Thank you so much for the replies ! Every idea mentioned i have already thought about !!

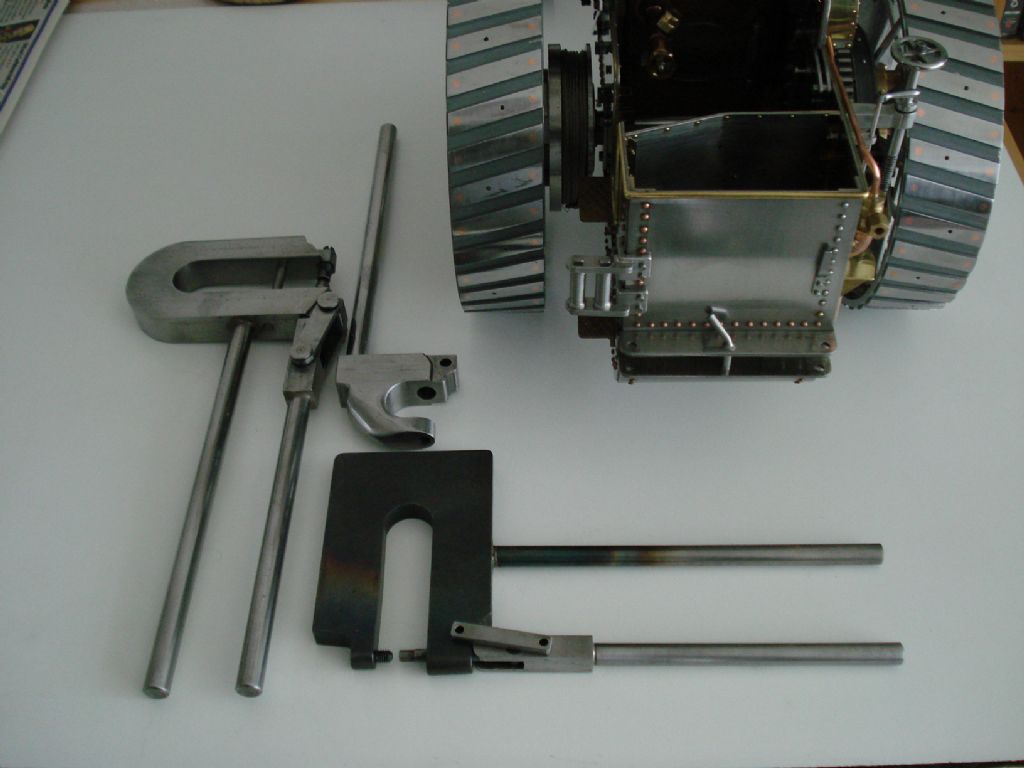

Tim S , the micrometer / hollow G clamp screw idea .. i thought of that too ! I was thinking I could use a modified automatic centre punch pushed down the hollow screw to clench the rivet ??

The existing rivets are magnetic , I would use soft copper or aluminium mig wire . Or buy some jewellery ones … I

Spot welding .. dummy rivet ..This i'm going to look at . Would the pieces need to be really clean , or would a belt of electric burn through any oxide ? Something like they use to weld Ni-cads tags together ? All food for thought..

