Thank you for the replies,

It's good to hear these bearings fitted as standard,are still running fine after a couple of years, even in that I did expect nothing else really, It do give me a bit of cheer though not having to strip the spindle out.

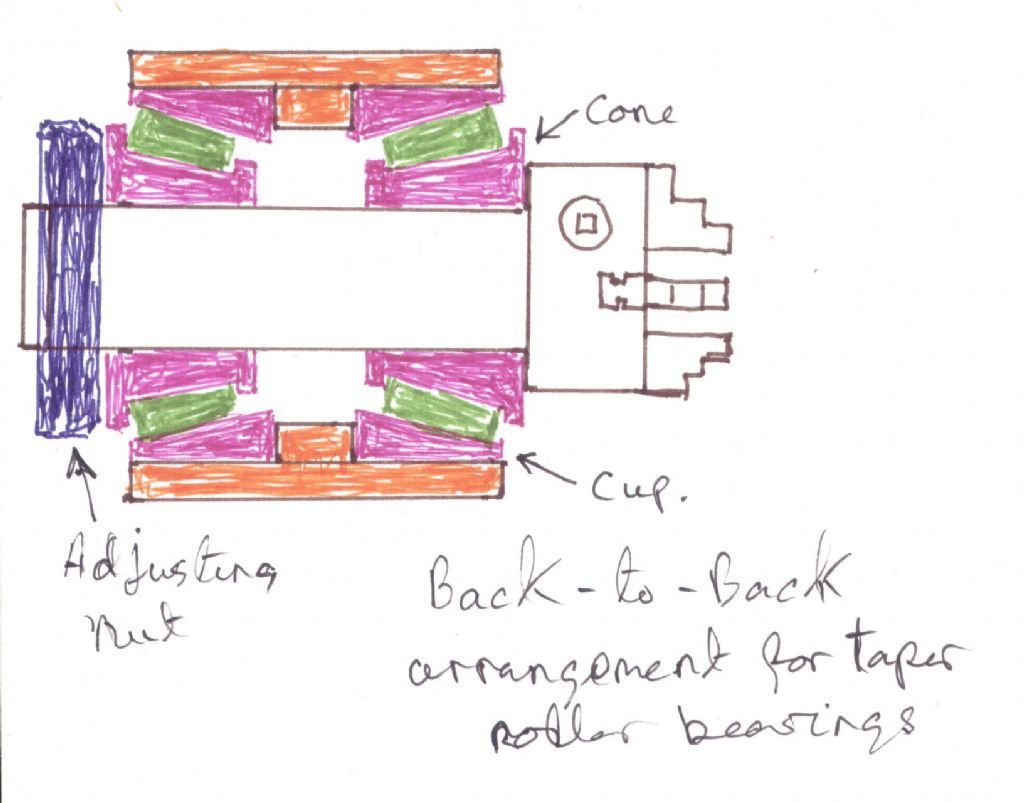

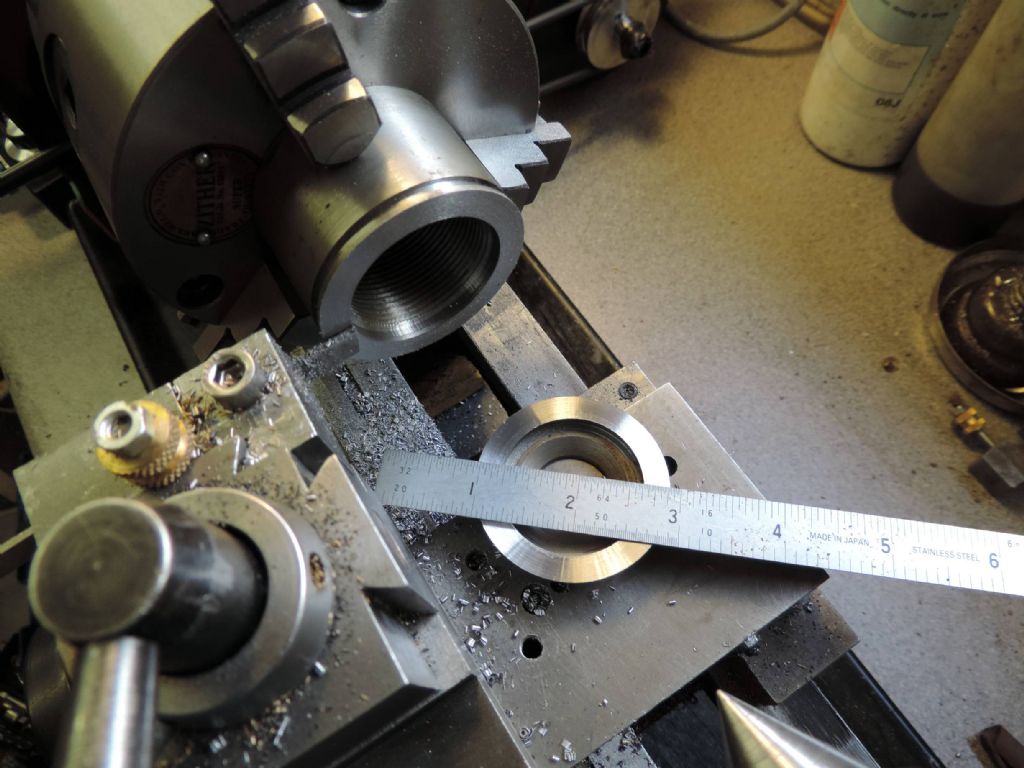

I rebuilt a Cromwell lathe going back a couple of years ago, total strip down and rebuild, I had a hard job trying to get that lathe running as true as it did before the rebuild, the bronze bush bearings were in spot on condition, so all I need to do, so I thought, was to give it all a good clean and reassemble, so easy! preload those bearings, ha ha,I know this is a different sort of bearing.over tightening by just a little will heat those bearings up and you might not even realize you have a tight spindle/shaft, could end up forever fiddling about trying to get them just right

I do know there are lots of variables involved in how we can decide/judge if this modification is at all worth doing,, things like how often the lathe is actually working under load?, the skill of the operator! what material the lathe is being made to work with, Is it mostly Brass or mostly steel, Stainless would most definitely give it a bit of hard work, also not forgetting the condition of the tool cutting edges.

I keep my finders cross and hope all stays fine

Regards

lee

Nick,

Wouldn't you say there could be a Question mark over this statement below, that in being the Skill of the machinist operating the lathe.

Ball bearings have to have a clearance in them to allow expansion and contraction during temperature changes and also for the lubrication medium, this is not very detectable to the feel on a new bearing but it is there. This is the main reason that the consensus makes angular contact bearings being able to produce a better finish etc.

Regards Nick

Neil Wyatt.

Neil Wyatt.