In reply to JA's post about the hot caustic blacking. You can make up the salts yourself – they are all available on ebay. The recipe is 65 parts sodium hydroxide, 25 parts potassium nitrate and 10 parts sodium nitrite. Or you can buy commercial black oxide salts but the minimum quantity is usually 25kg.

Mix the ingredients in a suitable steel container and add an equal mass of water. Very carefully bring to a rolling boil (it can spit while heating and hot caustic salts will cause very bad burns to unprotected skin or eyes, full IPE is essential). You need to adjust the salts/water ratio so that the rolling boil occurs at between 134 and 139 deg C. Then immerse the degreased steel components into the solution for three to four minutes (or until black), then fish out the components and drop them into a jug of cold water.

The hot salts will devour aluminium before your very eyes and do not keep well – once cooled, they will absorb atmospheric moisture and grow out of their container. So once the job is done, you probably need to carefully dispose of the solution.

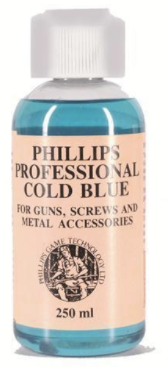

For the toolpost parts, a rust blueing process is less hazardous, will give a very durable finish, only needs the parts heating to 100 deg C and the cost of chemicals is much less.

David George 1.

David George 1.