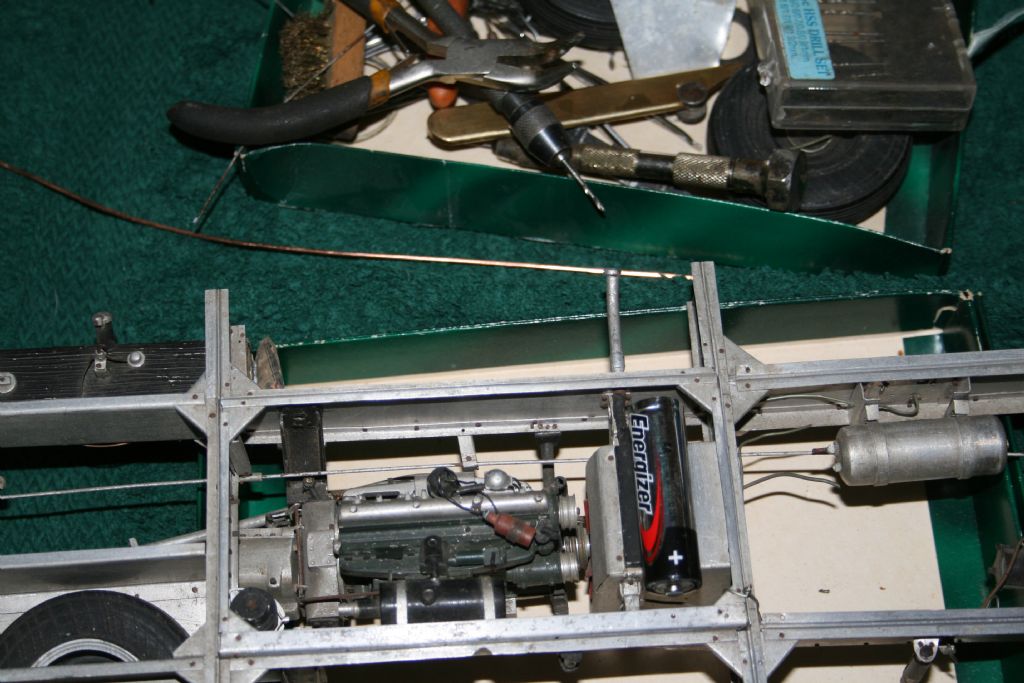

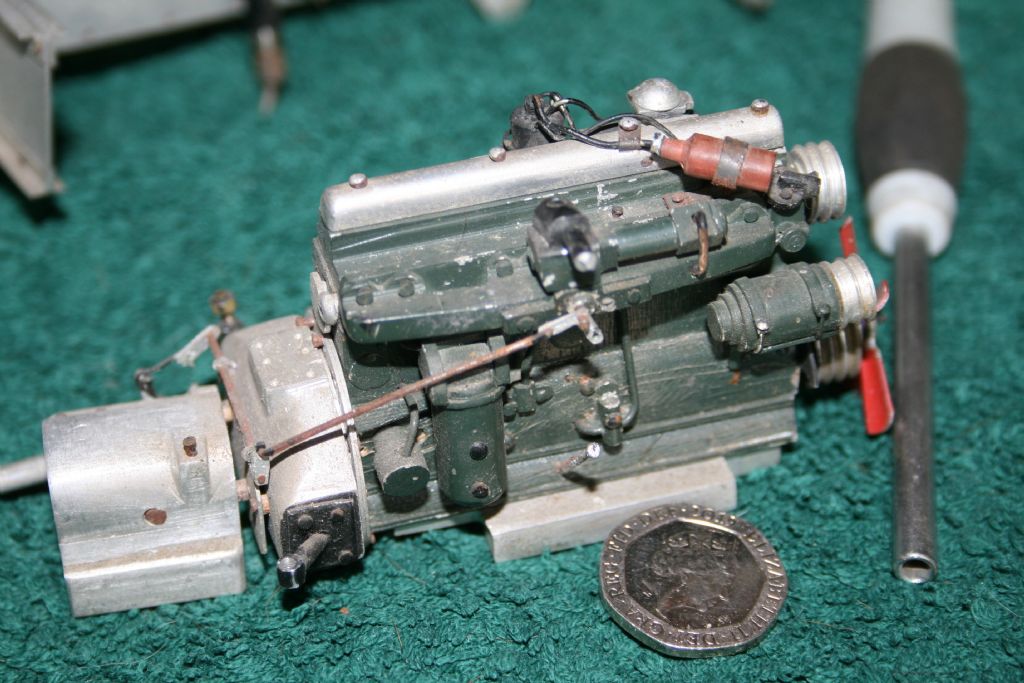

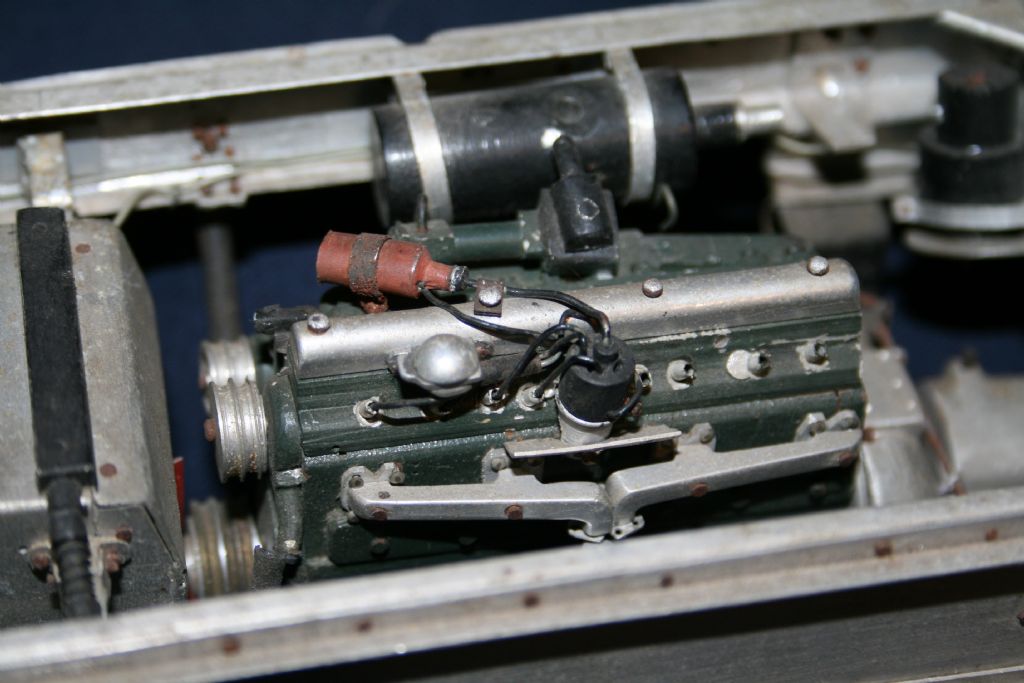

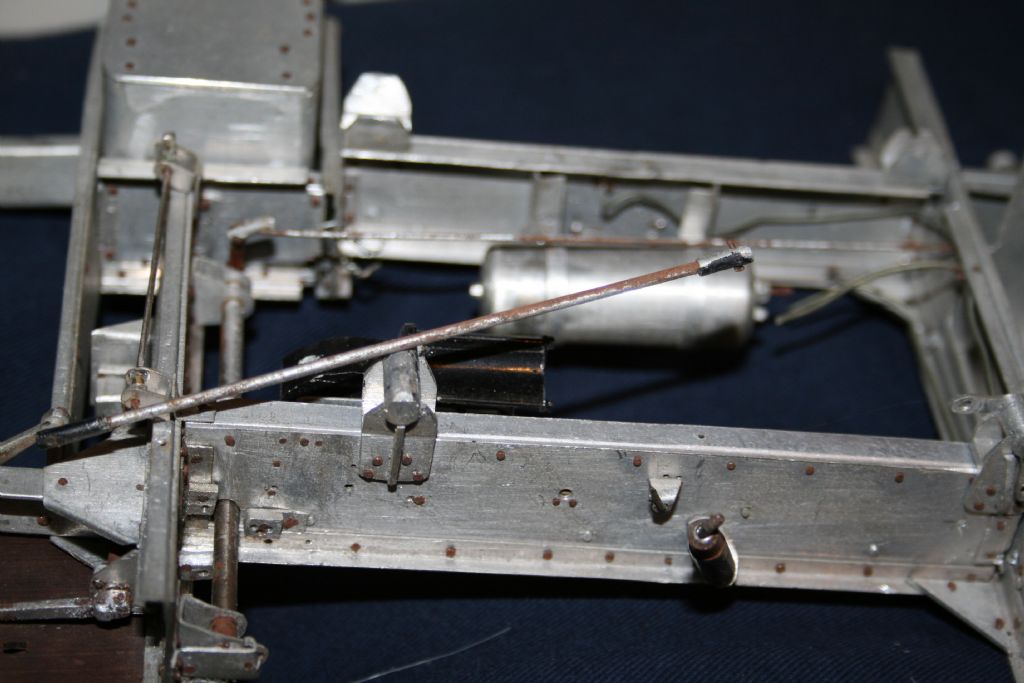

I do have a new front axle my dad made , and front springs ,wheels , dampers , steering wheel and other bits .. that were detached .

I have no interest in buses or coaches .. I paid about 40 quid for it at Maidstone Toy fair diecast swap meet , to give to my dad , around 20 years ago . He's dead now , he never did repair it … so i claimed it back ..

It is exquisite , maybe its beyond me to repair it , being honest , I would like it to go eventually to a museum or something , i suppose .

I've just seen on TV , Antiques hunt thing , from Lewis in Sussex .( I'm in love with that Christina chick..  She went to a toy train museum in Brighton.. which isn't a million miles from Hove , where Harringtons were built . Maybe i'll offer it to them at some point .. we'll see .

She went to a toy train museum in Brighton.. which isn't a million miles from Hove , where Harringtons were built . Maybe i'll offer it to them at some point .. we'll see .

Hacksaw.

She went to a toy train museum in Brighton.. which isn't a million miles from Hove , where Harringtons were built . Maybe i'll offer it to them at some point .. we'll see .

She went to a toy train museum in Brighton.. which isn't a million miles from Hove , where Harringtons were built . Maybe i'll offer it to them at some point .. we'll see .