Posted by peak4 on 10/04/2017 21:11:38:

This might seem a really silly question, but why does the lathe have to run in reverse?

Being entirely self taught, I don't have the benefit of wide and varied training, so I've never seen one of these before.

No it's okay,

The lathe has to go in reverse because the tool would be presented on the "wrong" side of the lathe. The conventional way has the work piece rotating in an anti clockwise movement down, and into the cutting face of the tool.

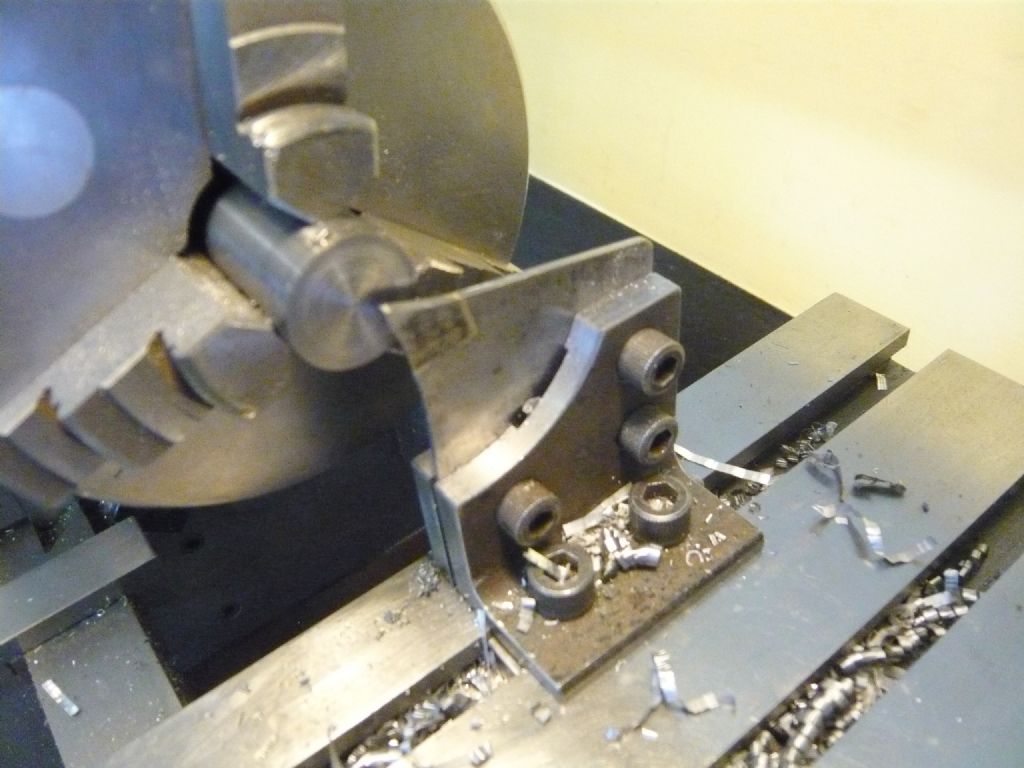

Working from behind the lathe, a rear tool post cannot hold a conventionally ground tool because the workpiece would be rotating, still in an anticlockwise movement lets presume, up and into the underside of the tool, not cutting in the way you want it and most certainly rubbing rather than cutting.

It is because of this that the tool has to be placed upside down so that the right cutting face is presented, with the clearance angles all there, to the work piece.

