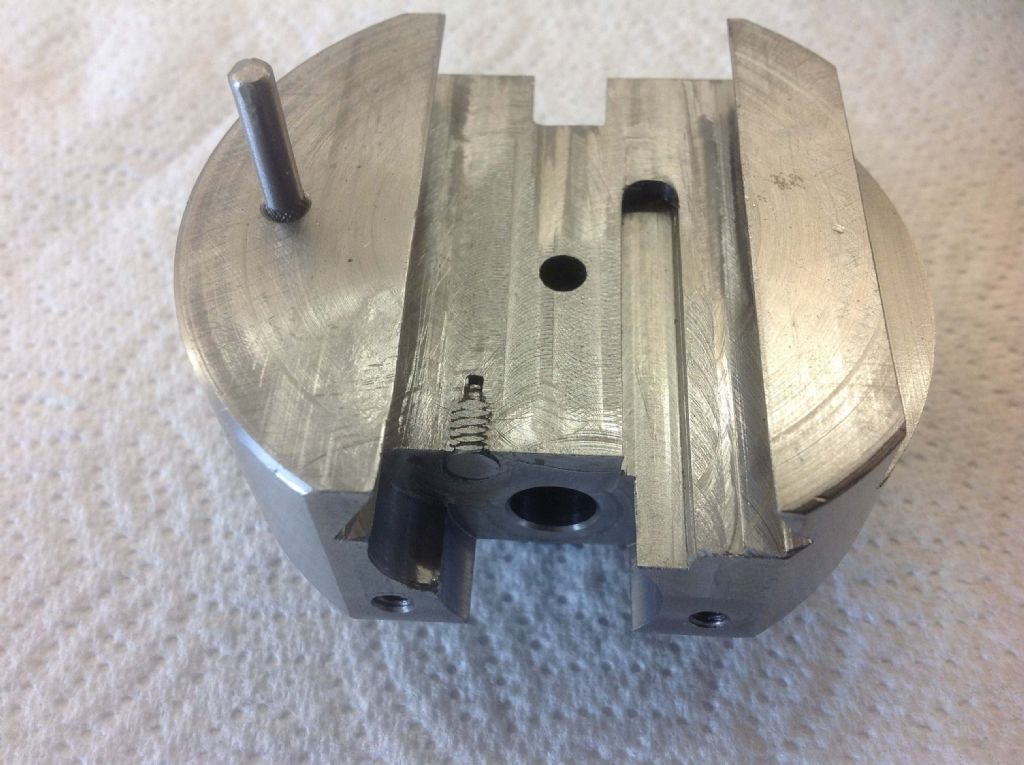

I bet you're all busting to know what cock-up I'll make next, aren't you? Decided to try the Michael Gilligan approach first and did as Geoff suggested and clamped a bit of steel to the edge before tapping. As I've only got a plug tap in 6mm, I had to go a bit careful-like. Didn't want to end up with a broken tap end to get out as well. As a consequence, I couldn't get right to the bottom of the hole, but near enough. After a clean up with an end mill, I'm at the stage you see below:

Not pretty, I grant you, but I console myself with the fact that it doesn't take any great strain in operation, serving only to locate the idler gear; neither will it be visible when assembled. Unfortunately, I know it's there and I can't erase that from my memory. I might even pop a bit of J-B weld in for cosmetic reasons! Now that would be ironic!

I'm taking a rest from the garage to watch a bit of Wimbledon, but I hope to continue the saga tomorrow.

John

John Hinkley.

John Hinkley.