Have never had anything but satisfaction with Arc. Ketan and his crew are friendly, helpful, and scrupulously fair.

(Haven't met many suppliers who say "If it doesn't work out, send it back in good condition, for a refund" ).

A C3 lathe is about as much as you can lift, 40 Kg net, 50 Kg gross. It may, at first, seem bigger than you need, but you will find other jobs that are too big for a C0 or C1.

The Arc Euro Trade Catalogue is worth getting, although it will encourage you to buy more tooling / accessories.

The prices in Catalogue No 10 are now out of date, but are a useful guide.

We all have some accessories that seemed a good idea at the time!.

My advice is to use High Speed Steel tools for the materials that you are likely to use. To get the best out of Carbide tools, they need high speeds, and were developed for Industrial.are

(Already you are on the slippery slope needing a bench grinder! )

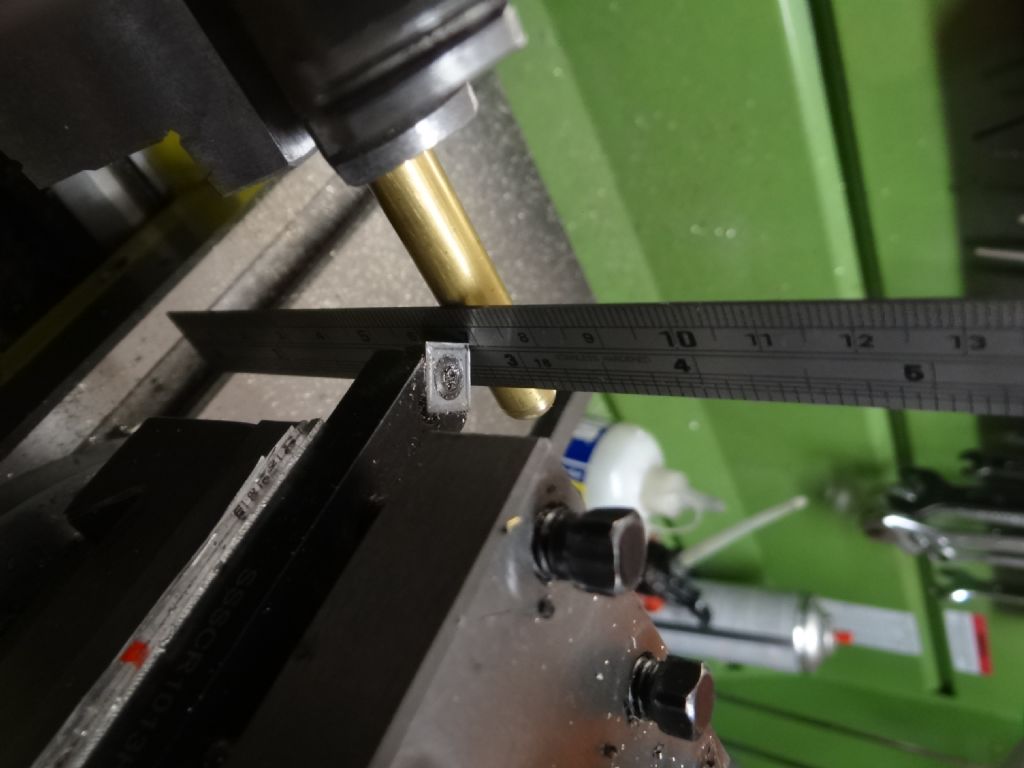

Further advice: make up a centre height gauge. It will simplify, and speed up, setting tools to the correct height, so that they cut correctly..

If you want to cut threads, other than with Taps or Dies, read up one of the books on setting up the gears, such as

Workshop Practice Series No.3 "Screwcutting in the Lathe" by Martin Cleeve, or Brian Wood's "Gearing of lathes for Screwcutting". This is very likely to lead to you making a mandrel handle , for jobs needing slow speed, and high torque.

Back copies of M E W are a good source of ideas, and methods.

Finally, do ask for advice / help on here. Advice will be given freely and if you have a real problem, the chances are that someone will be close enough to come and help in person.

Good Luck, and Enjoy!

Howard

Neil Wyatt.

Neil Wyatt.