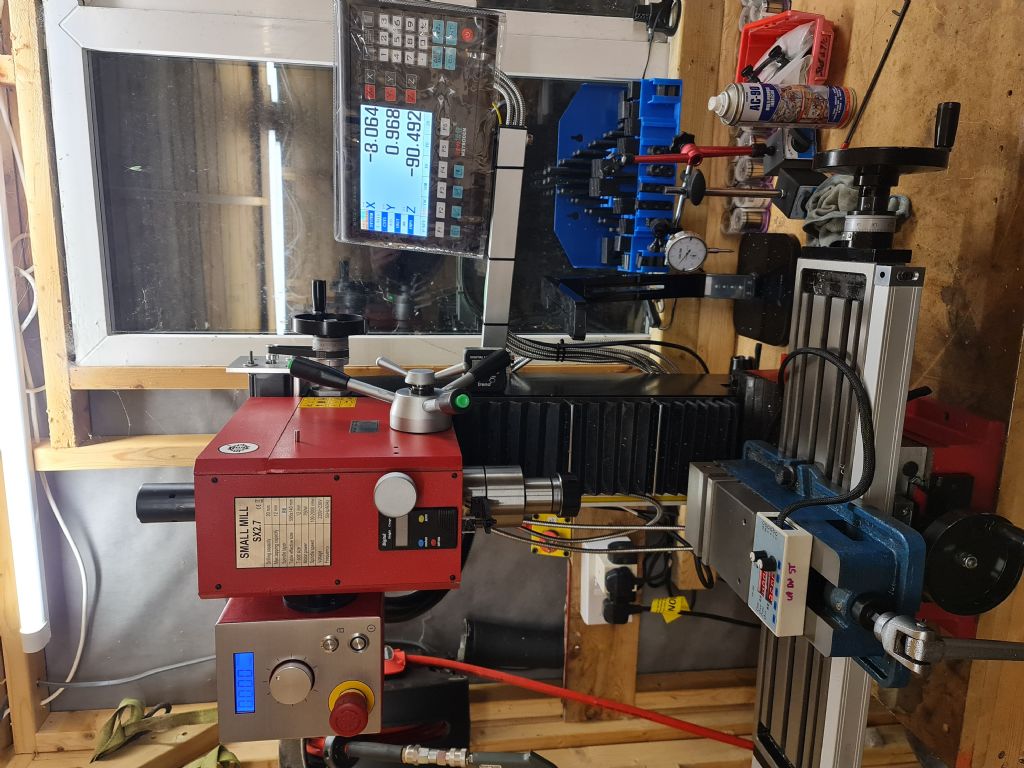

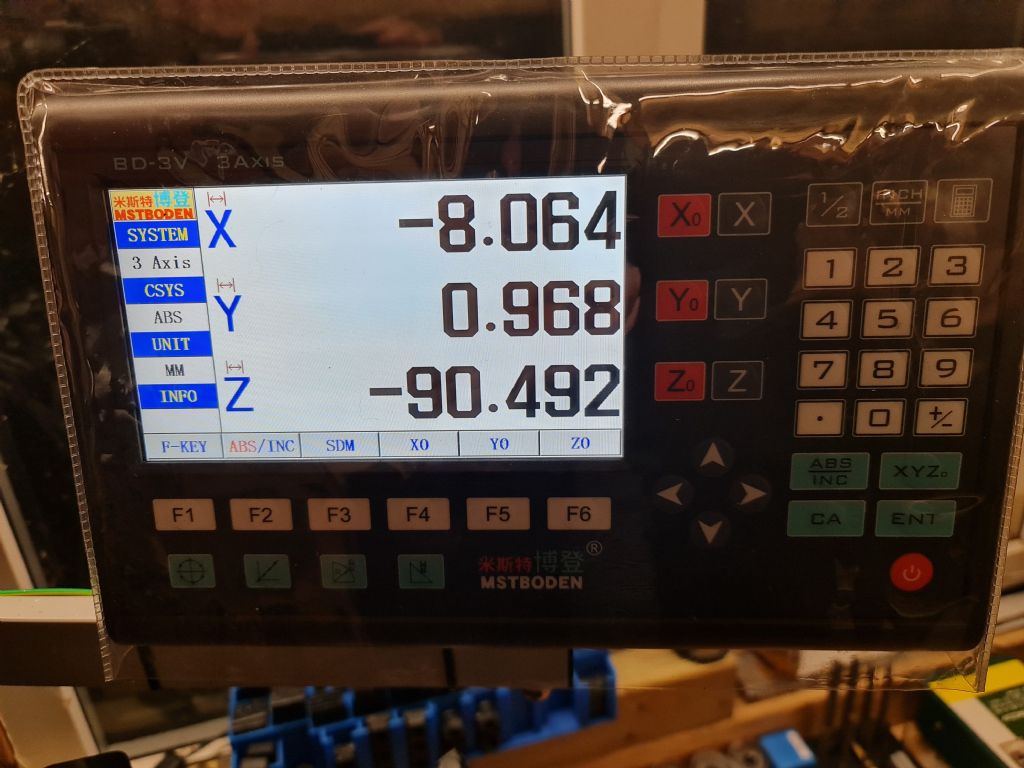

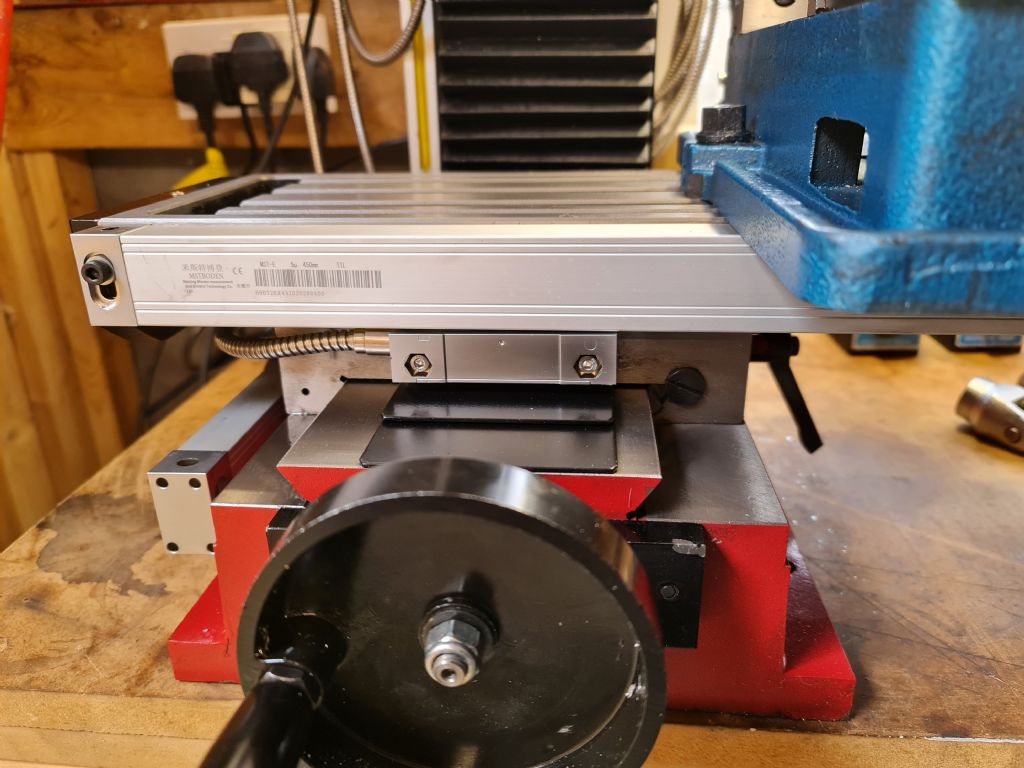

The Dro was very quick, I did pay £14 for dhl 15 day delivery instead of standard shipping, tracking said it was picked up on the 24th and delivered on the 26th!!!

Didn't hear about any import tax at all so guessing there is none to pay.

The shell mill is brilliant, I wanted the 22mm arbor but Arc were out of stock so had to get the 16mm arbor, biggest head for that is 40mm, will get a bigger 55mm one later. Got the alloy inserts and the finish it great but still need to get the steel inserts for it.

Was planning on taking pic's today but forgot, will get some tomorrow.

