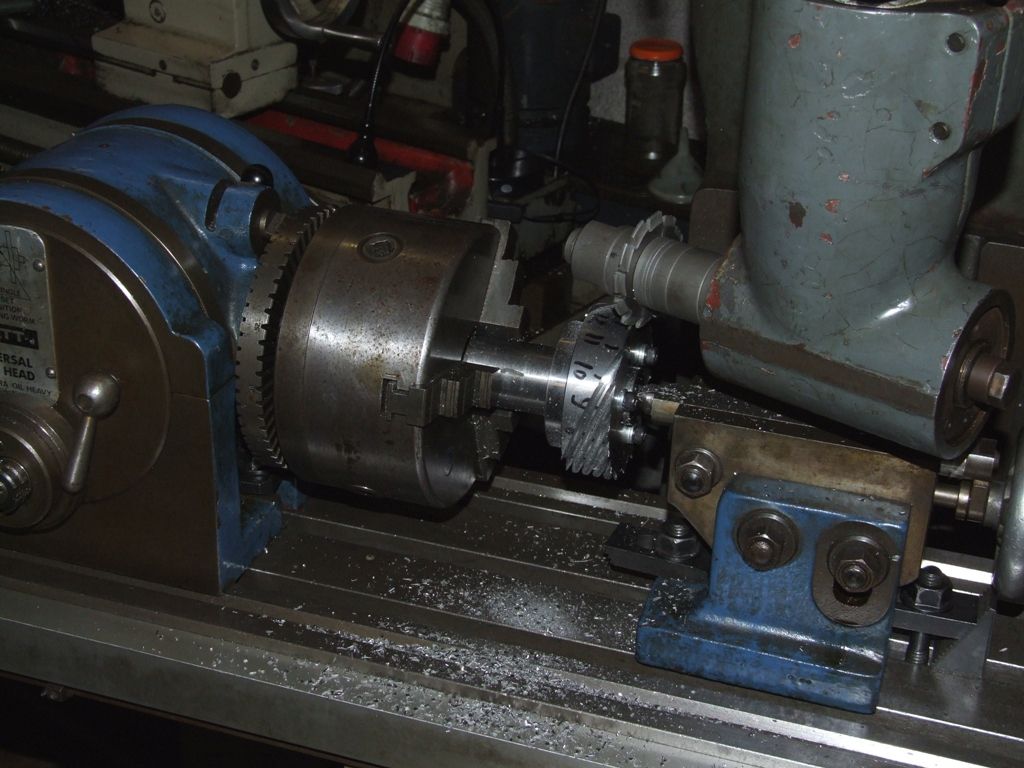

I have an Elliot 00 omnimill ,it was a gift from neighbour, I was proposing to downsize my property and my Elliot big turret mill and my large Adcock and Shipley 2E horizontal mill very reluctantly had to go . I had 40 years ago owned a Tom Senior MI mill with vertical head, . The senior could be used horizontally and vertically with the vertical attachment, vert spindle was 2MT so a bit limited, overall the build quality was better than the Elliot,but it sadly lacked capacity particularly under the spindle, A similar sized Harrison has more capacity. The Elliot turret mill only had a 30 int taper which was really too small particularly for a machine with a 50 inch table but I earned a living with it. The Adcock was close on 2 tons and fully universal with a removable vertical head both spindles no 40 int, good make and solid great for spiral stationary engine gears and heavy milling, though it was a bit worn on the knee cross slide, It was probably used on one job which required continuous use of the Y axis,must have been hard work without power feed and it was obvious from the different shade of grey paint that the screw housing assembly had been changed at some time. x & z axes were OK . Movingonto the Elliott was a bit of a comedown though it does have some good points, its easy to use, plenty of capacity particularly under the spinde,both spindles are 3 mt so tooling is common,VERY easy to change from vertical to horizontal without any lifting,I had to get help when fitting the Adcock head. rigity of horizontal spindle is good ,vertical not so good ,not rigid enough . Recently I made bronze blow down and boiler feed valves for a full size steamer and coped very well with this work.Mods to omnimill so far, took handle off Z axis and made a lot longer handle winding up was difficult, the small spare handle is now fitted to table feed so there is now a handle at both ends of table much better. Vertical head removed depth stop and fitted a one inch thick steel plate to quill and one side of the plate is attached to a hole tapped into the overarm now very rigid ,plate is a split clamp on the quill so by releasing the screws the quill can be used,and it can be used at an angle .The other nuisance is the lowest speed on both spindles is too high for my kind of work a six inch saw on the horizontal runs far to fast for cutting steel, so I have plans to reduce spindle speeds,they are ok for ali and brass but not steel with large dia cutters it also came with a slotting attachment which is very good and I have also aquired a two axis vertical attachment at some cost but cannot complain as the machine was free,total weight is 12cwt. So for model making the 00 is good,well thought out machine but has limitations, though is a far better bet than imports. So generally the Bridgeport type mill is the best option,the horizontal mill can really remove metal,attachments are heavy,and horiizontal machines were generally used for production runs ,where bonus earnt meant more to the operator than taking care of the machine,though occasionally you come across a lightly used horizontal.

Howard Lewis.