I emailed the Secretary, Norman Billingham, via the SM-EE.co.uk website. Norman gave me instructions as to how to pay via bank transfer. The book arrived shortly thereafter. I recognise the text as being based on earlier papers, but the book comes with a CD which contains an accompanying program which has not been available before (or at least for some considerable time). Nicely bound and presented hardback, whcih I am pleased to have in my collection. Did I say you need to love maths? The book takes a different tack to analysing the geometry than the Van Royen article, but geometry has moved on since Euclid and Van Royen.

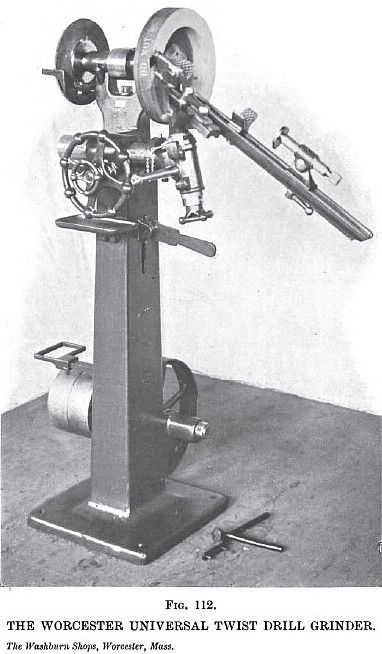

I have a fairly sizeable collection of different types of device for sharpening drills, and the Van Royen article allowed me to appreciate the geometry of the devices, especially the differences between those which require a drill projection proportional to the diameter, and those which have a fixed projection (like the difference between the Reliance and the Picador sharpeners), as well as admire the way the drill jigs have simplified or transformed the way the drill is presented to the wheel, as is common with many present-day designs.

The Van Royen geometric explanation has been repeated and cited by many writers in ME and related places, over the years. Duplex (Ian Bradley) for example, cited the analysis when he presented the reworked Potts design in ME Nov 1963 onwards (issues 3237, 3239, 3240, 3241, 3242, 3244, 3245, 3246) – ME Plan WE19). Also of interest is Ian Bradley's HoneDrill in ME Nov 1961 Vol 125 beginning with issue 3151) (a nice example of which can be seen on GadgetBuilder's site). Bardley was half of the Duplex team.

There are others of interest, such as the design for sharpening small drills, by 'Inchometer' in ME Oct 25th 1934 pp397; and the Lammas design for a four facet sharpener in ME 5 Dec 1986 and 2 Jan 1987 (although that does not deal with the geometry of conical tips, of course).

There are lots more, but the further away one gets from the Van Royen work, the more tenuous the link becomes.

You might also be interested in the article by Mazoff, freely available on the web. Not a geometric analysis in the style of Van Royen, but some interesting assertions nevertheless.

What I would like to know is: if Van Royen produced an analysis, who devised the original geometry to enable the first accurate tips to be manufactured?

Marcus

IanT.