Isn't it annoying when domestic issues interfere with important things like hobbies!

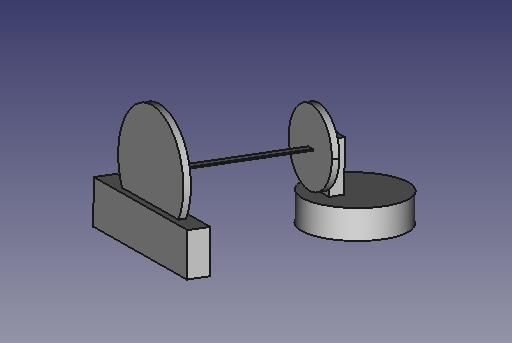

After various unexpected delays I was finally able to complete a "proof of concept" dynamometer made out of Meccano and use it today to get a reasonable result from a test Meccano electric motor.

The electric motor is considerably more powerful than a Coffee Cup Stirling engine but I think I'm on the right track: it does seem possible to make a sensitive dynamometer using the torsion bar principle. (The technique is normally used at the other end of the power range to measure the beefy Shaft Horse Power delivered by a ship's engine.)

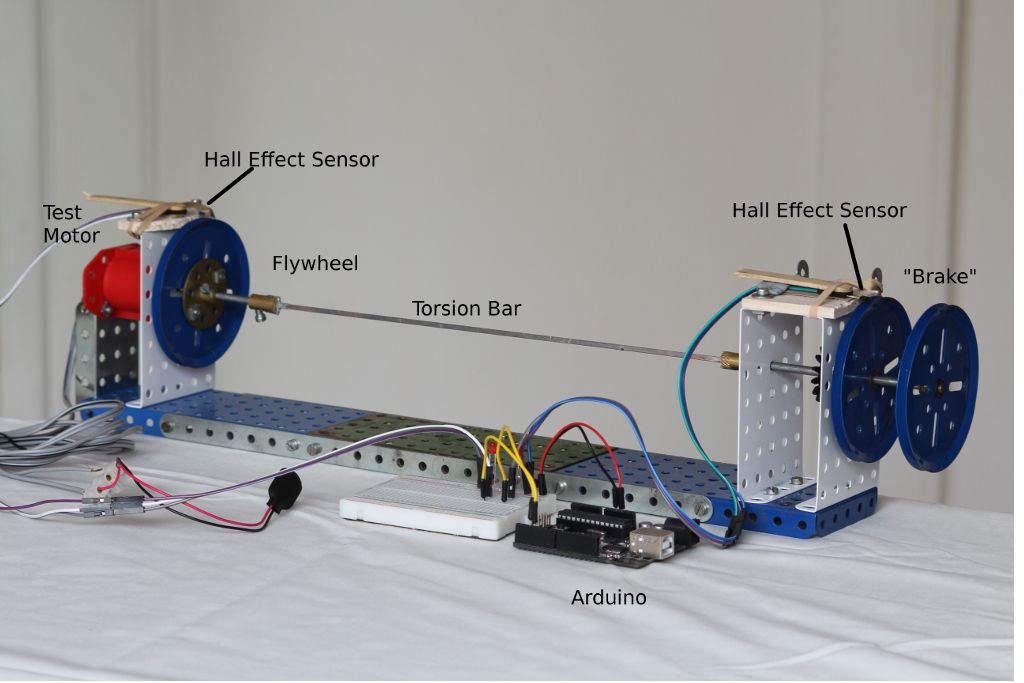

Here's the set-up:

The Arduino measures the angular displacement between the flywheel and the brake as well as the rpm of the motor. The connecting cable isn't shown but in operation data is sent to a PC for analysis through the Arduino's USB port.

