Hello guys,

I would like to make a keyway broach guide/bushing Ø19.00mm (for a 6.00mm broach). I'm a bit stuck on working out the depth I need to cut the groove into the bushing and the reference I can use to start the cut.

My understanding is that 3.0mm of the key should engage into both the shaft and the mating part, a coupling in my case. Is the 3.0mm taken from the tangent plane of the shaft or from slightly lower where the 6.0mm key width would intersect the shaft diameter.

The highest tooth on the broach is 16.66mm and the supplied shim is 1.46mm thick, so in total 18.12mm. The broach is 9.64mm wide along its spine.

If I measure the back to back distance from one side of the motor shaft to the opposite outside face of the key I get 22.00mm.

Can I just touch off the cutter on the 19.00mm diameter of the bush and mill to a depth of 18.12mm or should it be a little deeper? What is or is there a correct way to do this?

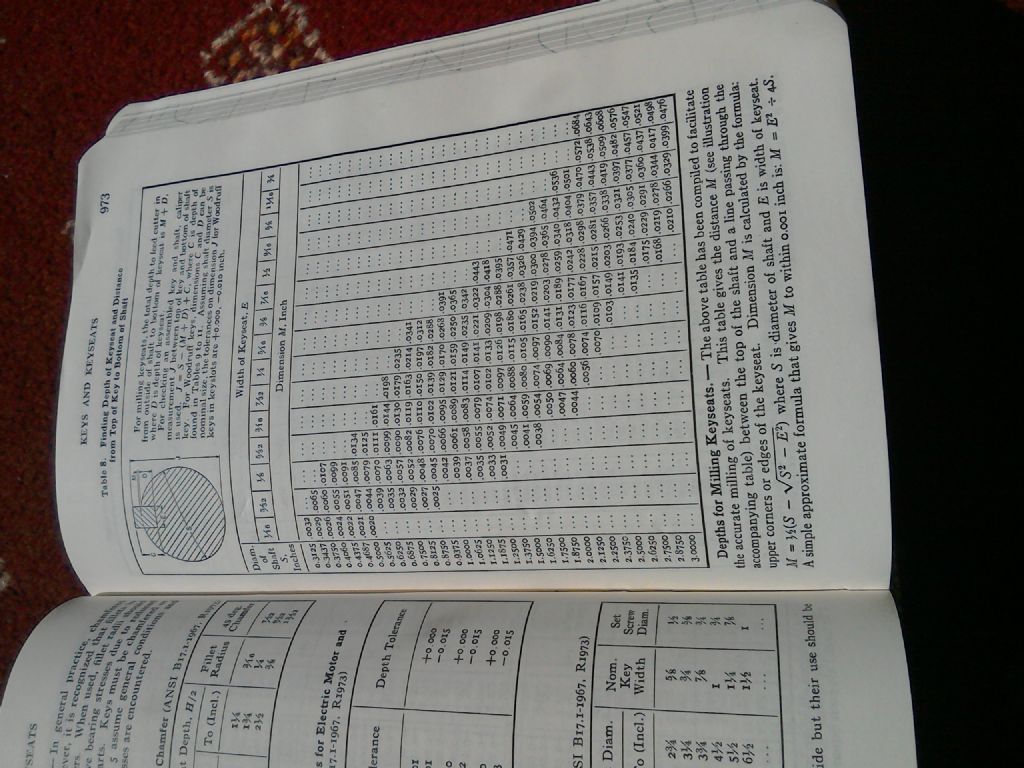

Is this the kind of info that would be in a Zeus Guide or Engineer's handbook?

EDIT: Forgot to mention, the narrow end of the broach is 14.65mm and the height of the first tooth is 15.00mm

Thanks,

Ed.

Edited By Ed Duffner on 06/05/2020 15:22:00

Ed Duffner.