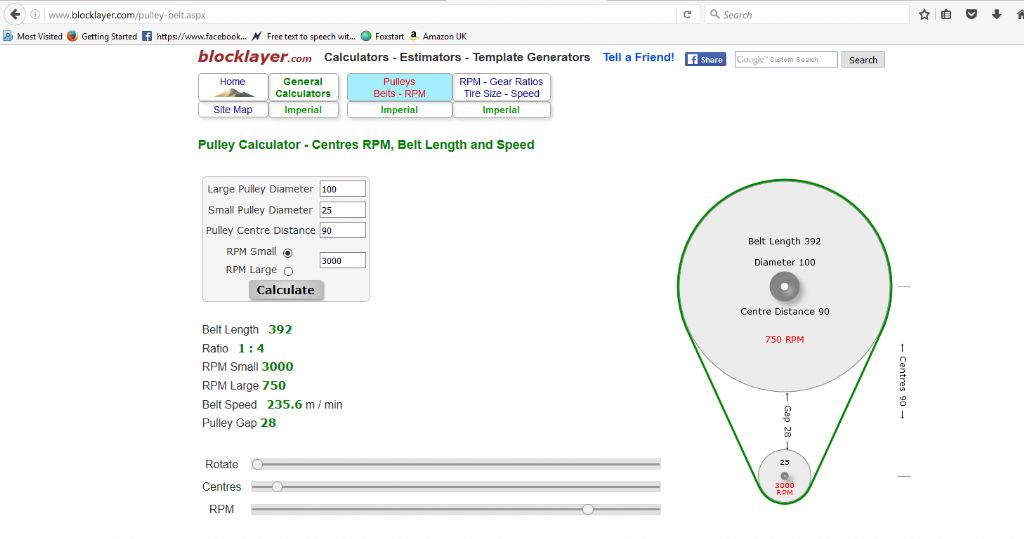

Recommissioning lathe size of hole to cut for belt

Recommissioning lathe size of hole to cut for belt

- This topic has 132 replies, 18 voices, and was last updated 8 October 2016 at 19:32 by

Martin Newbold.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- The strange phenomenon of Liquid Death

- Which Carbide Lathe Tools?

- Boiler Design – issue 4765

- Obscure Thread

- quality 3 and 4 jaw chucks

- Just How Many File Types Do We Need?

- Boiler hydraulic test 4 hours

- MD65 leadscrew cross-slide stuck in nut

- Fobco or a Clarke CMD 1225 milling capabilities? or other recommendations?

- Arc Euro Trade Ltd.

