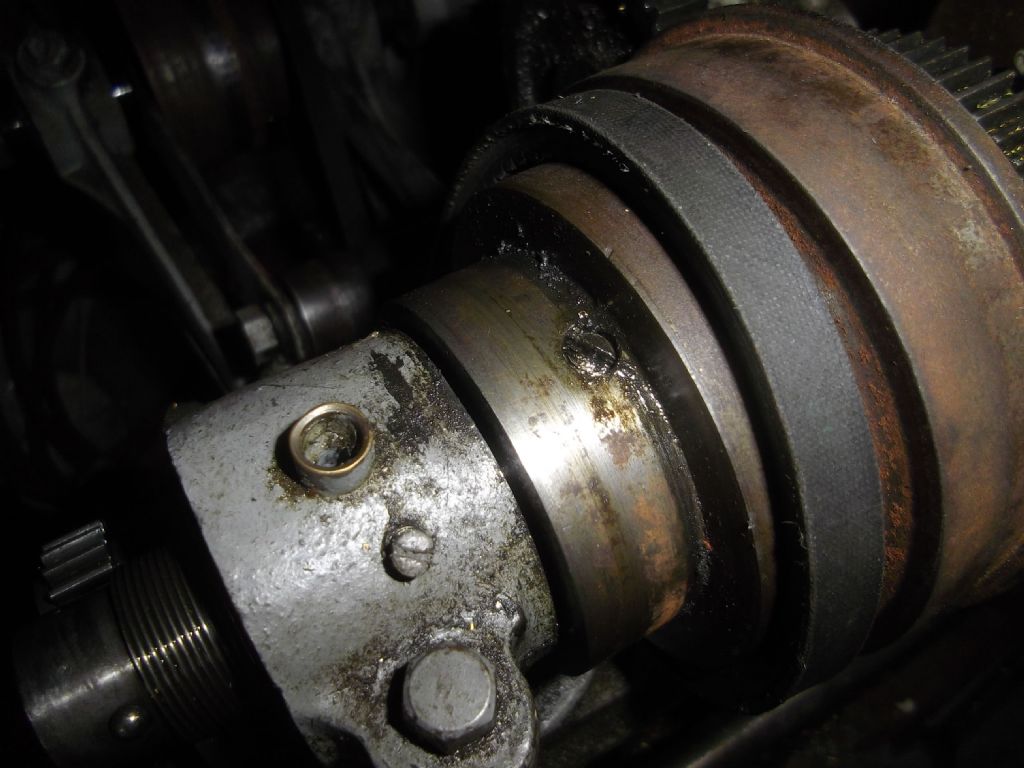

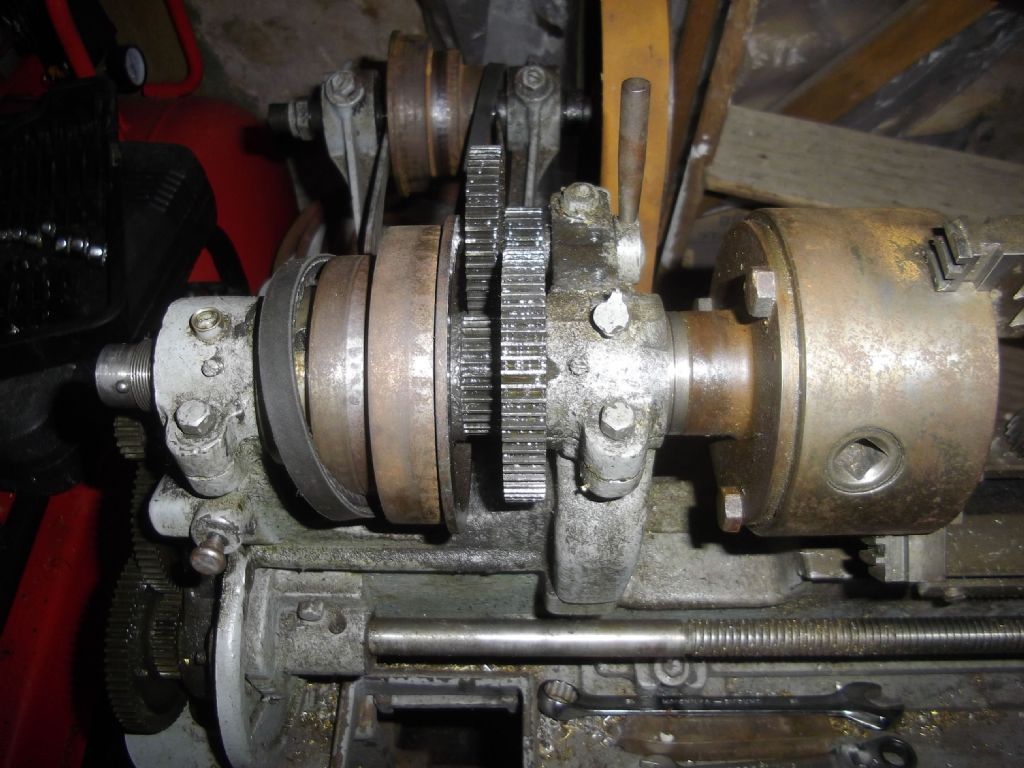

The Change Gears on ML4s and their predecessors are pinned (3/32 pins) and are easily damaged by trying to use them to lock the Spindle for removal of the chuck I made a few replacements for a friend who used to use this technique on his ML4.

Take a look at lathes UK website for ML2, 3, and 4 info. There is a specific warning about engaging Back Gear without loosening the Grubscrew, forecasting damaged gears if you do this to lock the spindle to remove a chuck.

This months M E W (274 ) has an article on a simple tool and way of locking the spindle on a the ML7 for chuck removal, without risk to the gears, and this could probably be applied in a similar manner to the earlier ML lathes.

Gripping a piece of timber or steel bar between the chuck jaws, and administering a sharp downward whack on the end of the timber often works as a fairly low risk means of slackening a chuck.

Another way is to grip a fair sized hexagon in the 3 jaw chuck, and apply a socket and a long bar, to slacken a sticking chuck. Again, a suddenly applied torque, via a mallet will be effective.

My 8 inch 4 jaw chuck has a 5/16 hole in the rear flange into which a bit of 5/16" silver steel, clamped to a piece of 1" x 5/16" x 12" flat bar is placed, ready for the impact of a copper/hide mallet. Has worked every time for the last 15 years!

Prevention is better than cure: make sure the threads, male and female are clean and undamaged, and don't spin the chuck on under power , or even fast by hand. Light lubrication may prevent rusting, if that is a concern.

Howard

Nick Wood.