Hi Neil,

Yes there are a number of alternative ideas available for stiffening up these columns, including one where the owner added a bracket from the top of the column to the wall. Given that his machine was bolted down to the bench, which in turn was fastened to the same wall, this would seem to be a very secure and rigid system.

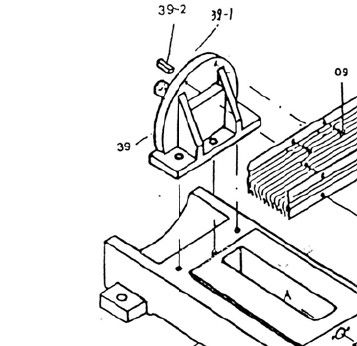

As I have not yet tried any of them, I cannot really comment, however I do favour the idea of adding a substantial U bracket to the rear along with adjustment screws to set and fix the various angles correctly and solidly.

Another idea which I do not think I have seen anywhere (apologies if I am wrong) might be to add bracing from the top of the column to the bottom of the column in the form of a triangle with the centre of the triangle being connected to the vertical centre of the column., eg.

cb

c b

c b

c b

c b

csssssssssb

c b

c b

c b

cb

where c is the column, b is the brace, and s is the horizontal bracing strut.

Just an idea!

Regards,

Peter G. Shaw

Edited By Peter G. Shaw on 18/11/2011 20:03:26

Edited By Peter G. Shaw on 18/11/2011 20:04:09

Edited By Peter G. Shaw on 18/11/2011 20:04:44

bricky.