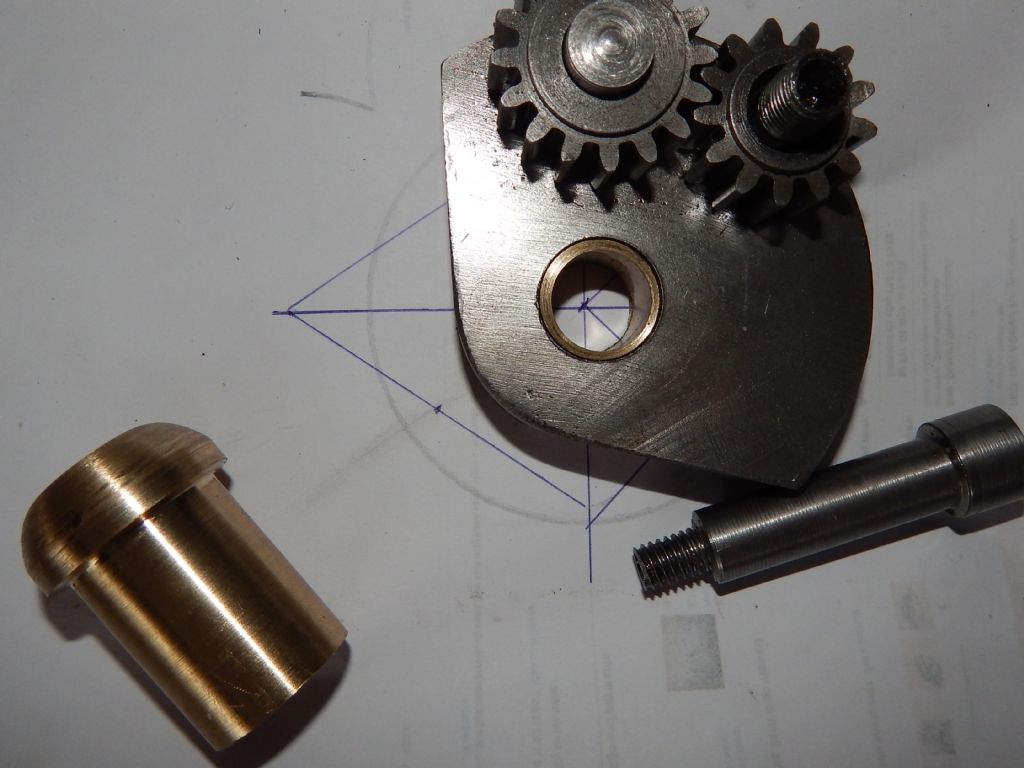

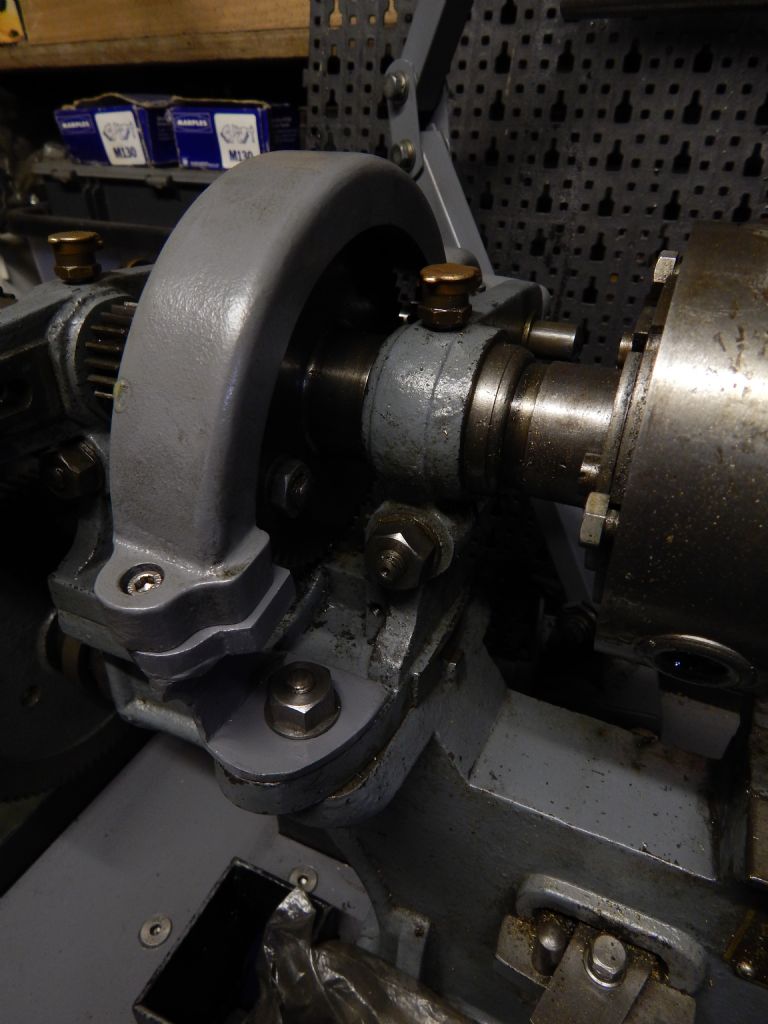

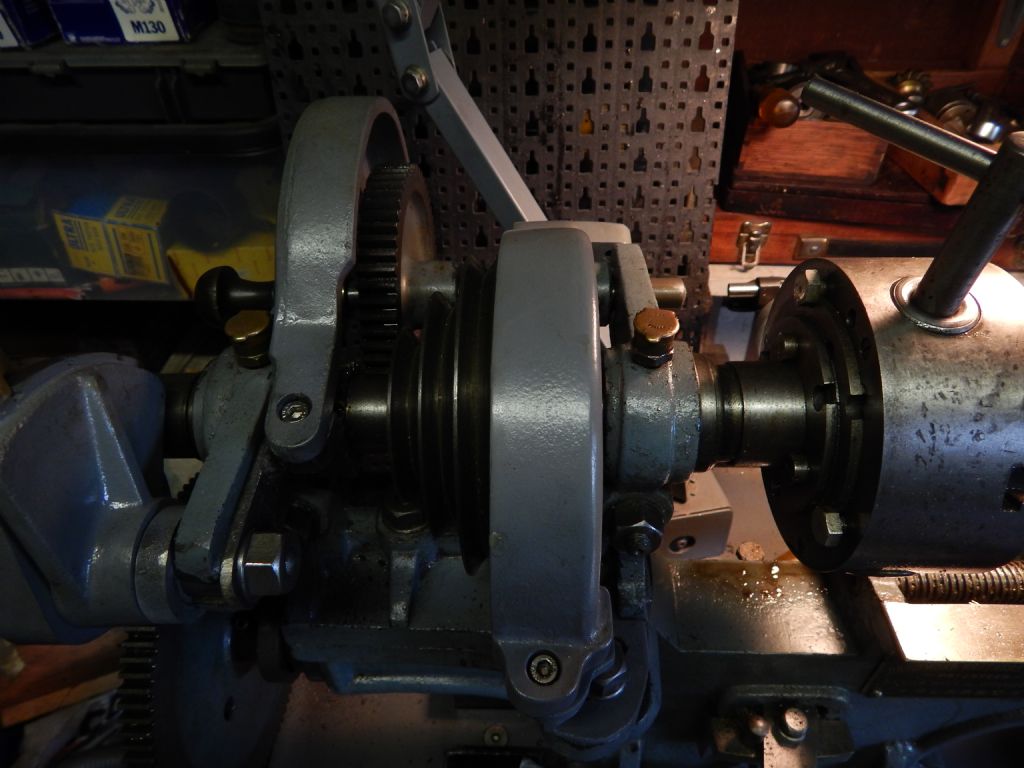

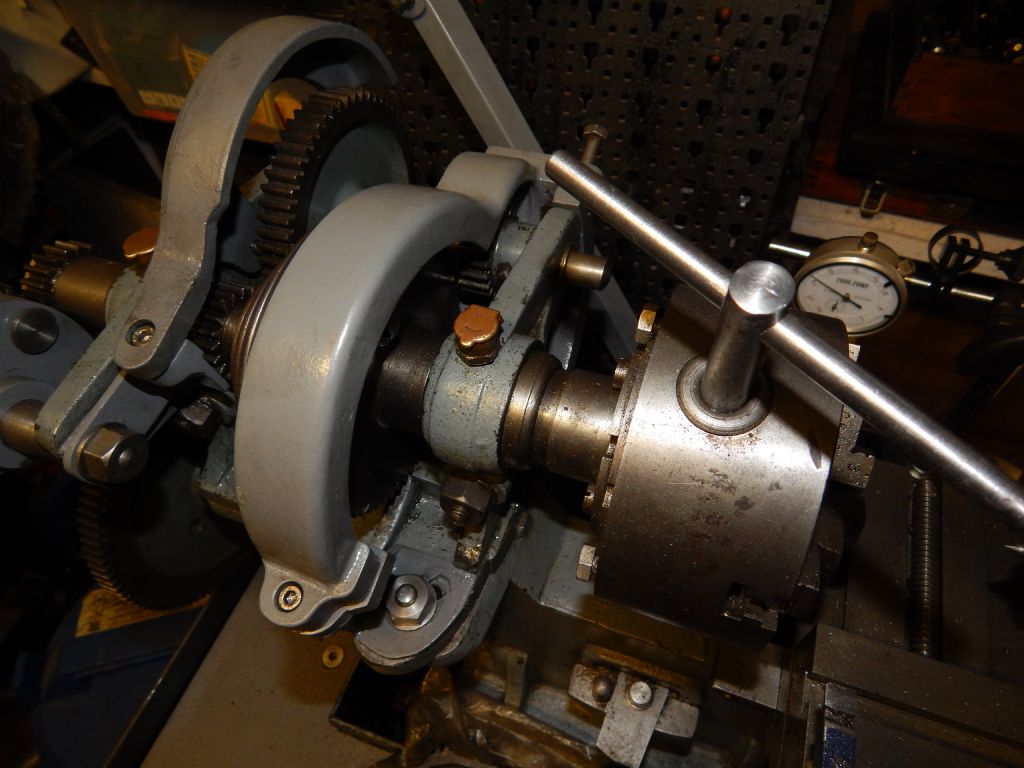

