William

Although I don't have one, I know that dial gauges mounted on bedstops are very useful for folk without a DRO.

Whilst you are at it do make provision to replace the dial gauge with a rod to give a positive stop for jobs like cutting up to a shoulder. I consider coming up to a hard stop much less stressful than watching a gauge.

Apart from the relative fragility the primary disadvantage of a dial gauge is the limited travel. Given suitable creativity it ought to be possible to come up with some means of temporarily fitting a vernier or digital "vernier" calliper to monitor the movement of the stop rod when pushing it up to the finish position with the saddle. The start point zero having been set by touching the tool to the end of the work before moving it clear to push the stop rod back. If it weren't for the calliper being upside down putting it on the tailstock side might be more convenient as there is more room at that end.

A fork shaped upstand for a depth micrometer (if you have one) might work well. Set the micrometer first then rest it in the fork. Move the saddle up until it contacts the probe. Lock saddle, lift out depth micrometer and set the rod to the saddle.

Or you could use an internal micrometer in a similar manner to set the rod for the longer cuts. Needs large enough setting surfaces to give something for the internal micrometer to work against but it seems feasible for all but the very smallest of lathes. I'd probably make the stop bigger to incorporate separate holes for the dial gauge and stop rod and a small flat face for the internal micrometer. Need more than one length of rod I expect.

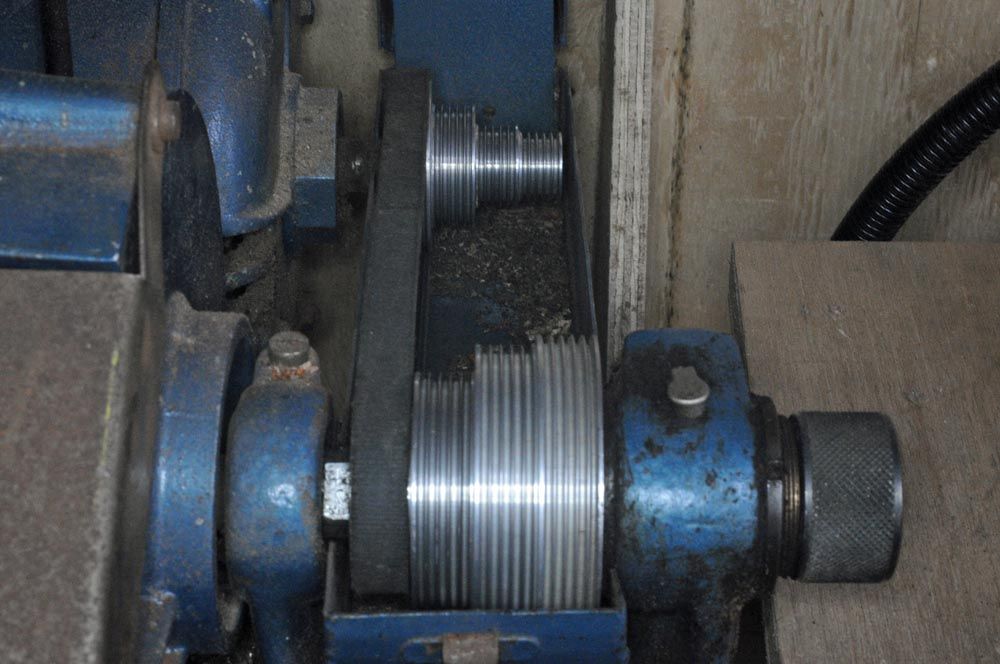

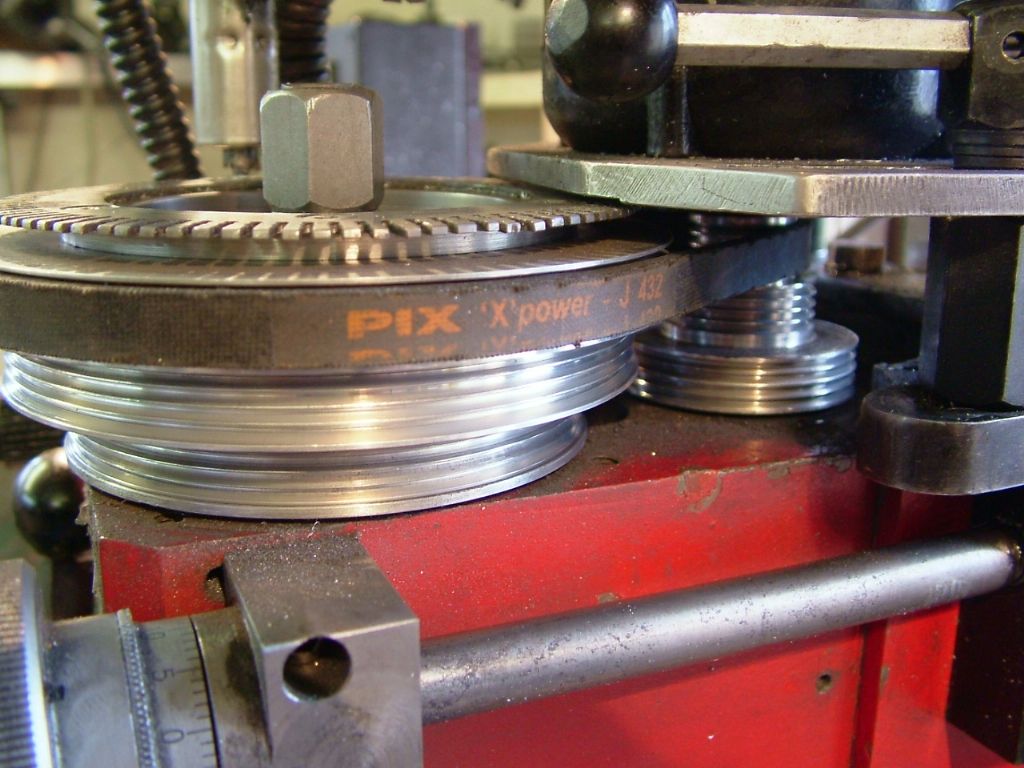

I have a micrometer bedstop and six position rod type turret. The combination work well for me. But my lathe has an accurate travel indicator on the saddle.

Clive

oldvelo.