Sean & Mark, I hope I'm not muddying the waters here, but I've just checked both my sets of BSW thread gauges; first set only has the TPI marked on the blades and is stamped "7G", the other, like Sean's is stamped 7G 11/8" 11/4" but these diameters only refer to BSW threads, so don't be misled

N.B. The thread gauges are marked up as BSW, though they can be used for BSF, as they are the same thread form i.e.55 degree, rounded crests etc. just different TPI

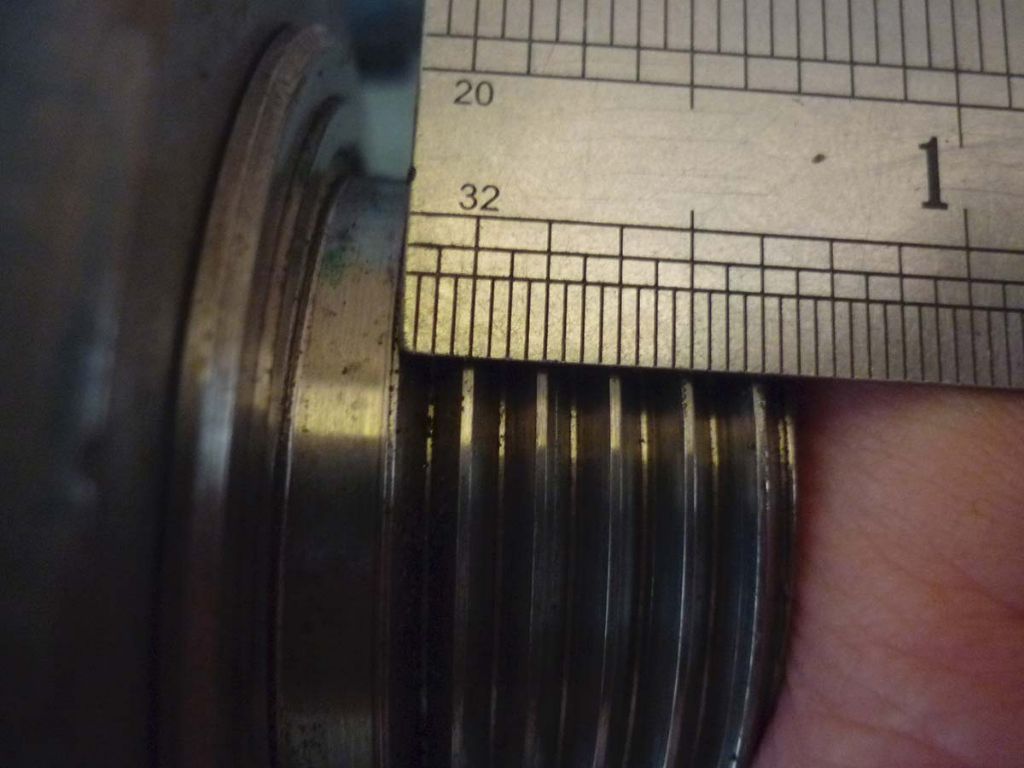

This tallies with my thread tables as 7TPI for both these two BSW threads (11/8" & 1/14" ), on a normal standard nut and bolt, so I'd suggest that the lathe nose is actually 7 TPI not 8 TPI

In your case you seen to have a 13/4" lathe nose with 7TPI. This would equate to 13/4" BSF

The actual thread measurement for BSW/BSF will always be smaller than the actual thread nominal OD size as the thread form has rounded peaks.

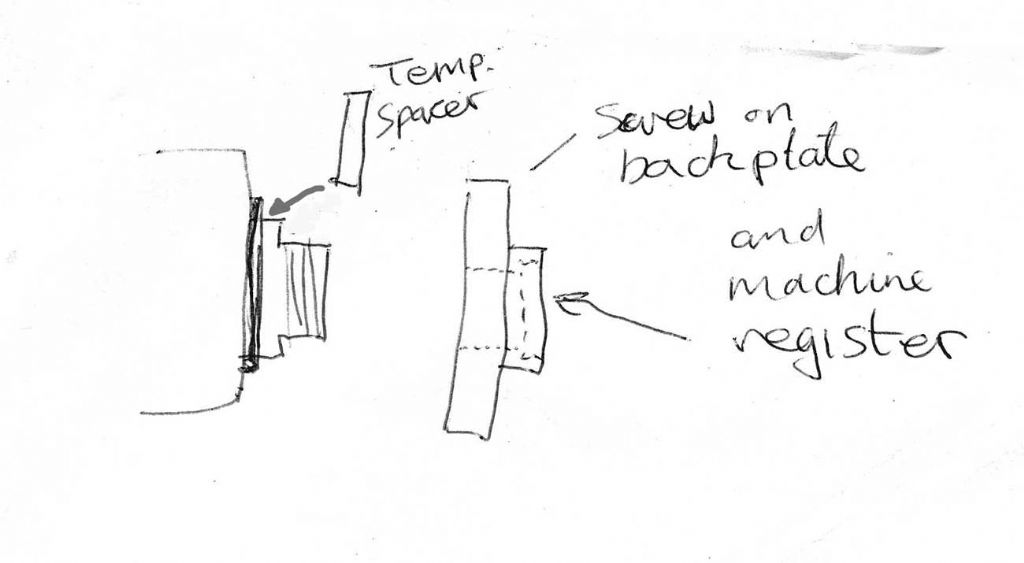

Ergo, you seem to need a backing plate with a 13/4" 7TPI BSF thread form, with an appropriate register diameter to suit your lathe.

It does strike me a little odd that you've measured/shown 1.8" register and 1.7" thread diameter on your sketch. I'd have expected the thread to be slightly smaller to allow for the rounded crests (@ 1.6585" )and the register to be almost bang on 1.75" Are you sure your measuring equipment isn't about 50 thou over reading?

I think Michael & I were typing posts at the same time, but I got delayed part way through.

I wonder if the daylight is just due to half a century of wear on the thrust side of the thread on the nose? It won't make any difference to the accuracy of the chuck Sean, as it's the register which positions it; the thread is just to keep it there, but it might explain why you could partially engage what is effectively a 8TPI nut on an 7 TPI bolt.

Could it be the thread binding up, and not the register being the wrong diameter?

P.S. I'm not trying to teach anyone to suck eggs here.

Edited By peak4 on 18/12/2016 21:30:57

mark smith 20.

each machine have their differences even though they are the same model ,if that makes sense . I see different sizes for my bore out there . My thread major size is 1.75 + – a thou or two ,what's my bore size going to be . .

each machine have their differences even though they are the same model ,if that makes sense . I see different sizes for my bore out there . My thread major size is 1.75 + – a thou or two ,what's my bore size going to be . .