Posted by Michael Cox 1 on 10/06/2016 15:15:32:

Timothy,

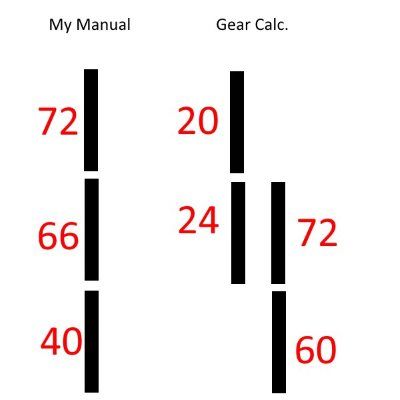

In the rows labeled "My Gears" you can put in what gears you have and any other gears that you might want to try and then see what answers come up.

Mike

Mike,

Thanks for the response, that is pretty much what I guessed.

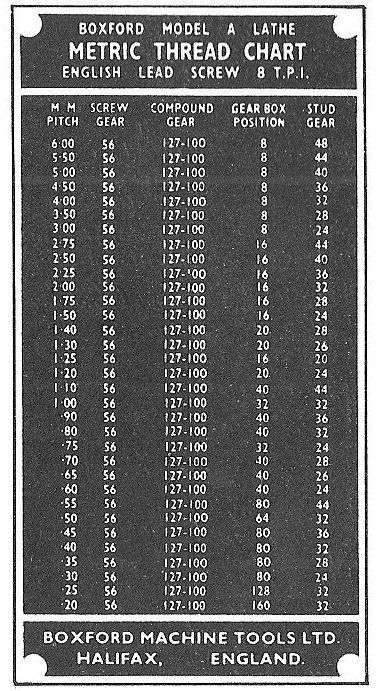

However, I would be unlikely to come up with any of my above combinations based on the standard set of 16DP 14.5 PA gears for my 4tpi leadscrew Mellor lathe (20, 25, 30, 35, 40, 45, 50, 55, 60, 70, 75, 80, 85, 90, 95, 100, 105 and 127) – I am missing 127 and all of the gears 50 and below from my set which in itself presents a challenge, I am slowly making the missing ones myself from dural plate.

The 127 gear will be the biggest challenge – at 204mm or 8" Crest Diameter it is bigger than what I can turn on my 3.5" non gap bed lathe, so I will have to make it entirely on my milling machine and rotary table.

Edited By Timothy Moores on 10/06/2016 15:40:22

Brian Wood.