This is an excerpt from Rolts book, must have been quite a machine for that day and age.

Mike

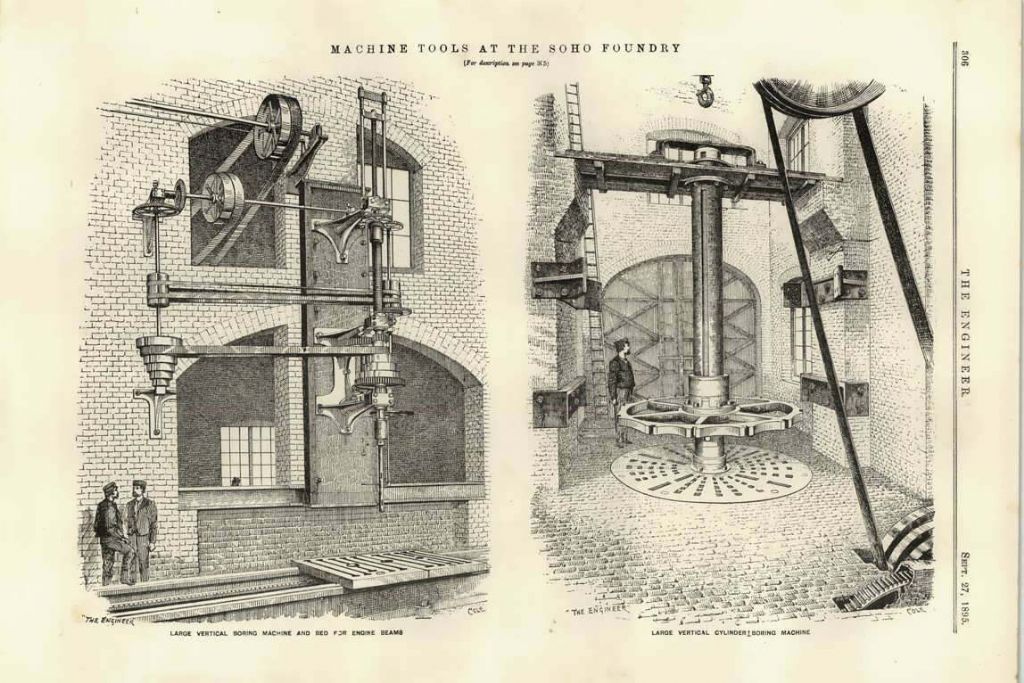

A new and much heavier boring mill was constructed and the boring bar for this was supplied by the Lowmoor Ironworks in May 1799. It weighed 3½ tons and may well have been the bar which was still lying in a disused state at Soho in 1895. If so, it was hollow, 17 feet 6 inches long, 16 inches in diameter and 4 inches thick. Presumably it was originally fitted with a form of rack feed to the cutting head because Murdock was not responsible for introducing lead-screw feed as has sometimes been stated.

A 64-inch cylinder was the first to be bored on this massive machine and a record of the operation has been preserved to show what a lengthy and laborious business it was. It reads as follows:

Getting on, ¾ day.

Centring and fixing, 1½ days.

Facing, ½ day.

Setting Cutter, ½ day.

Boring, 11½ days.

Preparing to go through a second time, 1 day.

Boring, 8½ days.

Facing, 1¼ days.

Bell-mouthing, 1½ days.

Getting off, ½ day.

Total, 27½ working days.

Mike Poole.

Mike Poole.