Andrew: having tried to get some information on your inserts, I am in some confusion, because I can’t get any consistent information! JTS have the –AK chipbreaker down as medium and heavy cuts:

• Feed Rate = 0.004 – 0.020 ipr

• Depth of Cut Range = 0.050 – 0.200 inch

whilst their link to ‘Triumph Chip Control’ gives:

• Feed Rate = 0.001 – 0.020 ipr

• Depth of Cut Range = 0.004 – 0.200 inch

which happens to be the same as on the Toolmex site, where it’s classed as ‘light to medium’! But according to the Korloy website at:

**LINK**

it sits nicely between the two (for both 0.4 and 0.8mm tip radius) at:

• Feed Rate = 0.002 – 0.010 ipr

• Depth of Cut Range = 0.012 – 0.140 inch

Whilst on another page of the same Korloy data sheet it says max feed 0.020” and max depth 0.160”. So which is it? G.O.K.!

Now I don’t have much experience of aluminium inserts, so I’m a bit out of my comfort zone here, but I think it’s a good guess to say that they will be designed to produce short curly or comma chips, so as to provide easy clearance from automatic machines. Long continuous spirals would not be popular as the machine would have to be stopped to rake it all out, and tangled stringy swarf would be as welcome as a f**t in a lift. Bearing that in mind, together with the Sandvik diagram of chip formation, your recent tests show that everything is going according to plan, and perhaps provides some clues as to why it’s the wrong plan!

You’ve been working at the left hand edge of the envelope shown on the first page of the Korloy data sheet, perhaps even a bit left of it – marginal conditions for long spirals, so that it only takes a bit of a hiccup at the tool tip to throw it further left and get into stringy mode. Perhaps just build up of aluminium on the surfaces across which the chips must travel, as in this photograph of the Sandvik tip I mentioned earlier – used tip at the top, unused at the bottom:

Moving rightwards on the diagram by increasing the feed might serve to get it away from marginal conditions, hence the good spirals at 0.012” feed. That, together with your doc of 0.010” puts the conditions more or less in the middle of the Korloy diagram, so I would have expected it to be forming non-continuous chips – so why is it not doing that?

I don’t know the answer, but suspect a clue might lie on the left axis of Korloy’s diagram – cutting speed might be too low to smash the chips hard and fast enough against the breaker bits of the tip to actually break up the spiral. You’re down at 25% of the recommended cutting speed, so I’d have a go at higher cutting speed.

Of course, if you’re happy with continuous spirals at doc 0.050” and feed 0.012”, then you’ve found your solution. But if not, here’s something else you can try to find, in a logical manner, what would suit you:

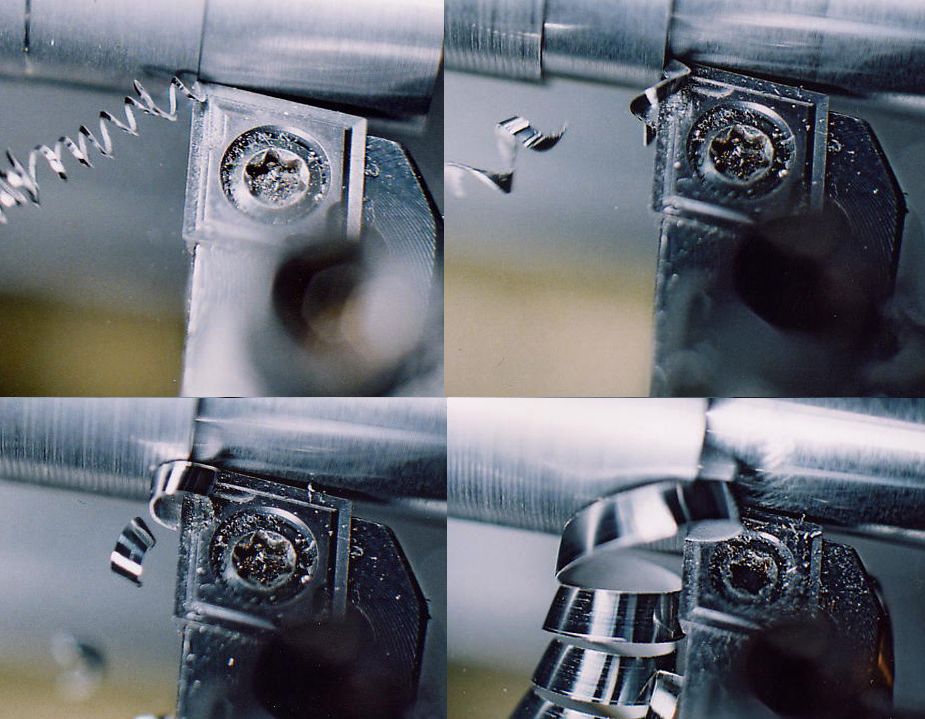

Say you’re happy with doc 0.010” or steps thereof. Turn a bar down in 1” long steps with doc .010” for each step. Whilst doing this, try different feeds for each step until you find a satisfactory chip formation. Set this as your feed. Then turn the whole length parallel at that feed, so doc increases in 0.010” steps as you proceed along the bar. With a bit of luck you’ll hit gold. The following photographs show this process for a Sumitomo tip cutting steel at feed 0.004”:

Top left – doc 0.005”

Top right – doc 0.015”

Bottom left – doc 0.025”

Bottom right – doc 0.120” feed 0.002”

These piccies also show exactly how the Sumitomo breaks the chips. In the first one the thin spiral is formed by the primary cutting edges, but the spiral runs away from the tip without further contact and remains as a spiral.

For the second two, look at how the chip breaker grooves are working – the thicker spiral from the primary cutting edges first contacts the chipbeaker formations, which deflect it downwards so that the spiral now contacts the leading edge of the chip, where it gets broken into bits.

In the last one, the same thing happens, but the spiral is now strong enough to resist fracture.

Anonymous.