Posted by John Rutzen on 14/03/2019 14:21:30:

…

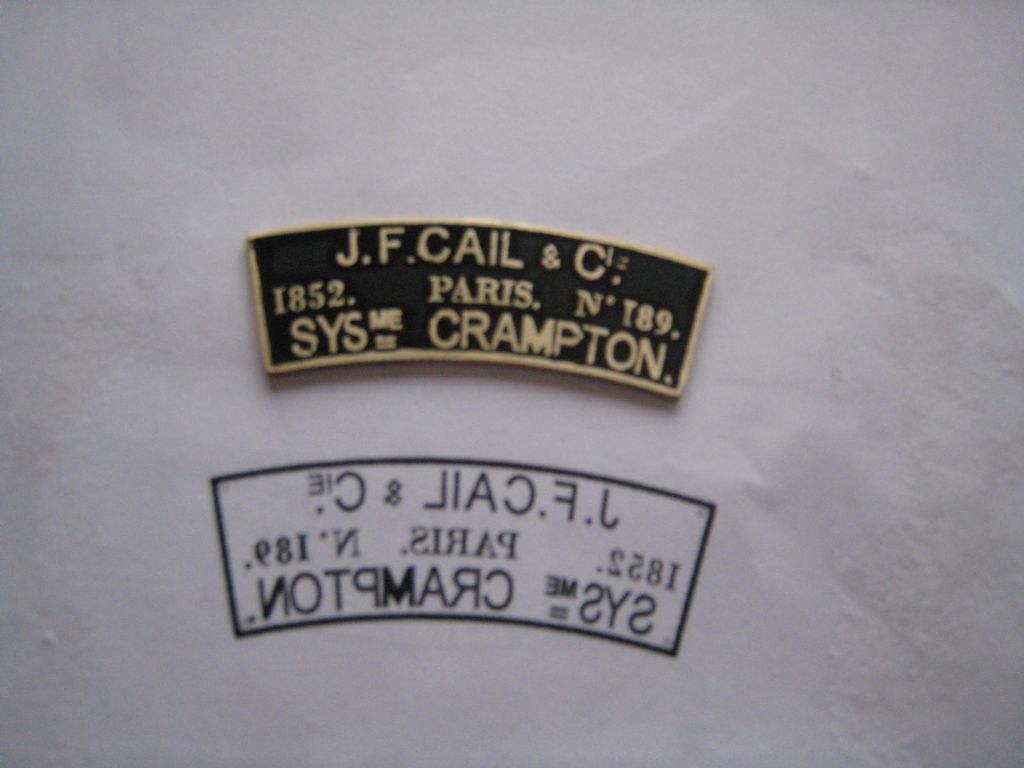

Unfortunately the only way we could reverse it and get a negative was by taking a screenshot an using that so we lost resolution.

Not sure about AutoCAD, but most CAD tools create text in blocks of fixed characters specifically so you don't get a negative when you mirror the block. It ensures text always remains readable, which is usually what's wanted.

Everything else can be mirrored, and an efficient way of producing a symmetric object is to draw one half only and to create the other side with a single mirror command.

To produce a true negative of a word you have to first select the text and Explode it . (Explode converts complex objects like text into their component arcs and lines.) Once broken into parts, reselect the whole lot and mirror that. As the components are now ordinary arcs and lines, they should mirror as wanted.

Of course once text has been exploded, you can't edit it as text any more. Double check spelling!

Dave

Diane Carney.