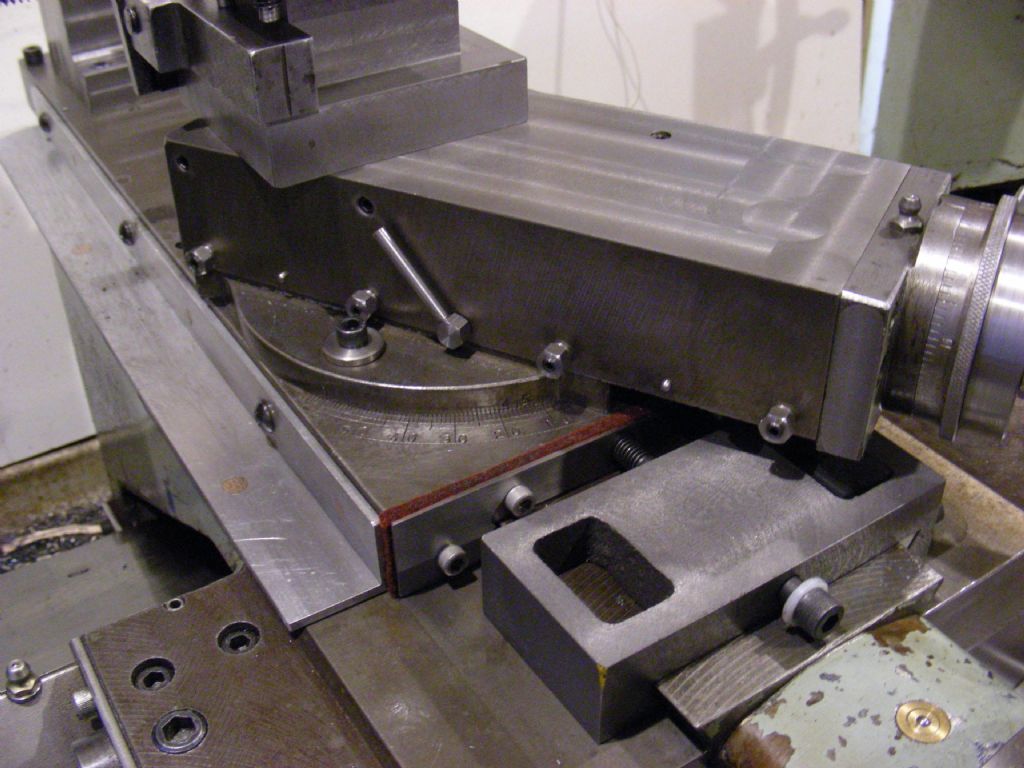

There was a recent post deploring the industry's failure to provide cross slide stops on our lathes and I was prompted by this to continue with a long-dormant project for the S7. I had considered an ingenious micro-adjustable device by Tubal Cain and other devices which looked likely to get in the way and opted for a rod projecting from the rear of the slide with a simple clamp which buts against a plate screwed to the back face of the slide:

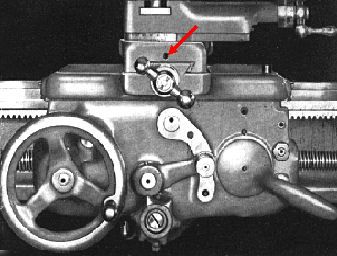

The Boxford style device mentioned above seemed suitable for the Willson slant bed (the two rectangular holes in the cast iron block are a legacy from its former role as the base to a fixed steady and are not part of the design):

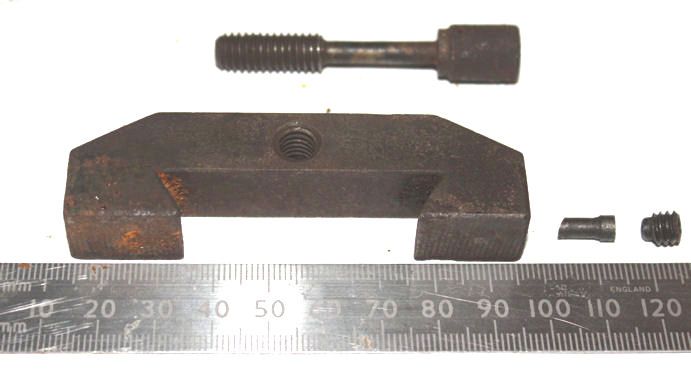

There is a potential problem with both kinds of stop in that the cross slide can "bump" the stop by a thou or so and thus inadvertently alter the infeed; the plastic washer on the cap head screw is an attempt to mitigate this. Both stops are stops are still "under development" but seem likely to simplify screw cutting with set over top slide.

The swing-up tool needs no stop, of course, but does require the ability to stop the lathe and reverse without mishap.

ega.

f:0

f:0