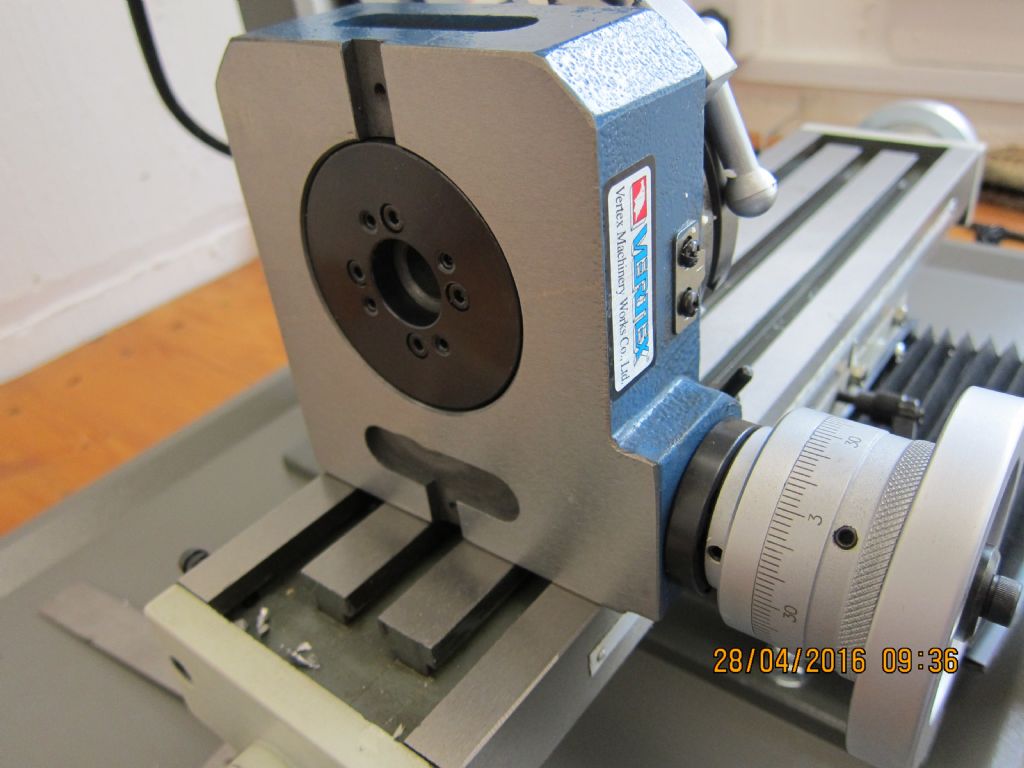

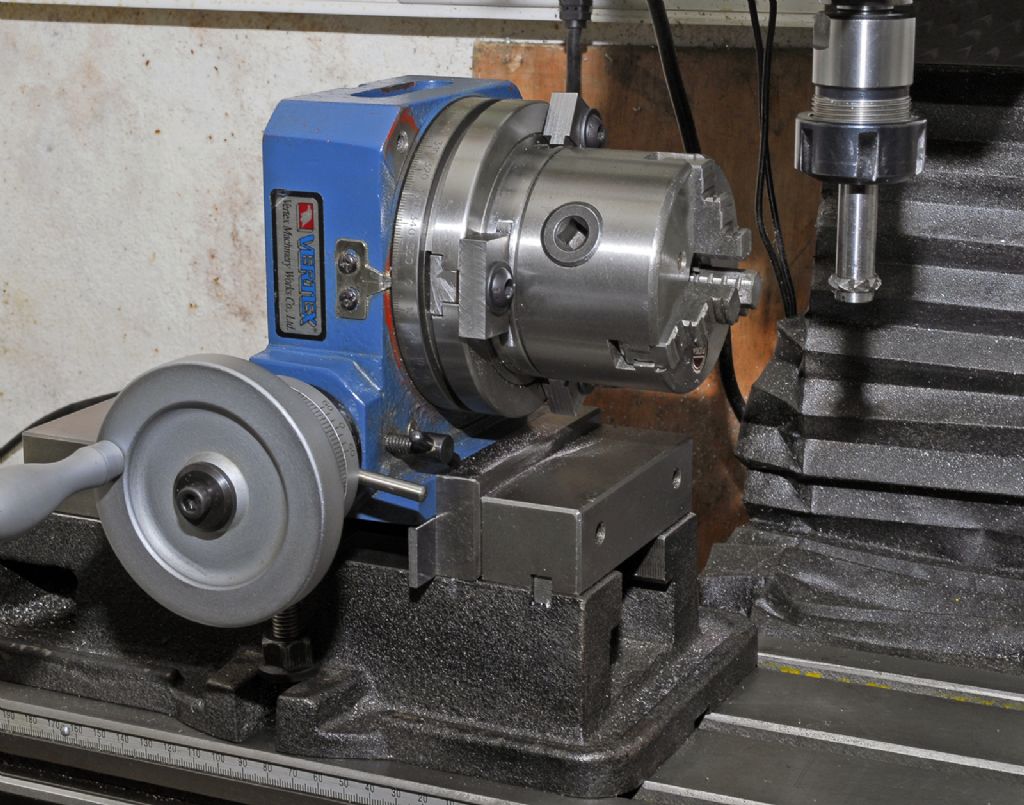

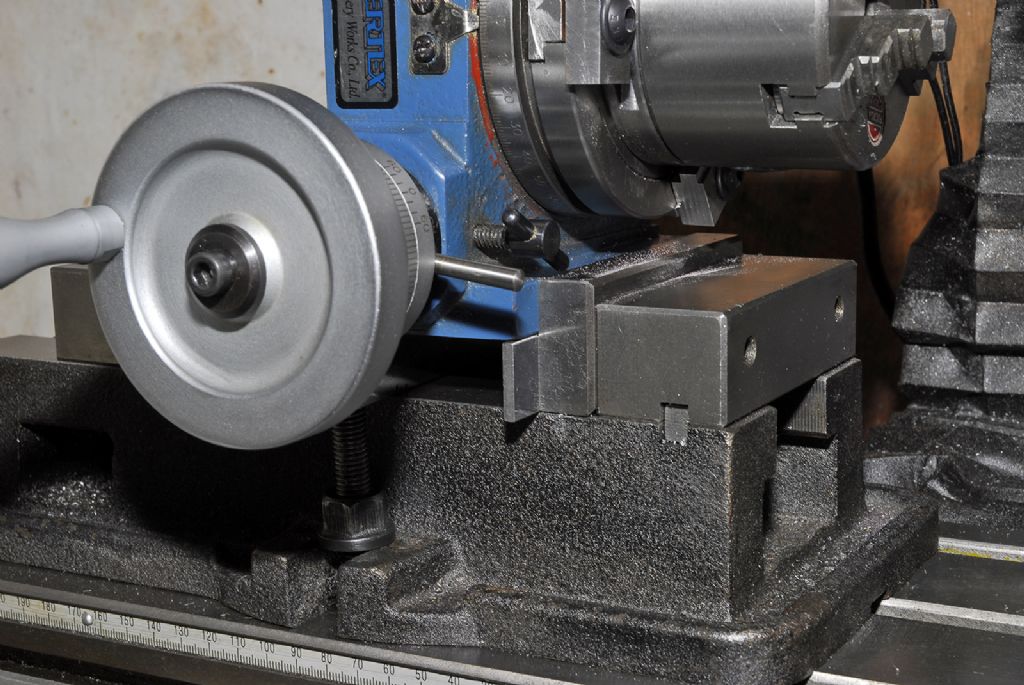

Mounting a Vertex HHV 100 Rotary Table

Mounting a Vertex HHV 100 Rotary Table

- This topic has 40 replies, 19 voices, and was last updated 8 May 2016 at 00:26 by

Paul Lousick.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Boiler hydraulic test 4 hours

- Just How Many File Types Do We Need?

- MD65 leadscrew cross-slide stuck in nut

- Fobco or a Clarke CMD 1225 milling capabilities? or other recommendations?

- Arc Euro Trade Ltd.

- quality 3 and 4 jaw chucks

- Model Turbines

- Pragotron Slave Clock

- Miniature parts maker in Leicester?

- Pratt Bernard Grip true issues