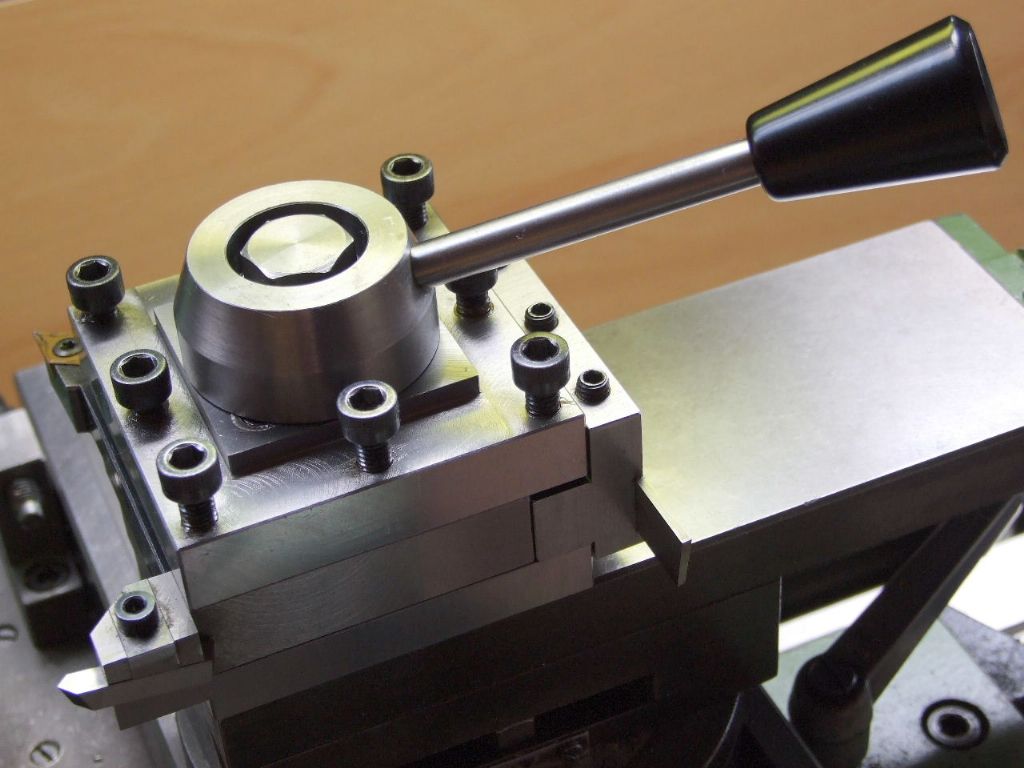

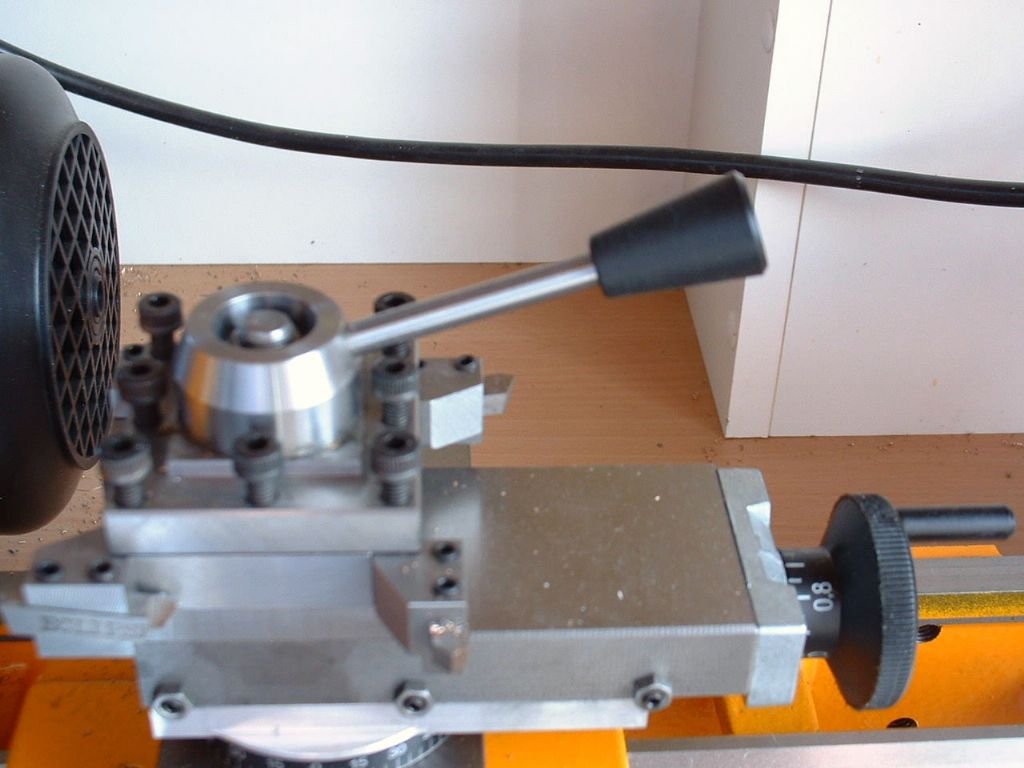

Thanks very much for the compliments. Yes the toolposts are an adaptation of GHT's. I fear some may have thought the two photographs above are one in the same. For clarity I have shown below the two versions.

Going back to the front rake. If one considers a tool will zero front rake then it will not cut as the point cannot penetrate the surface. If it cannot cut it certainly cannot dig in, is my theory. Therefore as the front rake is increased the tool point is allowed to cut, but with some resistance. A small front rake thus gives a self limiting action to the tool and is I feel why it does not dig in. This theory may be unfounded, but 40+ years of metal turning have shown this procedure works. Take the front rake to an extreme and this resistance is lost, the tool can literally bite off more than it can chew, with a calamitous result.

One thing a reduced front rake does require is a tool set on centre height. If the tool is above centre then it has zero front rake and will not cut. Conversely when below centre then the front rake increases with the usual calamity. The parting tools in my 4 tool turrets are automatically on centre height as they were made to be so.

Just as a passing example, the Hardinge HLV lathe I once worked had a Multifix tooling system. The HSS blade in these holders had a "U" shaped groove ground in the top of the parting blade, with a small land either side. Obviously the cutting edge is now much longer than the width of the parting groove. The "U" had the effect of curling the chip in on itself. Not that dis-similar to the inserted tip blade profile.

The section of this blade might be found interesting given that the Hardinge is about 5" (127 mm) centre height. The blade was 2.5 mm wide and approximately 11 mm high, not what would be expected on this size of lathe. Yet this tool would handle all the tool steels used in my profession.

Regards

Gray,

Oily Rag.