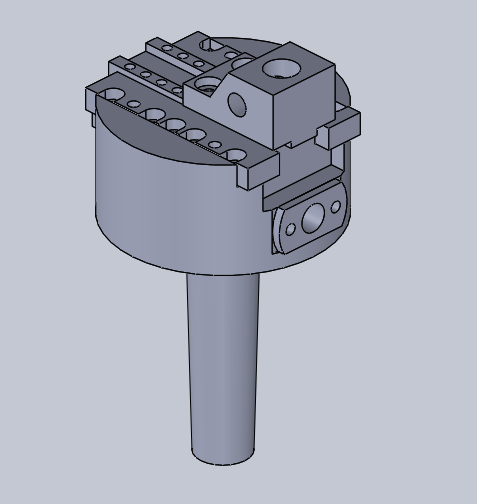

Ended up making a design, probably isn't particularly low profile but in case anyone cares I will post some pics anyways. Sadly I don't have a digital subscription either

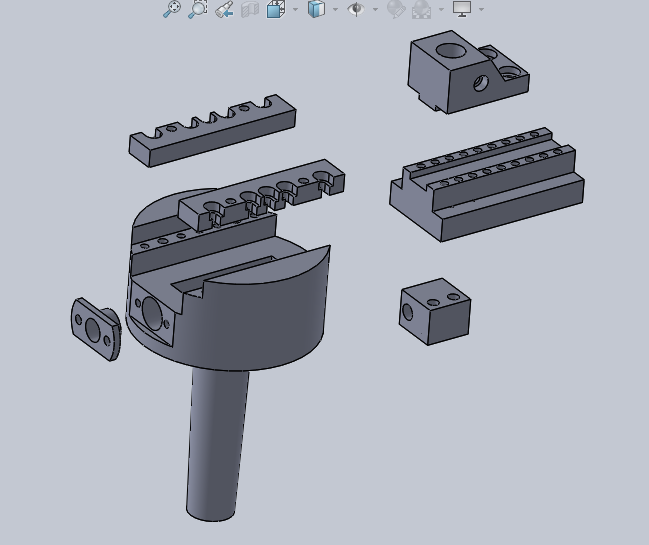

The horizontal mill doesn't like internal dovetails, I have a 60 degree cutter but it would only be able to do the exposed dovetails. Collet chuck is still on the wishlist. So instead of dovetails we have box section ways.

The pocket for the lead screw nut is going to get hogged out with a drill press and a dremel tool.

Going to use a M8x0.5 fine thread. Lets me get 0.01mm on a 10mm dial. Probably going to push a 10mm collar on to the severed head of a m4 cap head or something like that. Not fully worked it out yet. Could have a go trying to make a hex broach.

Boring bar gets locked in place by tightening the central bolt of each gib down hard.

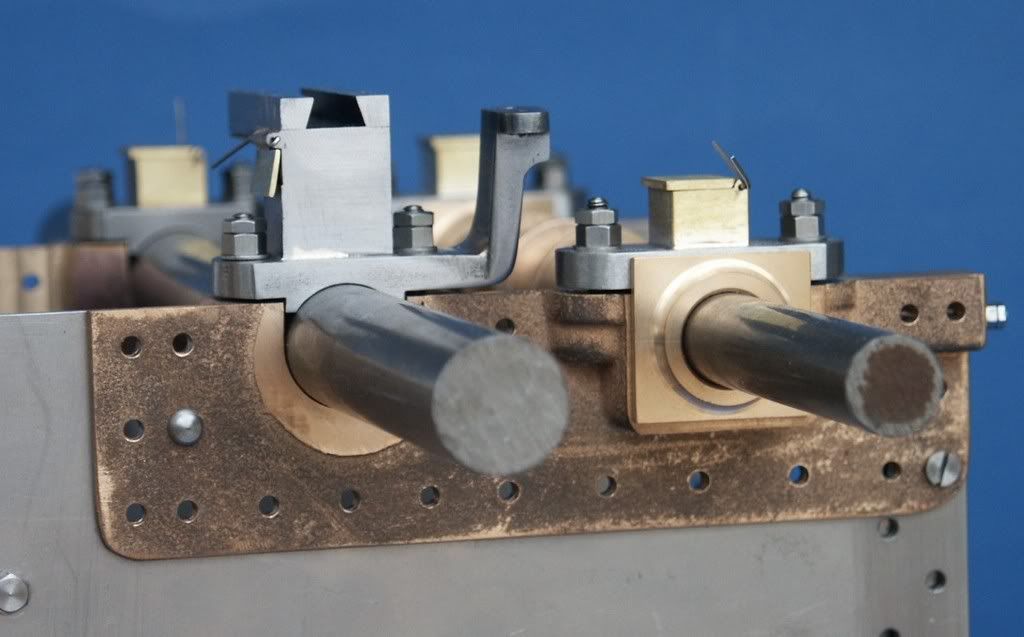

A bronze piece retains the leadscrew and locates it axially. Pretty much a copy of my lathe compound slide.

The bar is held by a cotter pin. I also have a plan for a horizontal holder for really big bores. Could add more attachments but I can't think of any of the top of my head.

Body is 80mm diameter. Total length 148mm. Length minus taper is 62.5mm. Takes 12mm bars.

Might still tweak it but thats the overall plan.

Rainbows.