Posted by Bob Stevenson on 25/12/2019 14:39:19:

…

Cynoacrylate can be readily freed on delicate clock parts by gently boiling in water for about 10 to 15 minutes, where on the glue suddenly gives up. If the parts are not delicate then a small flame from a lighter will suffice, usually.

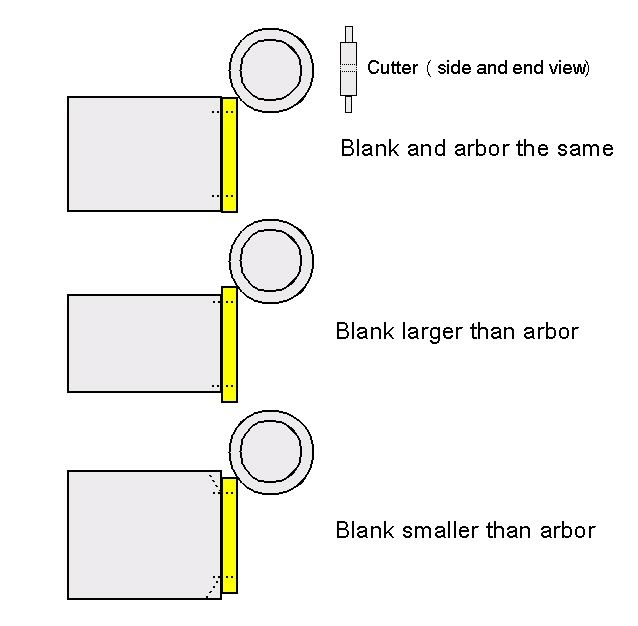

I've often used super-glue on my big lathe, the advantage being – I think – it's stronger than Shellac, comes in a convenient tube, and more likely to take big machine cutting stresses. The downside is breaking the bond after (ideally needs to be hotter than 100C), and not being able to edge the work on centre while the glue sets. Shellac overcomes the centring problem by setting slowly, but it's less convenient and the joint is much weaker than superglue.

Seems to me Superglue is the best general purpose adhesive, but Shellac takes the trick on a small lathe where the operator needs to nudge a delicate part to dead-centre, and isn't going to attack a delicate job with a roughing cutter. Otherwise, superglue is fine on a small lathe too. I can't think of a good reason for using Shellac on a big machine though?

Dave

Michael Gilligan.

Michael Gilligan.