You need to work down the grades of abrasive, when all the lines are from the current one, it’s time to go onto the next. With f lat material this is easy as the idea is to use each grade at right angles to the previous one, making it very clear when the marks from the previous one have been fully erased. Do not buff! This will seriously round the corners and remove detail, unless you are using it for a final light polish. It’s difficult to keep it even a Drexel would be even worse, too small and easy to form depressions, tiny, but so obvious when a high finis is wantedAlways use abrasive on some form of backing, hands are rounded, and just holding it will round the work. Sticks, files etc can be used.

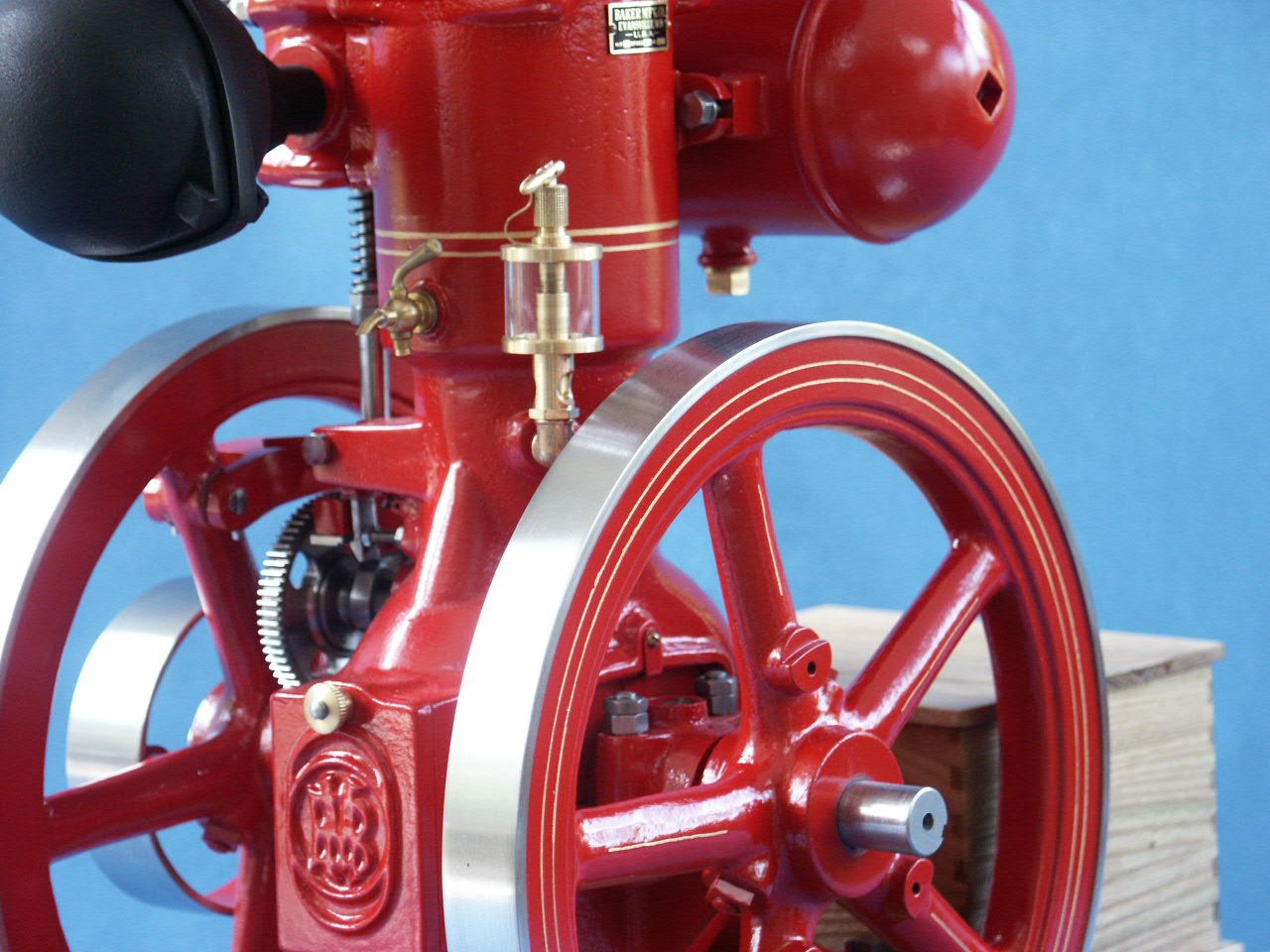

If your flywheel is cast iron, a mirror finish is difficult due to the natural micro holes (or pits) found where the free graphite in the iron was previously located. Good luck mirror polished work in my opinion always looks so poor, it’s completly non standard some people seem to polish everything, although it does have its place with brasswork, but not machined components

Edited By Zan on 30/10/2018 18:29:14

Edited By Zan on 30/10/2018 18:33:35

Nigel McBurney 1.