Well it's been a while since I revisited this thread but I've been waiting for a shaper to come along to make my ME work easier. Took me 2 years to get one and I've been doing various bits'n'bobs meantime

Got the shaper at last…then puppy wuppy gets ill and decides to shuffle off her mortal coil so after all that I got about a month of free time before puppy wuppy 2 is due at the end of this week so I thought I better write this up… until I get to the next instalment in 2 years time…

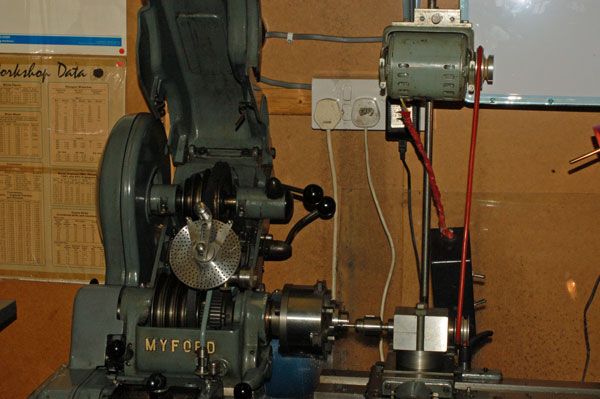

The support bars are about a fiver a pop fencing from B+Q, as is the square drive rod running along the top, they are bolted onto the lathe with 10 or 12mm B+Q threaded rod, there's a big lug at the headstock end of a M-series lathe which makes things miles easier.

The tailstock end is supported by the bottom half of a spare tailstock I had.

Onto this has been placed a 1 inch thick lump of a broken lorry leaf spring I found by the road, banana shaped at first but the shaper flattened it out nicely to take a broken bit of cast iron vice and a lump of scrap from the box, all secured together via more 12mm threaded bar from B+Q

The ebay bearings are mounted inside some scrap gas pipe I half-inched from outside a neighbours house when a plumbing job was being done there.

Mounting the bearings to the support bars for the drive shaft was going to be a bit fiddly and it was at this point I broke out the 40quid Lidle welding unit I got 2 years ago.

After a bit of practice at birds nesting I tacked each pipe to the support bars, aligned them properly then welded them as best I could.

About 3 hours fiddly ME work was done in 15 minutes with that welding kit and it all seems to be nice and solid

The bearings were tapped back into the pipes and then the 2nd part of these pipe bearing carriers screwed home.

An old lathe belt cone was fettled into position at the headstock end and some old used bits of plastic lathe belting were candle welded back together to make the big drive belt

It runs rather nicely, whirring away with only a little vibration from the too stretchy belting,

Torque at the drive bar is moderate to low, only mild drilling to 6mm max I would say but this is mainly due again to the stretchy belting.

It's going to be fun experimenting with this thing, it definitely has a lot of potential.

Hopper.