Posted by Emgeere”> 12/02/2019 10:04:39

John

Nice looking Quorn and a very well planned nest of swing out

drawers, is that your design ?

When grinding along the flutes of milling

cutters I thought the cutter should be ground

on the periphery of the wheel but above centre to

provide back clearance, how do you grind flute back clearance ?

Emgee

Just a matter of space saving ,some angle iron supports hold

the wooden trays on a single strut.

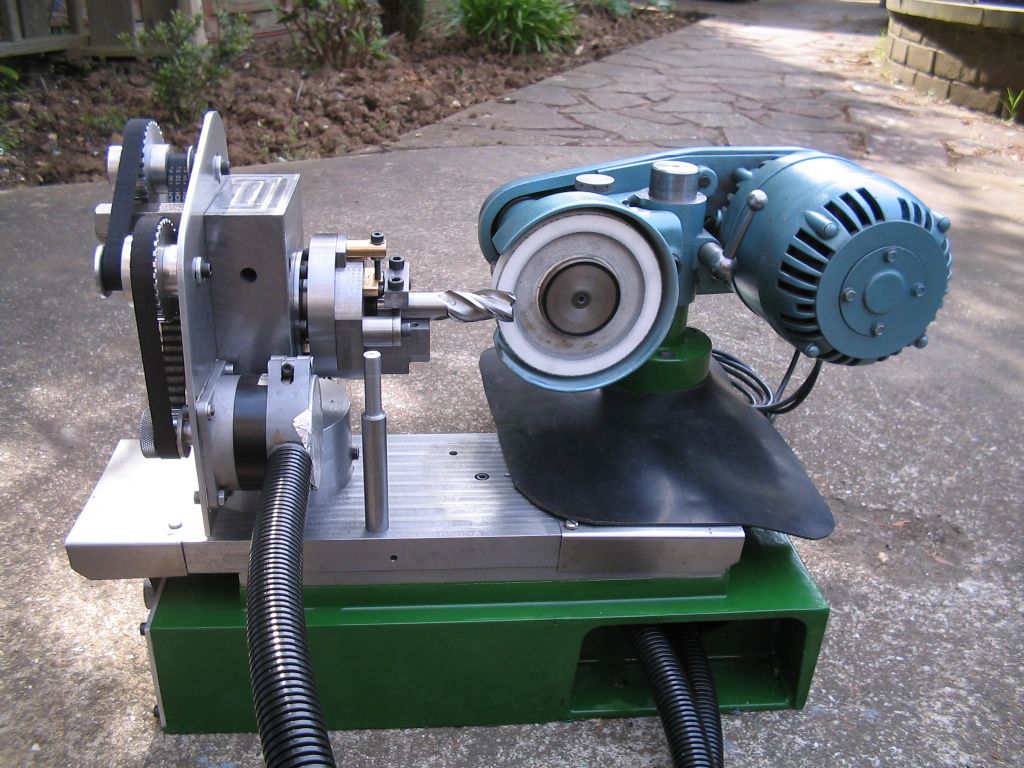

The photo shows in the foreground a post that is secured to the

table, this is a zero reference to the workhead axis,using a

dti the tip of the cutter is set to a zero position using

this reference.

Looking at the photo rotating the cutter anti-clockwise

increases the angle from zero to the desired amount .The

grinding wheel is at a shallow angle relative the the work

axis ,as can be seen by the black line around the edge the

point of contact is small as it should be.

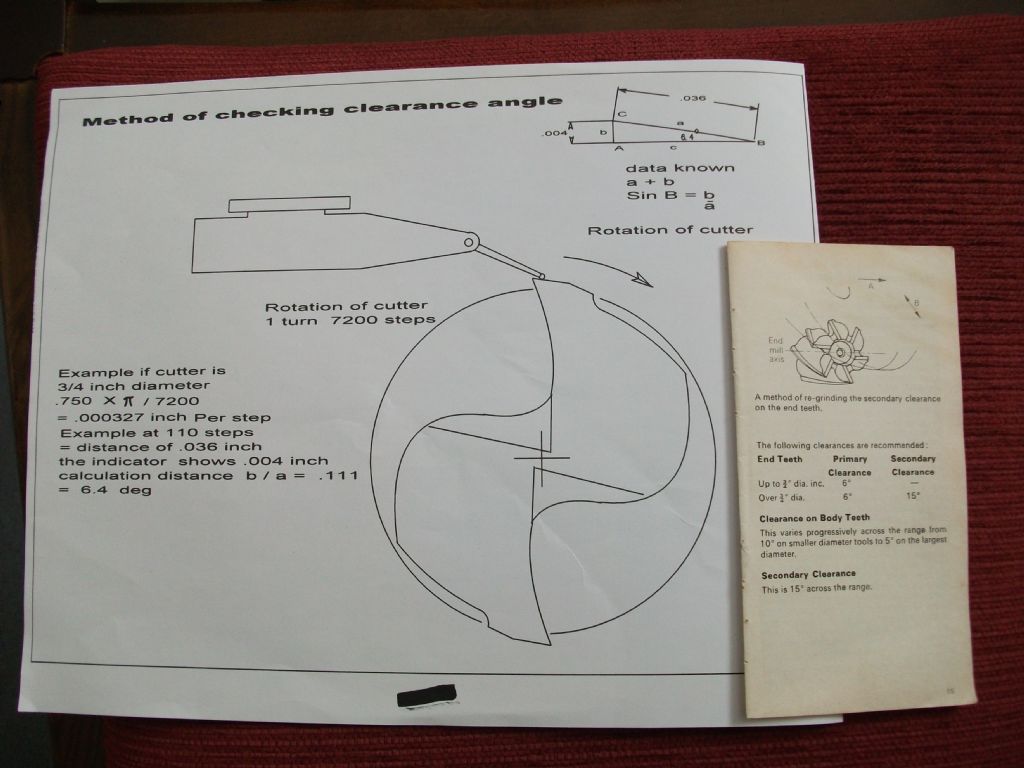

Early on when i first made and used this machine this is

how i would set up,now i use the same basic method but grind

first the secondary clearance. The Quorn book seems to show

the primary clearance as 6 deg ,in a Dormer handbook this is

shown as " Clearance on body teeth , this varies progressively

across the range from 10 deg on smaller diameter tools to 5 deg

on the largest diameter . Secondary clearance ,this is 15

deg across the range".

Setting 15 deg on the machine ,20 motor steps = 1 deg ,rotating

the work shaft 300 motor steps sets the 15 deg.

When the cutter is ground, the secondary clearance can be

measured on the machine as in the photo diagram ,since from

this the true angle is known it is a simple matter to rotate

the cutter to set the primary clearance angle.

Page 94 of the Quorn book makes reference to grinding

on the periphery of the wheel.

John

HughE.