Posted by Ron Laden on 24/11/2020 10:46:13:

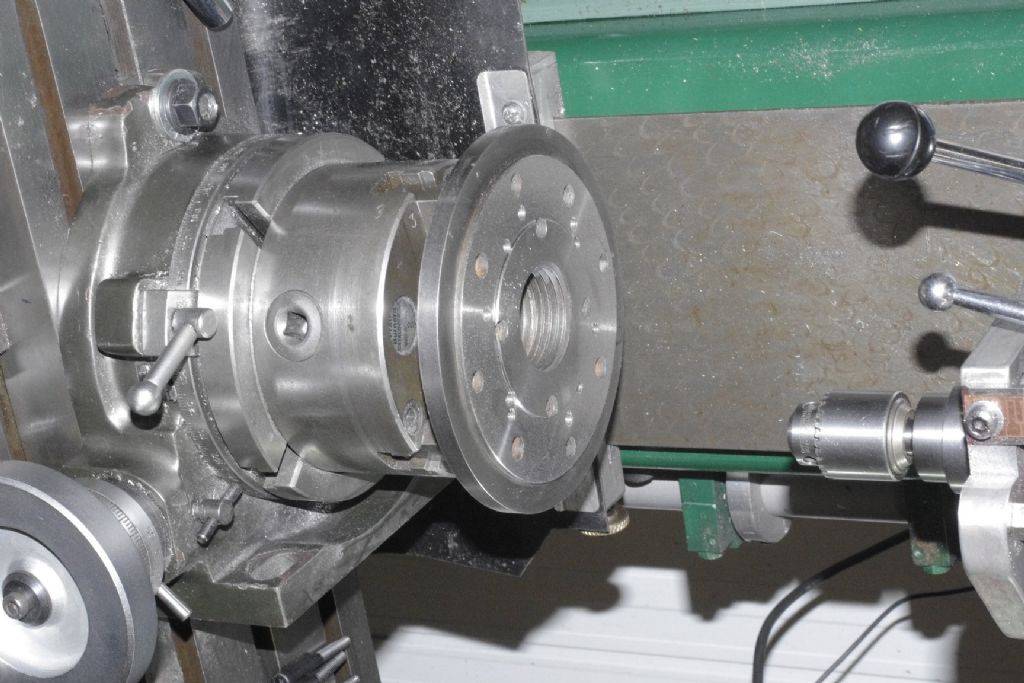

I have a Soba 5 inch table, it was the size that drew me to it as my mill (SX2P) is not that big. A 4 inch R/T seemed a bit too small and a 6 inch too big, I don't know if other manufacturers do a 5 inch but Soba do and I bought it as a set for £300 which is as much as I could afford at the time. It came with a dividing set, a chuck mounting plate and 80mm 4 jaw chuck and a tailstock.

In one or two places it is a bit rough around the edges but nothing much and overall it is good. Where it is very good is in its operation, I can't fault the table mount and the drive. It has no backlash, no play and the drive is very smooth and most importantly it is accurate.

So it may not look as well engineered or as pretty as the expensive tables but it more than makes up for it in its operation. So it met my budget came with extras and works very well, based on that I can't fault it.

Ron

Just in case it should be of interest to anyone with a small mill and is considering a rotary table here are the numbers from my mill with a 5 inch r/t.

Mill table to spindle 280mm

Top face of r/t above mill table 70mm

Face of r/t to spindle 210mm , (mounted horizontal)

Centre of r/t to spindle 137mm, (mounted vertical)

So it's not too bad for a small mill I haven't been caught out yet though I have been close with it in the vertical.

Ron

Michael Gilligan.

Michael Gilligan.