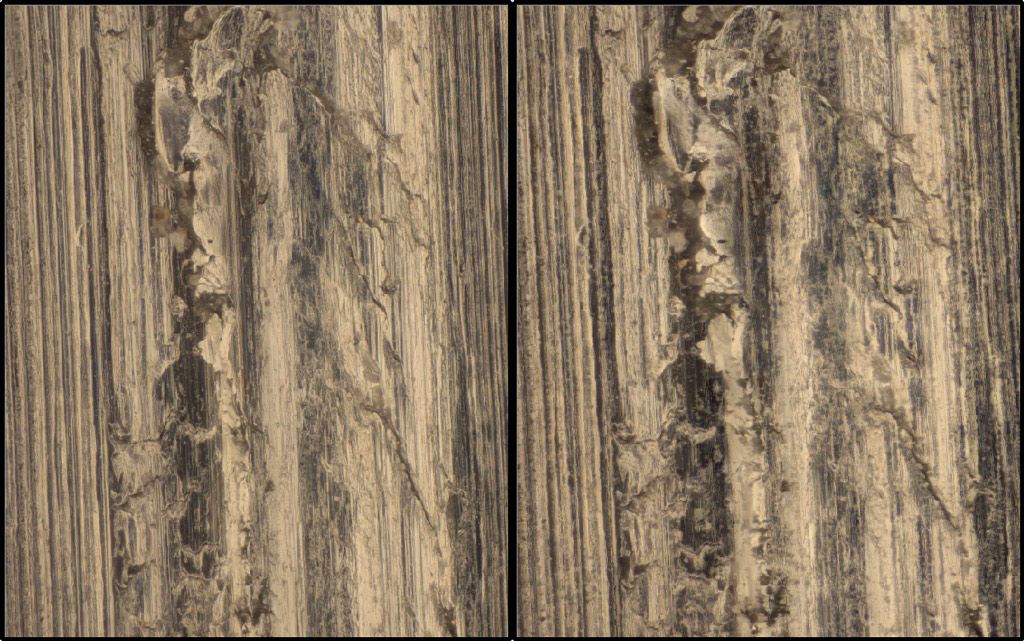

If you can cross your eyes a bit, try these:

( you have to make it so you can "see" three boxes, with the middle one being one from each eye.)

I expect most WON't see those as 3D – it's not hard but it takes practice:

If you download this (~4MB) it should help

**LINK**

Edited By Chris R 1 on 06/02/2019 01:15:46

Simon Williams 3.