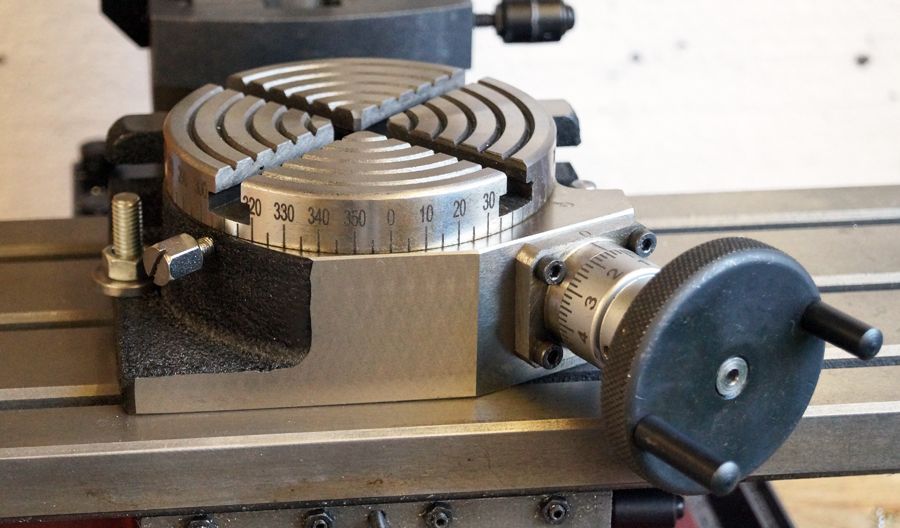

My Warco 100mm rotary table arrived this morning, should anyone be considering one it may be of interest to know what I found with mine.

At £56 which includes VAT and delivery I was expecting the table to look cheap and possibly nasty but I was pleasantly surprised. Obviously it doesnt look like a table costing five or six times the price but for the money it could look a lot worse.

After cleaning off the protective gunge I did a few checks. Turning the drive handle felt very smooth all the way around a full rotation of the table with no tight spots. There was however a few thou of end float in the drive spindle plus a similar amount of backlash when rotating the table by hand. There was no float when pushing the table from side to side plus no lift between the table and base so that was good.

I then stripped the table down to see what was what and if there was any adjustment available. Adjusting the drive spindle end float is easy to do by taking up any slack with the graduated drive boss which is held by a single grub screw. The adjustment for the table backlash is made by adjusting the mesh of the drive gears and the way this is done is crude to say the least. The geared drive spindle runs in a tubular housing which has a square fixing flange, this is fastened to the base by 4 caphead screws. There is a grub screw in the base casting which when screwed in contacts the outside of the spindle housing and pushes it closer to the table gear despite the housing been fixed to the base by 4 screws. Very crude and not too good on the engineering front but having said that it works.

I played with the adjustments for some little while to get a balance between the feel and operation of the drive handle and a reduction in any play or backlash at the table. Checking with a dial gauge I managed 0.001" end float on the drive spindle and between 0.001" and 0.002" rotational backlash on the table, it varied around the full 360 degrees. Also the table lock acts horizontally on the side of the table and this pushed the table off centre by 0.002" when locked.

So all in all I think the table is good when you consider the price, I dont think you could expect much better. I am going to look into improving the gear adjustment and I am going to make and add a 150mm adaptor plate to it.

Ron Laden.