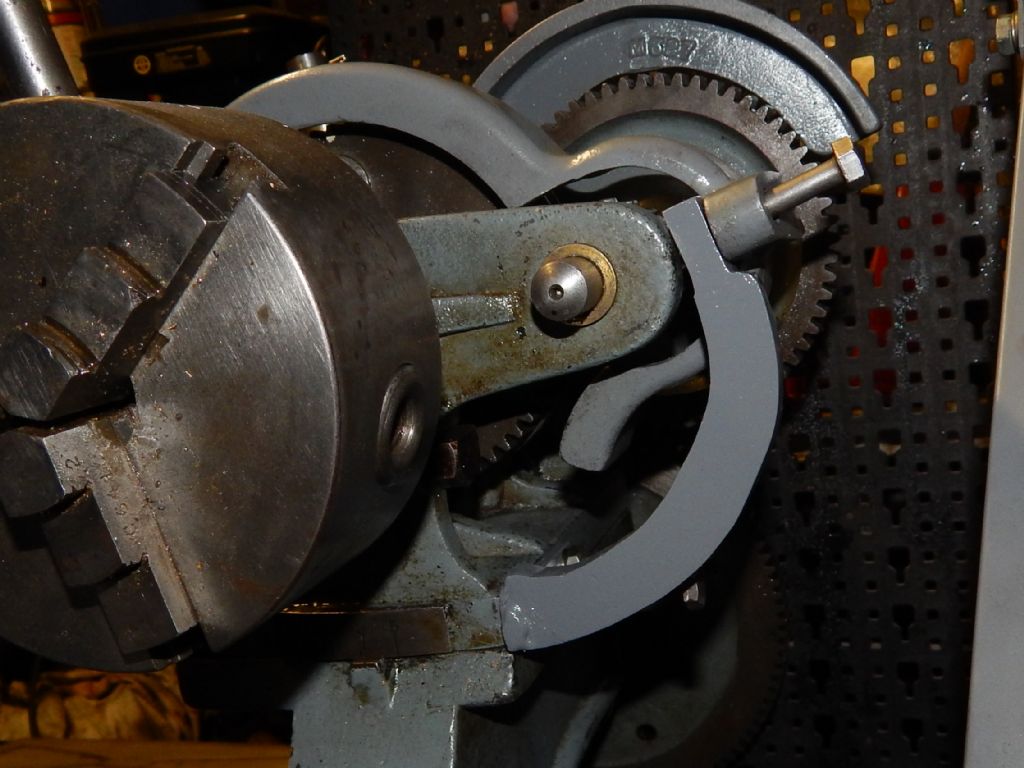

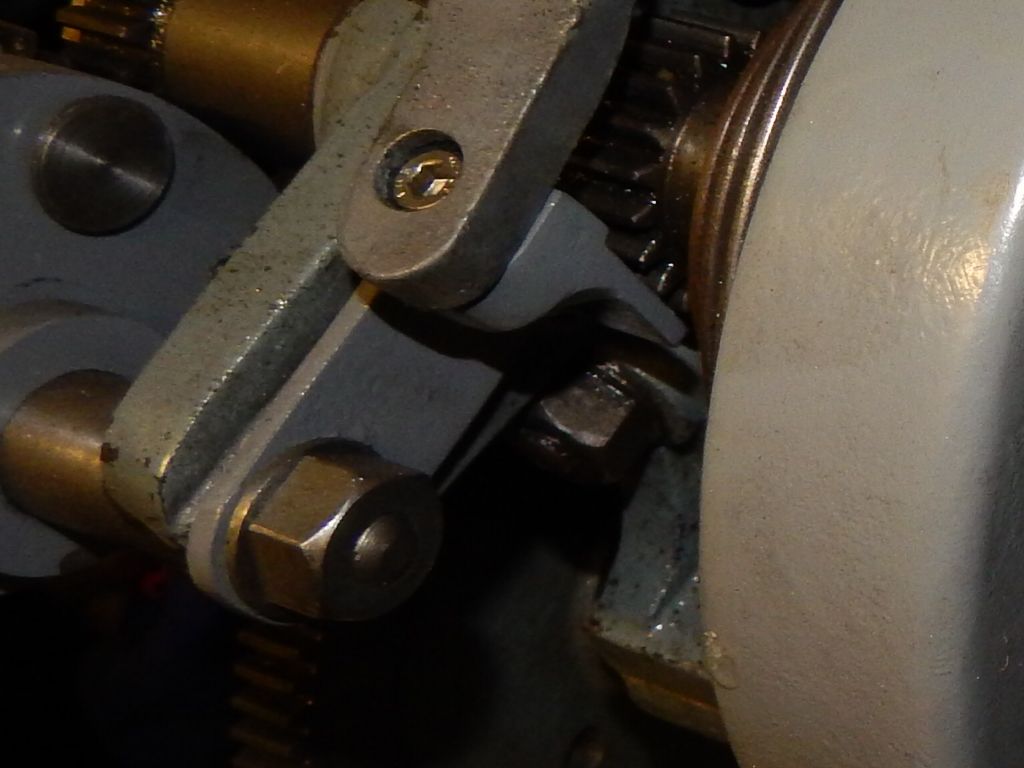

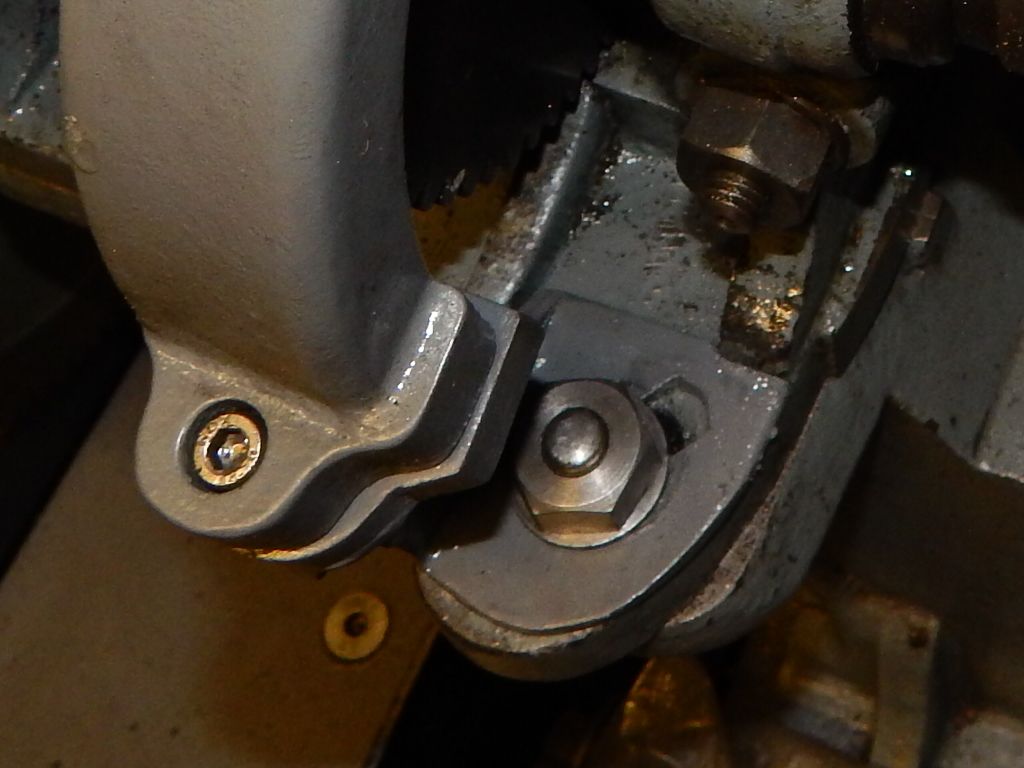

