Just purchased a Myford ML 10 from out of the Netherlands (I live in Belgium). It is in pretty good shape for its age and all tolerances appear to be tight. Only a few little problems to be sorted.

Warning: I’m a bit of a newbie with Myfords, so please bear with me. I’ve experience with metal lathe work (Sheldon, Taig, Unimat), just not with the British made Myford.

Stupid, obvious question first: What wrenches are needed for the Myford? Do I need to purchase a set of British (Whitworth) wrenches to use on the hex head bolts, or will American inch-measure wrenches serve?

A similar question applies to the Allen head screws on the lathe. It sort of seems like metric Allen wrenches fit (??), but can that be correct?

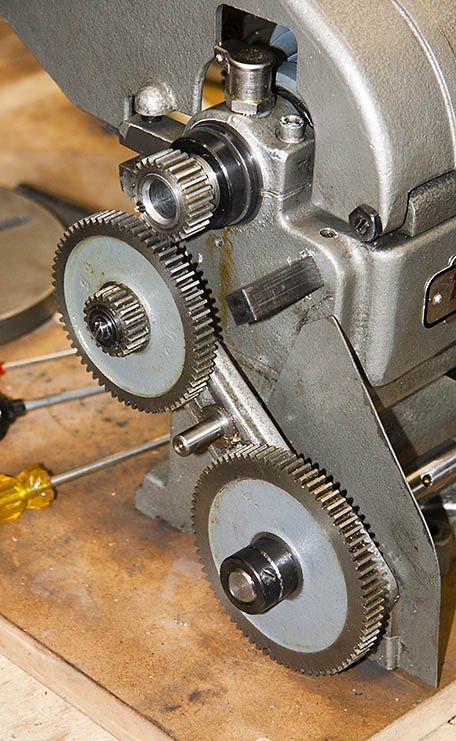

The biggest issue is that prior to my purchase most of the change gears went missing. That means no threading and no auto feed (horrors!). I see that almost all change gears are still available, either from Myford UK, RDG Tools or on eBay. My big concern here is that the splined bush for the center transfer idler gear pair is also missing. I could probably make it with a bit of fussing, but far easier if I could just purchase a replacement. RDG tools offers a change gear stud assembly. Is that what I am looking for?

– **LINK**

Another problem: The lathe came with two Pratt Burnerd chucks. The 4-jaw independent is just fine. The 3-jaw self-centering chuck is missing two out of the three external jaws. Are replacement jaw sets for these chucks to be found? Or is it simpler to avoid the grief and just buy another (complete) 3-jaw chuck for external use?

I see from the literature that a dog clutch was once available for this lathe. I don’t really need to tackle this issue right away, but it would be quite useful to have in the future. It doesn’t appear to be so very difficult to machine such, but are there any plans or literature available to help me with this?

Any other tips or pointers gratefully accepted.

Edited By Ignatz on 12/07/2017 07:58:20

Hopper.