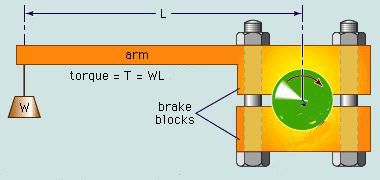

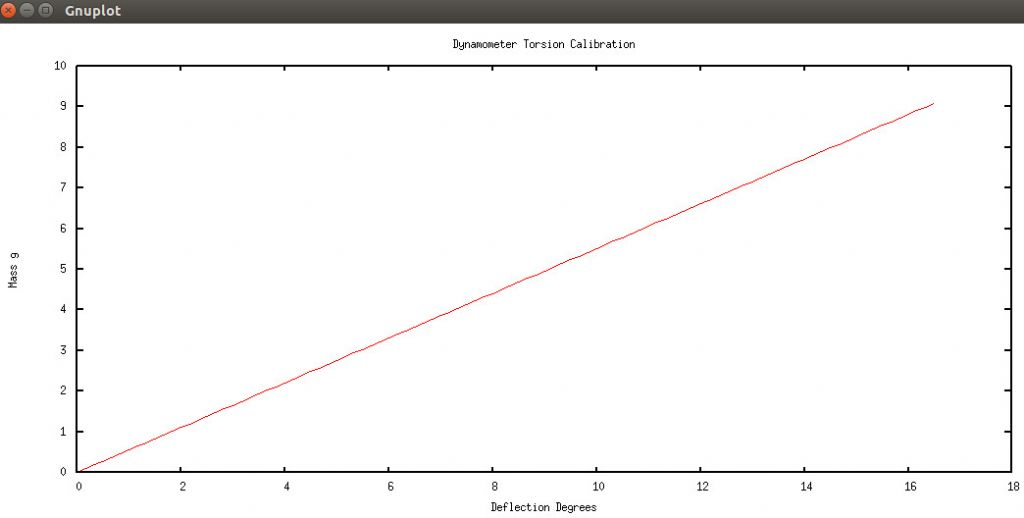

The torsion bar is calibrated by attaching a horizontal balanced arm across the brake wheel and measuring how far it is deflected by slowly adding known weights to a bag suspended from the end of the arm. I got this nice straight line graph for Torque = mass x distance.

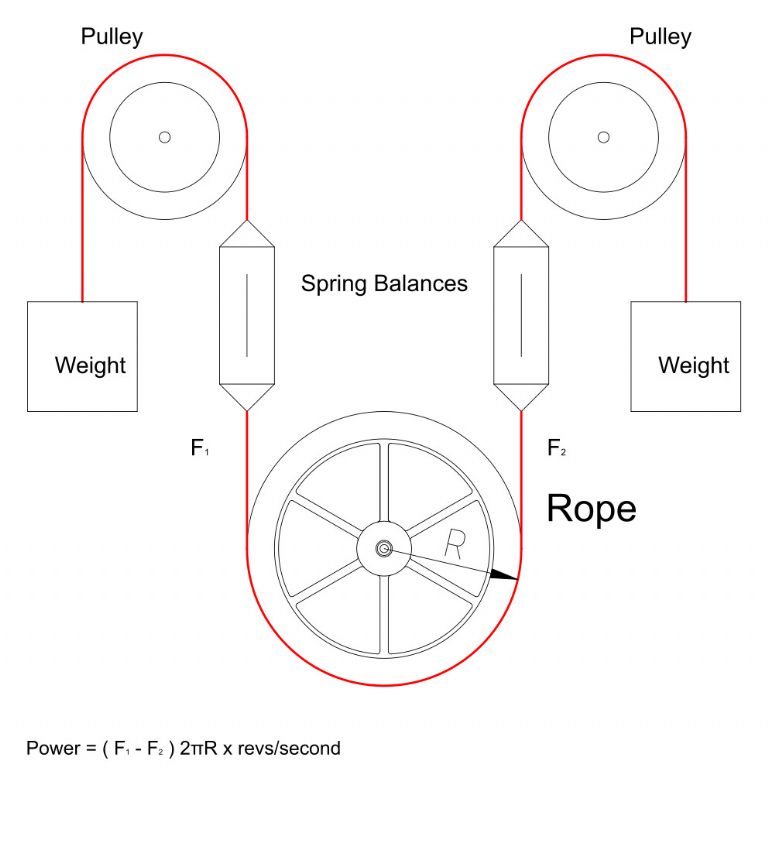

With the Arduino switched on and the PC collecting data, I laid a weighted nylon cord across the end pulley of the brake. Work is done by the motor in trying to lift the weight and in the brake's "bearings". (There's a lot of friction because Meccano doesn't have proper bearings.)