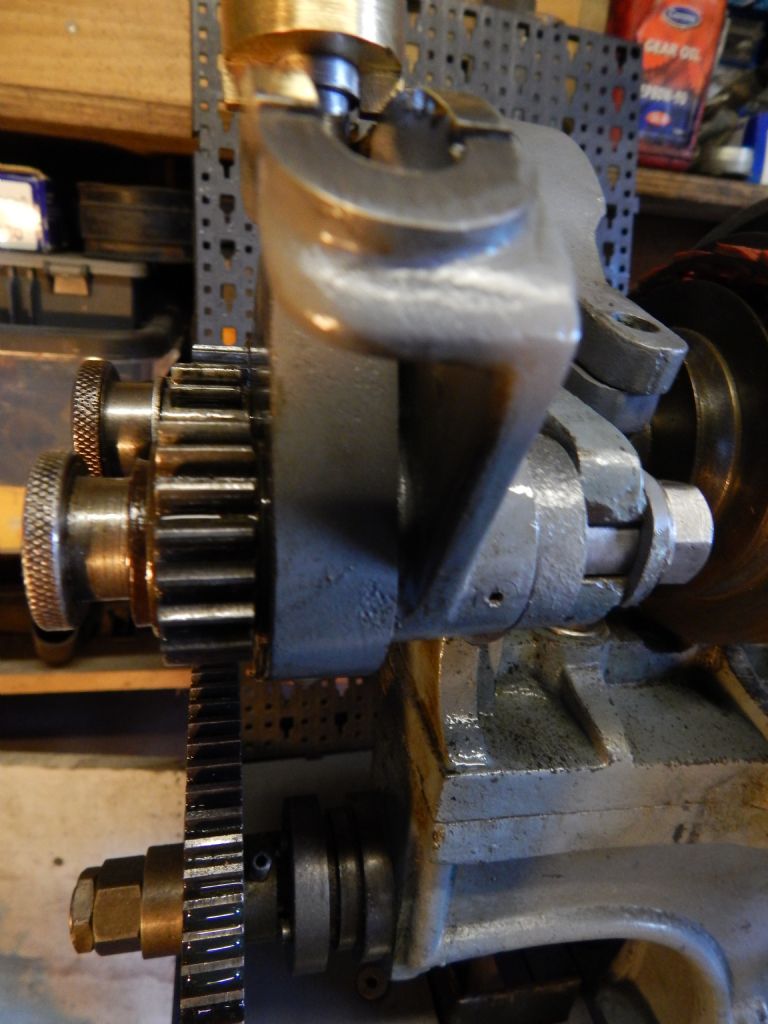

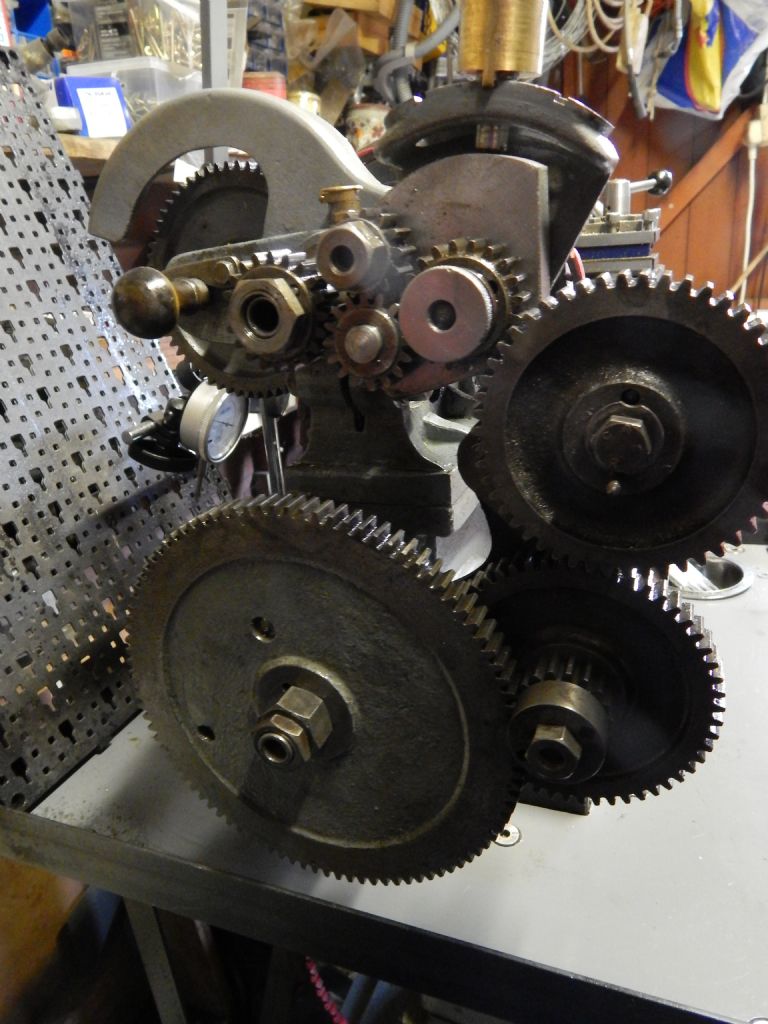

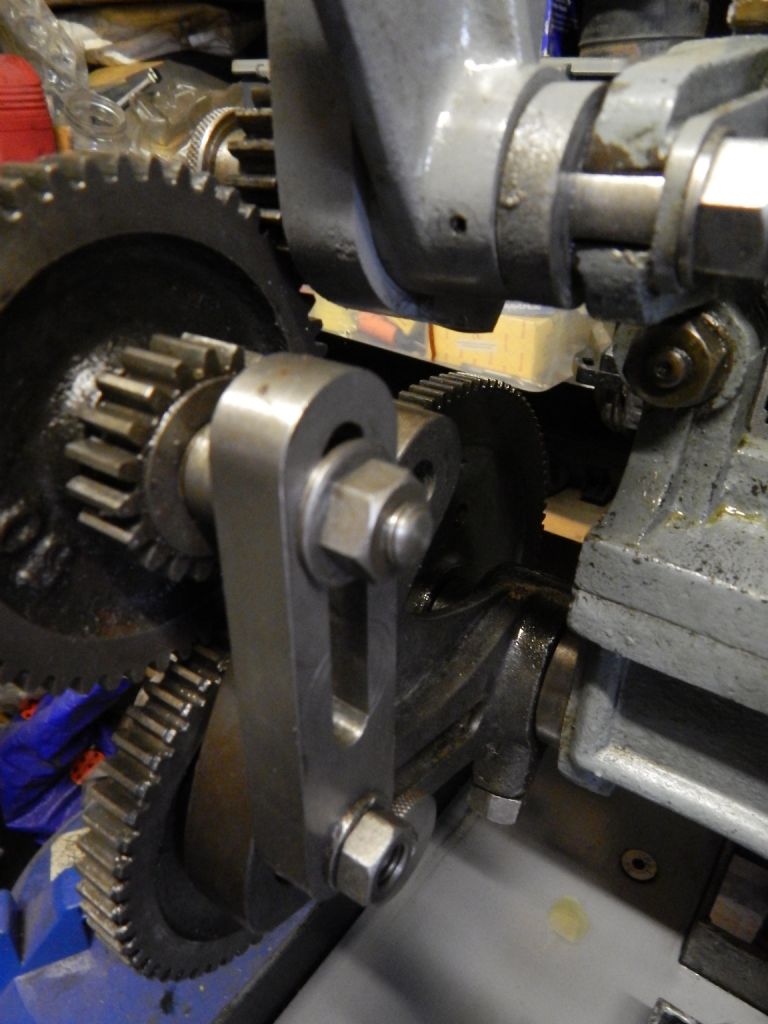

I re drilled my roll pin hole in the reverse tumbler to take 4mm pin as was noticing that the back section was movig slightly preventing neutral or no gear selection. Whith this done I made some new spacers to space the gears in line

I re drilled my roll pin hole in the reverse tumbler to take 4mm pin as was noticing that the back section was movig slightly preventing neutral or no gear selection. Whith this done I made some new spacers to space the gears in line