A lot of cheap lathes in the past did not have a reverse function, so the lathe would only spin in an anticlockwise way, so came the rear toolpost, along with it's upside down tools,

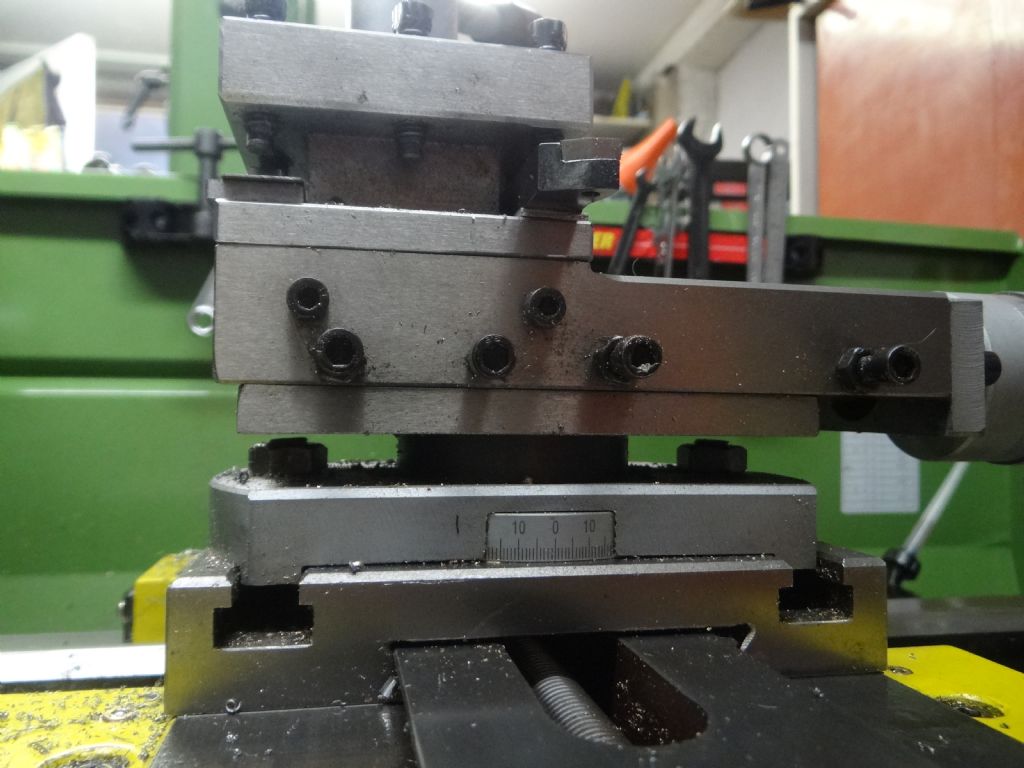

this also meant that if the user was canny, they could have two toolposts in play without needing to stop to switch tools for parting off.

The theoretical reason why it is also good for parting off is because the tool is less likely to slip under the work piece, be drawn in and snap either the tool or the work piece, normally the tool. So a rear tool post would encourage the tool to go "up" and away from the work piece rather than the opposite. This tends to happen if the tool is too low on the centre line.

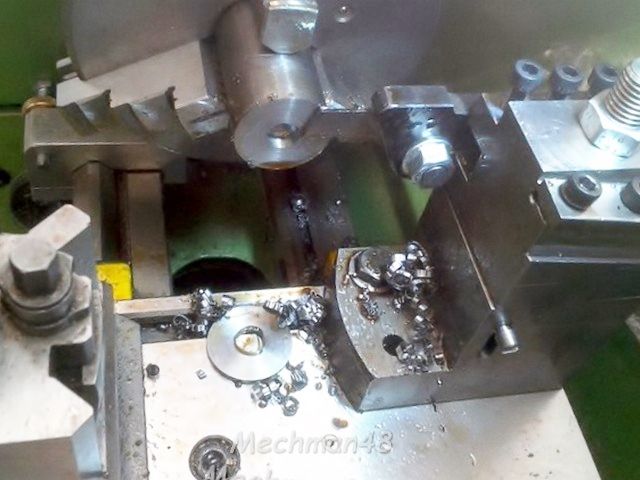

(Very nice tool post/ parting off tool, Tractorman!, Is that two, separate, dovetailed slides on the same cross slide?! )

)

Michael W

Edited By Michael-w on 11/04/2017 07:12:02

SillyOldDuffer.