There are devices called quadrant photodetectors which are now very cheap and common, you can find one in the optical block of a CD/DVD player. As the name suggests the detector is four adjacent square detectors now made in the surface of one IC.. Lets call them a,b,c & d going around the centre. If you electrically add (a+b) but subtract (c+d) then you detect misalignment along one axis, adding (b+c) but subtracting (a+d) gives misalignment at 90 degrees to the first axis.

Using a small rotating beam painting a circle around the quadrant detector gives a constant brightness spot, Misalignment varies the proportion of the rotation that a quadrant is illuminated so we get a modulated signal which can be AC coupled to reduce steady state drift. So we could have two meter pointers, when both were reading no signal the circle would be rotating around the centre of the detector.

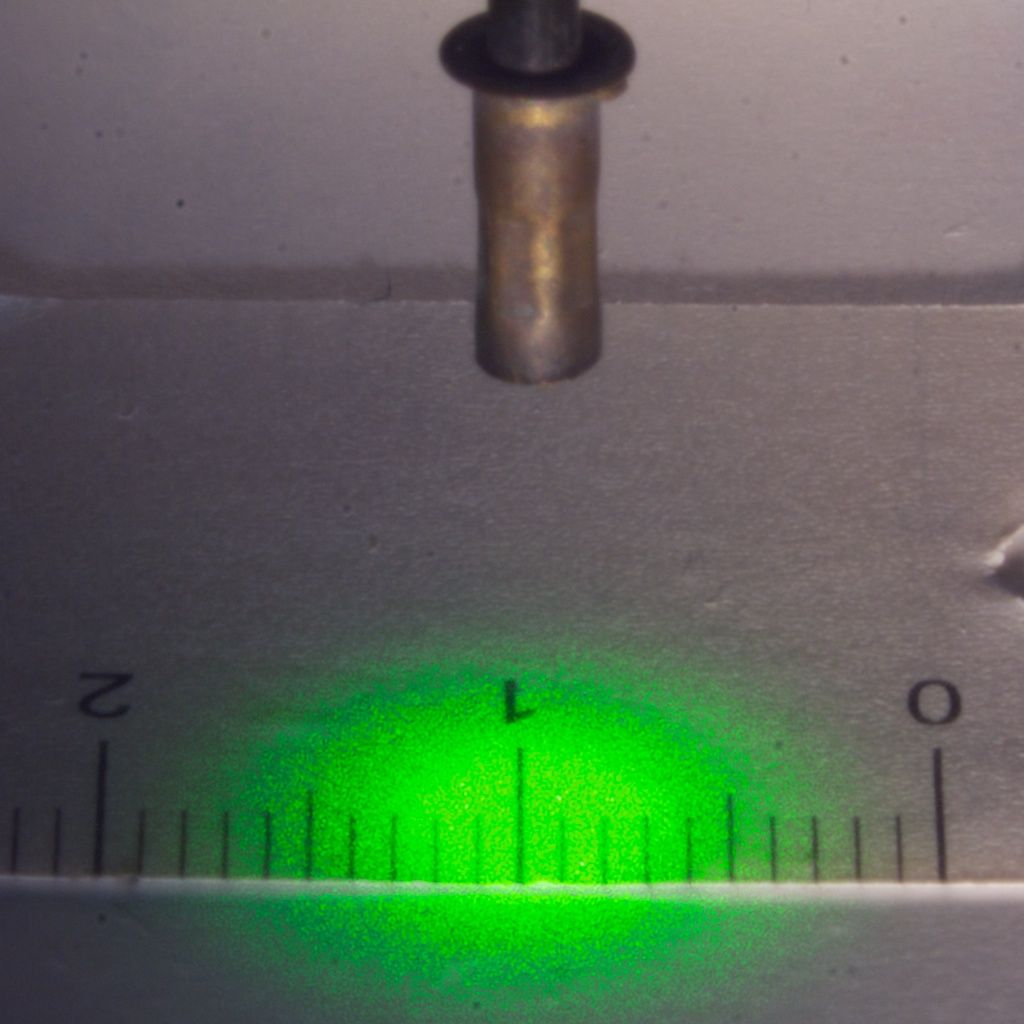

The quadrants are around 2mm square in some blocks, it is trivial to display microns with this arrangement.

Before anyone explodes off a high chair, this is a very well known set up with non-rotating sources. The Optical disc player uses a variation to recover height information . The player has a focusing lens driven by a coil actuator. The light from the lens is then sent through a round rod to create spherical abberation, the rod is at 45 degrees to the quadrants.

When the lens is focused on the disc surface the detector gets a round spot hitting all four quadrants equally. When the track is off then the detectors use the axis data to servo the lens to track the pits on the disc.

The focus is performed by adding (a+c) but subtracting (b+d), when the lens is too high the output is positive and proportional to the error, lens too low the out put negative. This is because of the cylinder lens abberation, out of focus the spot becomes eliptical, the major axis twists 90 degrees each side of focus.

This stuff was originally developed by Philips/Sony for the 12" video disc but was then recycled for CD & DVD players. The method of using servo's and quadrant detection is needed because you need micron accuracy to track the pits as they go around very fast on a disc that can go up and down several mm and also have the same kind of eccentricity. An all for ten quid for the player and electronics!.

You can use the rotating source and the quadrant detector to align co-axial shafts. A fixed beam can be rotated into a parallel rotating beam by rotating an inclined glass slide in the beam, that will scan the beam but it will not rotate a shaped beam. No fibers, no time domain measurements

Billy.

Vic.

Vic.