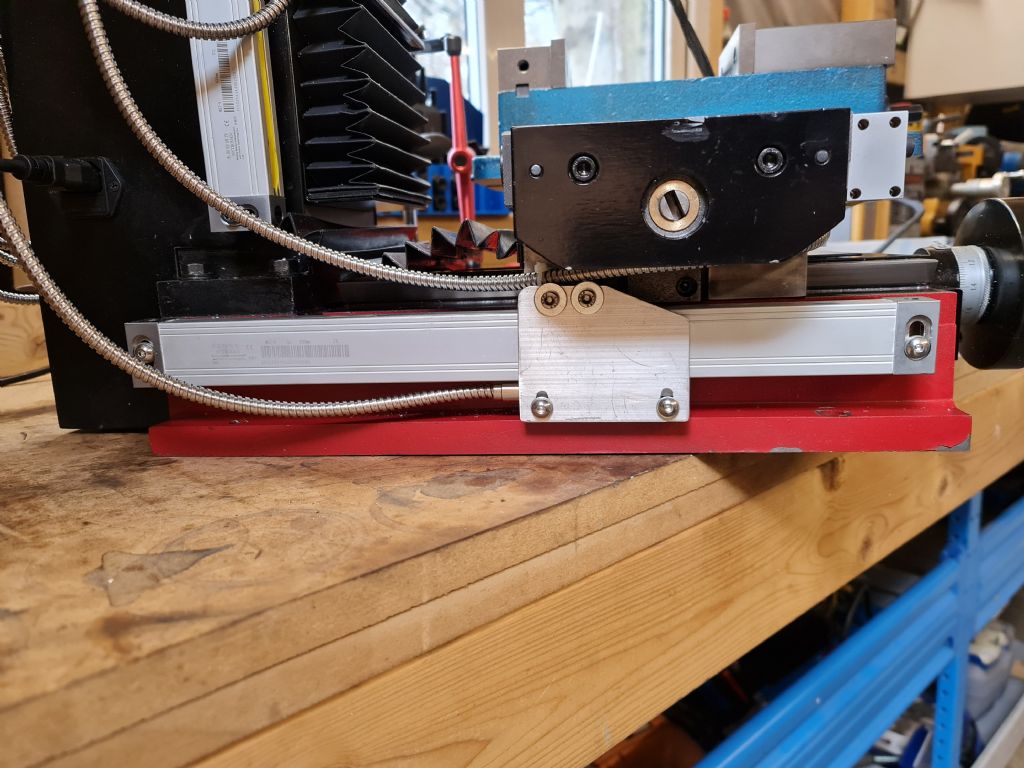

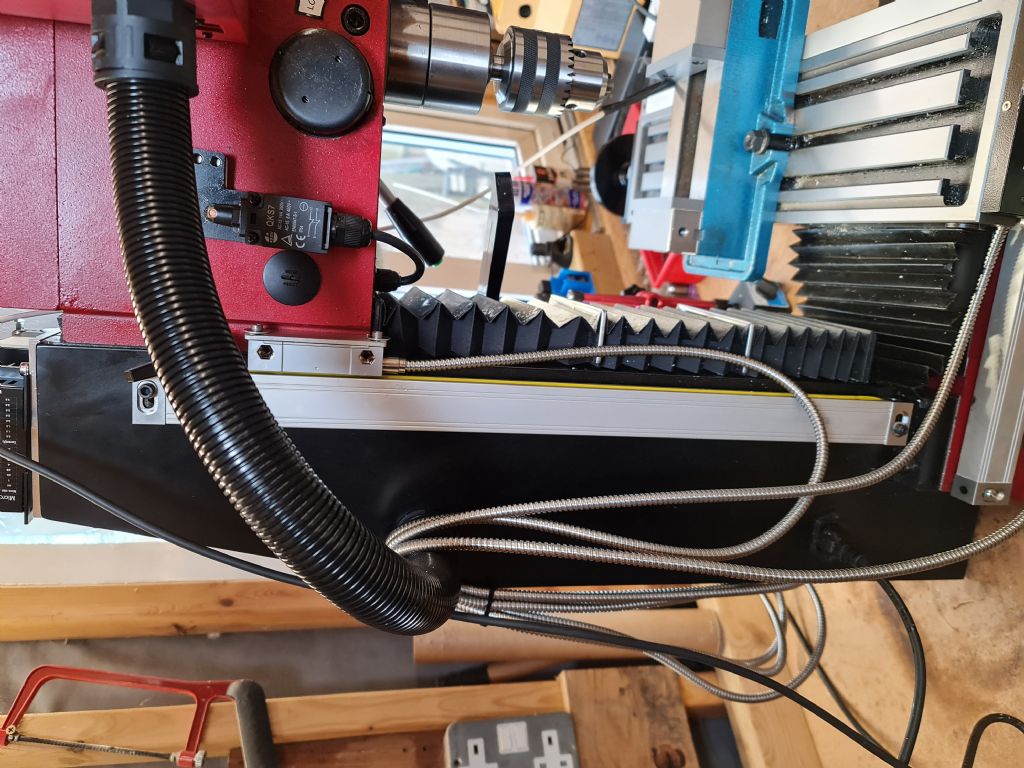

Power feeds are going to be home brew ones, nema 23 steppers, Z will be belt driven but the X will be direct drive, no clutches, will have a small amount of drag on the wheels for manual movement but I can live with that, controls will be arduino based on a system from a YouTuber, I emailed the guy and he sent me the code for his!

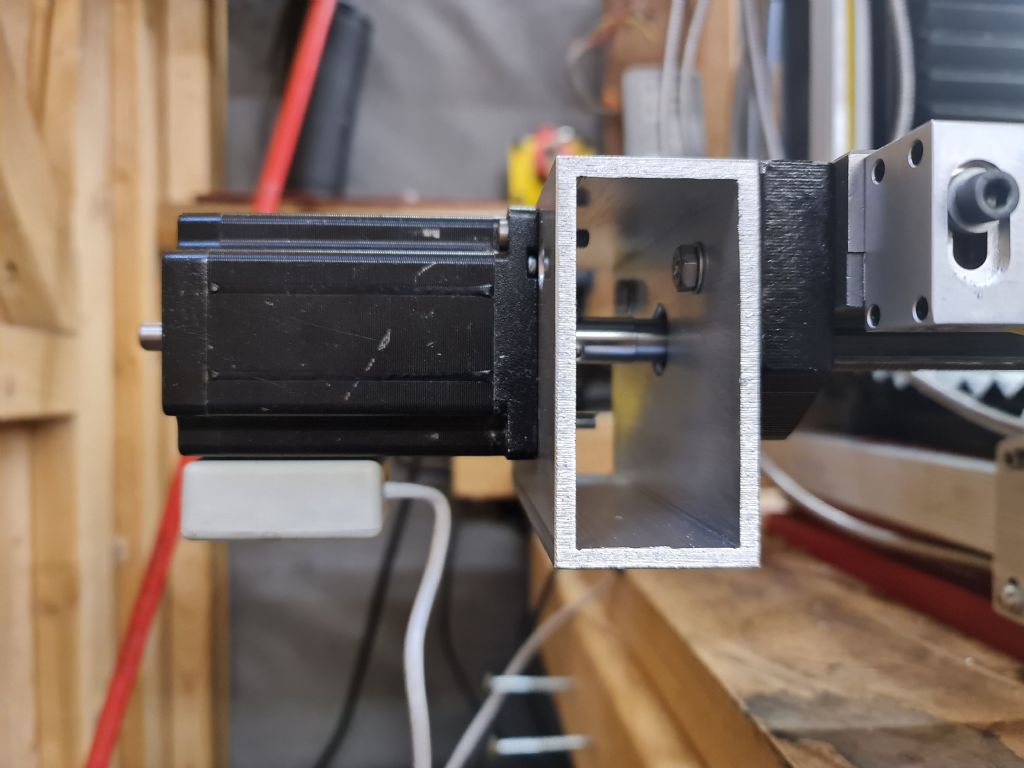

Bracket is made for the Z axis, first use of the mill in anger, god I love it, used 6mm aluminium plate cut from a bigger sheet on a bandsaw, it was so easy to square it up, drill and tap and do the slots for the stepper motor, all the holes lined up, that's a first, before the mill it was hours on the belt sander and over size holes so I stood a chance of it fitting.

I do think I'm chasing microns with the Dro, trying to get the readout exactly right !

Rotary table arrived at 9am, it was a bit rough so took it apart and cleaned it, had to do some de burning, lubed and reassembled, 0.02 backlash, no runout at all on the centre bore and maybe less than 0.005 on the table.

Used the Amazon boring bar today to cut the stepper rebate, worked a treat considering its cheap.

Few observations, the mill NEEDS a spindle lock, the pin spanner is a real pain to use and I took a few chunks out of my hand changing collet, the drill chuck arbor is very tight, to the point it is very hard to fit and remove and tapping mode occasionally won't reverse properly ((think it's a dodgy green button.

Sorry, waffled on far too long lol.

Rob

Rob Wheatley.