As long as the top rake is satisfactory, (Mostly, I work without it, certainly on the parting tool in the rear toolpost ) the only faces that need a regrind are the front and side clearances.

As soon as the sharp edge is regained, the regrinding process is complete. Further grinding just removes HSS that could have been used productively.

For a lot of work, I use a Tangential Turning Tool (Home made for 1/8 and 5/16, bought for 1/4 )

There is only one face to grind, and the jig sets the angles, so all it needs is a light skim to clean up.

(It has taken about 4 years to wear the short, 1/4" square toolbit supplied with the Eccentric Engineering Diamond tool, to the point where it needs replacement, if that is any indication )

Quite often a very light touch with a stone or diamond file will suffice.

Unless the shape is being changed, or it is chipped, very little,regrinding is needed to restore the edge.

When it eventually is worn so much that it is no longer strong enough for the task, then is the time to grind the end back to flat, and start again setting the clearance angles.

When the toolbit becomes too small to hold, then is the time for replacement.

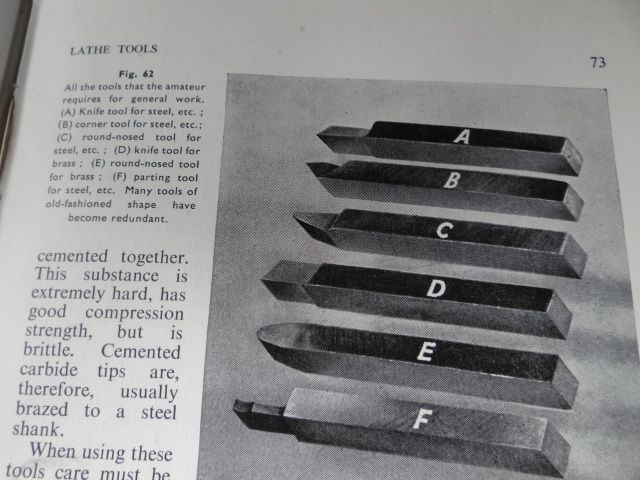

For most purposes, what do you need? The list covers almost every possibility that you will ever need.

RH Knife tool

LH Knife tool For the rare occasions when needed..

Possibly finishing versions of the above with a small radius on the cutting edge. make sure that the radius is all the way down the edge, so that it cuts at the "point" rather than rubs below it.

Parting tool

55 Degree External screwcutting

60 degree external screwcutting

55 degree internal screwcutting

60 degree internal screwcutting

A tool to fit into a Boring bar.

Small boring bar.

Form tools for chamfering or radiusing; as and when you need them

If you were to make up all of these, some will see very little or no use.

In Front and Rear 4 way toolposts, my lathe carries

FRONT POST: Rougher, Tangential, and Boring bar; and

REAR POST Front Chamfer, Parting, and Rear Chamfer

For Screwcutting, Knurling, or Ball Turning, one of the Front tools is removed, temporarily, to make a space for it..

So almost AL:L my work is done by, at most, nine tools (For a half round thread form, I did use a type of Tangential tool using a 1/8 round toolbit. But that was a one off!

And I try to avoid internal screwcutting, if possible, or another two might be needed., to cover all eventualities.

Howard

Howard Lewis.