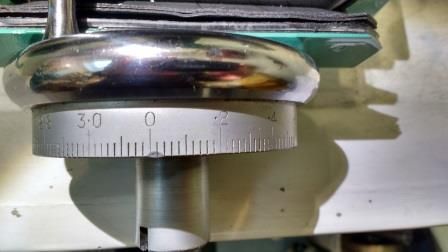

Thank you all, for the overweliming support. I did set up a dial indicator, but since my indicator only have 10 mm travel, I measured only one turn. I got really varying readings, from 3.05 per hand wheel turn, but when I measured closer to the tail stock I could see that the readings were in the 3.17-3.18 region. Not the best accuracy, and I made sure to take out the back lash when changing directions. Also the hand wheel is exactly as pictured above. (isn't it really reading 3.19 for a full turn from zero to zero?)

Could this variations in readings depending on the location be due to a worn lead screw or half nut?

So most certainly, this is a standard 8 tpi imperial lead screw, with a metric hand wheel. Was it so hard, when everything else was made metric (even the slide feed screws), to make a metric lead screw?

In any case, it seem straight forward to make metric threads with the 8 tpi lead scree, although as I understand, using the 21T gear is an approximation that works for shorter threads. I also understand that a 127T gear would be more correct. This being my first lathe experience, doing very simple things, I think this will work just fine. As a bonus I get to learn everything from scratch, instead of just twisting a few knows and not having a clue what is actually going on.

Since this is my first post, here is a little background: I am a computer engineer living in Norway, but educated in the US. I have been in the computer business for a good 25 years now, and work mostly with network security these days. I'm in the second half of my 50's now, and doing some soul searching regarding my professional life i miss the fact that I have never made anything. I'm only utilizing equipment that other people develop and produce, and thinking back on all the great stuff my fathers shop designed and manufactured, this feels some what of a void. Everything is made in China these days, and Europe is unfortunately just "cutting each others hair" as we say in Norway. So for the last few years, I have been tinkering with some electronics projects (Arduino, Raspberry Pi etc) and have built myself a small and simple lab. For the last few years, I've had a growing interest in machining. After reading a lot, and having watched countless hours of very good and interesting Youtube videos, I'm finally taking the leap into my machining adventure.

I have been looking for a lathe (and a mill) for a while, but remembered that there was an old lathe in my late fathers estate. He started is own business in the 50's, manufacturing professional electronics such as power supplies for military systems and later for minicomputers (he actually made the power supply for some of the very first computers developed in Norway), large audio mixers for broadcasting etc. Very many interesting things, and I used to work there every summer from the age of 12. They also had a very well equipped machine shop, with som very talented craftsmen. I remember this little tired lathe from my younger years, sitting in a corner of the machine shop. They used it for simpler things and the shop was full of very advanced machinery. This little lathe was the very first machine my father purchased for his newly started business. So taking this lathe into my own shop, restoring and taking it into my personal use feels very special.

I quickly found that the Myford Super 7 was a very popular machine, with many users and great help on the forums. There is also easy to get spare parts, and other options both from the Myford company (is it the original Myford company?) and other suppliers.

Thank you for all your help.

Edited By Arnljot Seem on 24/01/2016 17:46:50

Arnljot Seem.