I managed to find the pictures from when I made the modifications to my S7. Date stamp is Nov 2014, doesn't time fly when you are having fun!

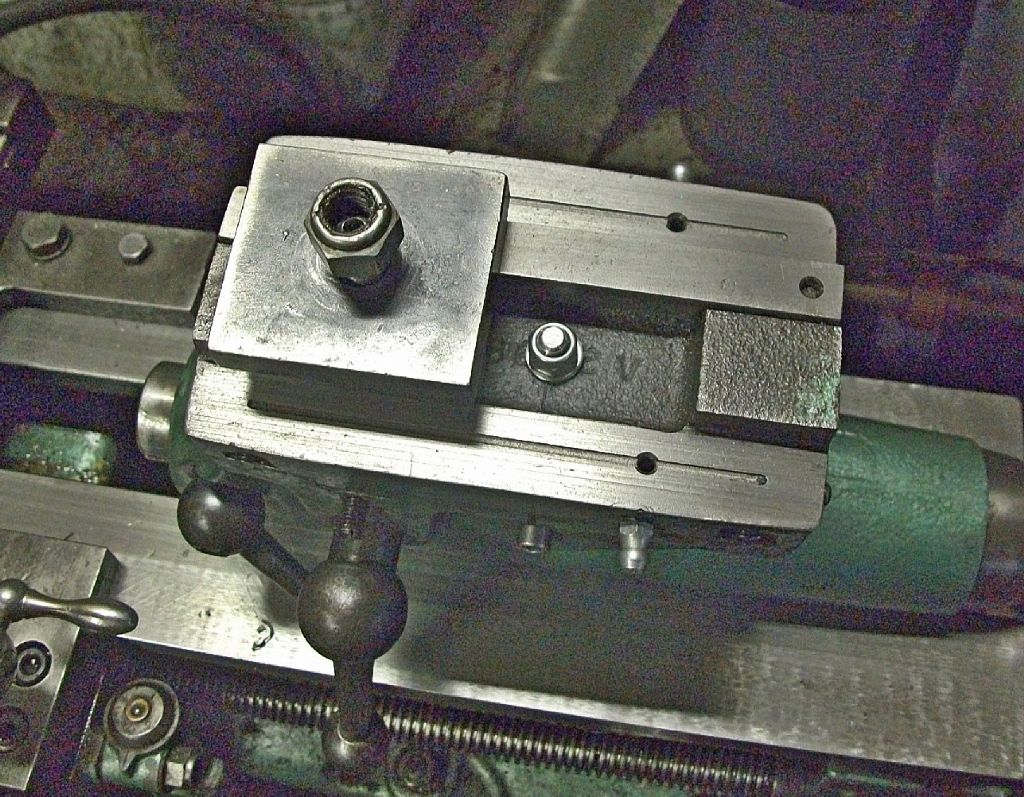

Now I recall the tailstock needed two oil nipples as it wasn't possible to cross-drill the bottom block. The oil nipples have to close to the rear of the tailstock so they don't clash with the saddle when working right up to it. You will see if you push the tailstock up the saddle that it comes a fair way back along the sides of the tailstock.

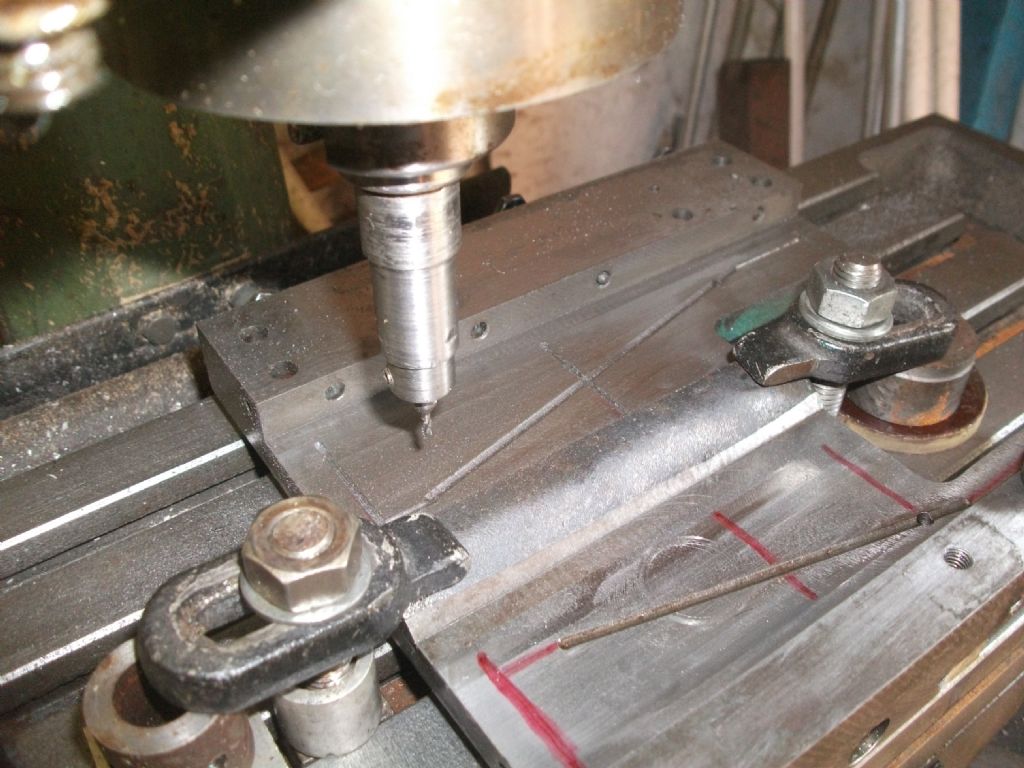

The saddle was ground on the working faces and then I cut the new oil grooves. The exact placement isn't too critical, but the intention was to get the cross grooves as close to the outer sides as possible so some oil can get to the vertical shears. The original oil grooves leave a large part of the slideways starved of lubrication.

On my saddle the portion at the front looked like corduroy trousers where the swarf chips had become stuck and abraded the cast iron. Hence, I had the saddle working faces surface ground to remove these imperfections. This is another reason to improve the swarf guard to improve the wiping action. Without the swarf felt wiper the saddle acts like a vacuum cleaner and the dirt gets pushed under the saddle to cause mayhem as the normal oil grooves cannot flush out the muck. It just made a lovely grinding paste!

Oil grooves in tailstock base

The other modification which prompted all of this work was the tailstock riding upwards as it has no positive vertical clamping apart from the bed locking clamp. When the tailstock gets a bit worn as you slide it along the bed it is possible that the top portion rides up slightly and a piece of swarf can get into the gap at the front. This causes the barrel to tilt upwards and upsets the centering. So I made an additional clamping arrangement. Note this modification is not for the faint hearted as you need to drill some holes in the castings, but with care it is not too difficult to do and the end result is worth the effort. If anyone wants the details then just shout. You can see the additional clamp bolt nyloc nut in the picture of the tailstock base.

Extended oil grooves in saddle

John Fielding.