The work twists the torsion bar and because the Arduino can detect how much the brake is out of phase with the flywheel, I can determine how much the torsion bar is twisting.

After loading the data into a spreadsheet, I crunched about 100 readings to find the average deflection at average rpm. It was 1.8 degrees of twist at 365 rpm. From the calibration graph this corresponds to a torque of 0.00678 kg/m

And: Power = Torque * 2 pi * N / 60 (where N is rpm)

If I got the calculation right (oh dear!), the measured output is about 0.25W

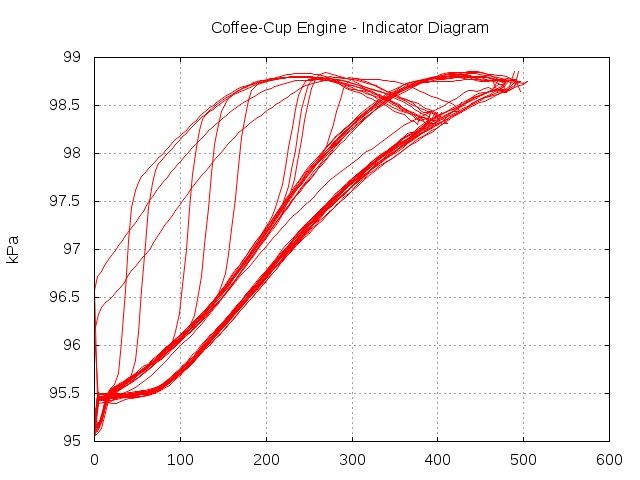

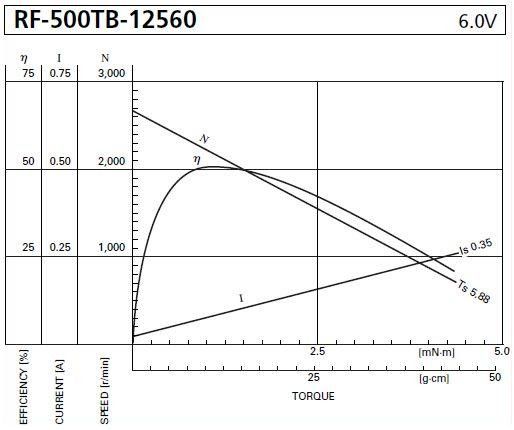

As the input to the motor was about 1W (1.75V at 550mA), we have a motor efficiency of about 25%. This is in the right ball park for a small DC motor. Below is a graph of Torgue, Efficiency, Volts and Amps as provided by the maker of a real motor. It seems that 25% efficiency isn't unusual.

There's still a long way to go with this. Interested readers will have noticed that the readings come from the extreme sensitivity end of the Meccano dynamometer. The accuracy must be very suspect. Therefore a torsion bar set-up to measure a Coffee Cup engine will need to be better engineered: I don't think I can get the necessary improvement in sensitivity from standard meccano parts.

In the hope of getting more consistent operation from the engine I've also built an "electric hot-plate" to heat the Coffee-cup engine. Actually it's a 25W 22ohm wire-wound resistor mounted in a hole gouged into half a reflective insulating brick. It's much more controllable than a mug of boiling water.

20W is sufficient to reach operating temperature reasonably quickly and 10-15W keeps the engine going. My engine is still unreliable and it may well be possible to do better than this.

As I was advised earlier in the thread, I had to replace the ball bearings with a quality type. Cheap ones just about worked but reducing friction by removing their dust-guards eventually caused the bearings to stiffen due to unconstrained up and down thrust from the crankshaft. I don't think it's good when miniature bearings start making crunchy noises!

The engine runs noticeably faster with better bearings but I still have a friction problem. It may be that the steel piston is binding in the brass cylinder due to unequal expansion as the engine warms up. I'm suspicious that the odd bit of "brass" I used to make the cylinder is actually bronze. Would bronze be bad news in a cylinder?

Cheers,

Dave

Edited By SillyOldDuffer on 07/04/2016 16:36:48

Ian S C.